What Are Dynamic Adaptive Vibration Isolators?

Dynamic adaptive vibration isolators are next-generation systems designed to sense and adapt to changing vibrations in real time. Unlike traditional vibration dampers that have fixed properties, these smart isolators can alter their stiffness or damping on the fly to maintain optimal performance. Essentially, they act like “intelligent shock absorbers” that tune themselves to cancel out unwanted shakes as conditions change. For example, a recent design incorporates a stiffness-adjustable structure with sensors to detect the incoming vibration frequency and an intelligent controller that switches the isolator between soft and stiff settings in real timenature.com. Analogous to the human body’s reflexes, the system perceives external vibrations and responds instantaneously, offering broad-spectrum vibration control rather than working well only in a narrow band nature.com. This ability to adapt differentiates dynamic isolators from conventional static mounts and enables protection against a wide range of vibrational disturbances.

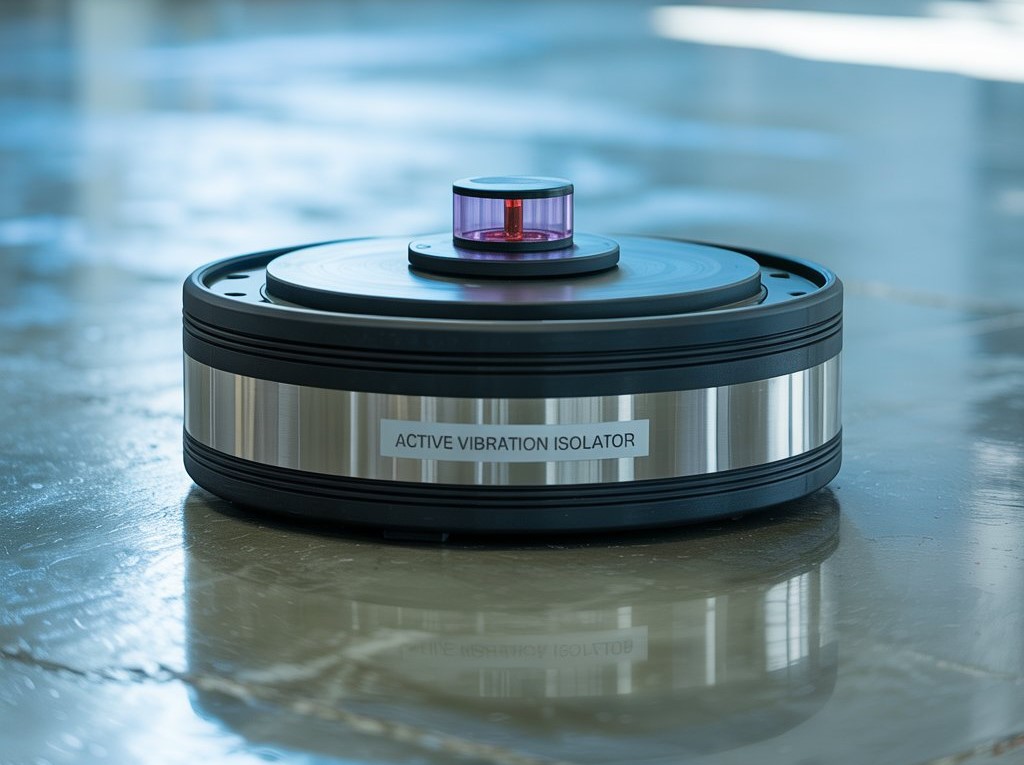

These isolators come in various forms – some use electronic feedback and actuators (making them “active” systems), while others leverage smart materials or novel structures (often called “semi-active” or “adaptive” systems). The key idea is that they don’t remain passive when vibrations change. Instead, they adjust themselves (changing their stiffness, damping, or even applying counter-forces) to continually minimize the transmission of vibration. This is crucial because vibrations are an invisible threat across many industries – from semiconductor fabs to aerospace – where even tiny oscillations can cause errors or damage daeilsys.com, azonano.com. As one industry expert put it, “controlling invisible vibrations is no longer a luxury, it is a strategic imperative” for modern high-tech operations daeilsys.com. Dynamic adaptive vibration isolators have emerged as a cutting-edge solution to meet this challenge.

From Traditional Isolation to Adaptive Control: Key Differences

Traditional vibration isolation systems (like simple spring-damper mounts or rubber pads) are passive – they have fixed stiffness and damping tuned for an expected vibration range. They work on the classic principle that when the vibration frequency is well above the system’s natural frequency, the isolator will significantly reduce transmitted vibration nature.com. This works fine for certain conditions, but it comes with trade-offs. A conventional passive isolator must be soft enough (low stiffness) or supporting a heavy mass to isolate low-frequency vibrations, yet stiff enough to carry the load without sagging. This creates a design contradiction between achieving a low natural frequency (for better isolation bandwidth) and maintaining load capacity nature.com. In practice, engineers often have to either reduce stiffness or increase mass to widen the isolation bandwidth, which can lead to bulky, heavy systems nature.com.

Even with clever passive designs, there are limits. Many passive isolators suffer a resonance peak near their natural frequency where vibrations actually amplify instead of attenuate nature.com. Techniques like High-Static-Low-Dynamic-Stiffness (HSLDS) supports (which introduce negative stiffness elements) and Quasi-Zero-Stiffness (QZS) mechanisms have been developed to push the natural frequency as low as possible nature.com. These have improved the performance of passive isolators by broadening the range of isolation at low frequencies. However, they too can exhibit resonance or reduced efficacy outside their ideal range nature.com. In other words, passive solutions are fundamentally limited – they’re tuned to one scenario and can’t adjust if the vibration characteristics change (for instance, if the frequency of disturbance shifts or the load on the isolator varies).

Dynamic adaptive isolators break this limitation by introducing real-time adjustability. They often incorporate sensors to monitor vibration input and feedback mechanisms to adjust the isolator’s properties on the go. A traditional passive mount might become a liability if an unexpected vibration excites its resonance. By contrast, an adaptive isolator can detect that it’s nearing a harmful resonance condition and instantly stiffen or soften to avoid it nature.com. As a 2025 study pointed out, achieving “intelligently excitation-adaptive (IEA) capabilities in real time” – the ability to switch an isolator’s stiffness or mode on demand – is seen as the primary challenge and goal in advancing vibration isolation technology nature.com. In effect, adaptive isolators eliminate the one-frequency trade-off of passive designs. They aim to offer wide-band isolation, protecting against low-frequency drifts and high-frequency shocks without the usual drawbacks (like extreme softness causing sag, or narrow tuning). This makes them particularly suited to environments where vibration profiles vary widely or cannot be perfectly predicted in advance.

How Adaptive Vibration Isolation Works (Science & Engineering Made Simple)

So, how do these smart isolators actually adapt? In most cases, sensors + controllers + adjustable elements are the recipe. The isolator is equipped with one or more sensors (accelerometers, displacement sensors, etc.) that continuously measure the vibrations affecting the system. These sensors feed data to a controller (essentially a small computer or circuit) that uses an algorithm to decide how to counteract the incoming vibrations. The “muscles” of the system are actuators or adaptive components that can change the isolator’s mechanical properties on command.

One common approach is to use electromechanical actuators. For example, an adaptive isolator may include an electromagnetic device (like a coil and magnet) in parallel with a spring. By changing the current in the coil, the device exerts a variable magnetic force that effectively changes the stiffness of the system nature.com. When the vibration frequency shifts, the controller can dial the current up or down, switching the isolator between a “soft” setting and a “stiff” setting optimized for the new frequency range nature.com. This was demonstrated in a recent prototype that could switch between a low-stiffness mode (to isolate low frequencies) and a high-stiffness mode (to suppress resonance), thereby maintaining protection across a broad spectrum nature.com. The science here is basically an application of Newton’s laws with a dash of clever feedback control – by altering stiffness or applying counter-forces, the isolator ensures that the supported object sees as little motion as possible.

Another technique involves active force cancellation. This is analogous to noise-cancelling headphones, but for vibrations: the system senses the disturbance and an actuator (say a piezoelectric stack or a voice-coil motor) generates an equal-and-opposite force to nullify the vibration. Active vibration tables for laboratories use this method – they constantly monitor table motion and use actuators at the legs to cancel out floor vibrations. These require advanced control algorithms to react in real time (often using PID controllers or more advanced control theory like H∞ optimization mdpi.com), but they can achieve impressive isolation even at very low frequencies where passive mounts would normally struggle.

Some adaptive isolators achieve their effect by tuning damping rather than (or in addition to) stiffness. For instance, magnetorheological (MR) fluids and elastomers are materials that change viscosity or elasticity when exposed to a magnetic field. An MR-based vibration isolator can thus behave like a shock absorber that gets “stiffer” or “softer” in terms of damping at the flip of an electric current. These have been used in everything from car suspensions to building isolators. A magnetorheological elastomer mount can be designed such that applying a magnetic field significantly raises its stiffness, giving a controllable spring that the system can stiffen or loosen as needed continental-industry.com. Similarly, shape-memory alloys (metals that change stiffness with temperature) and piezoelectric actuators (which change length under voltage) have been explored to create mounts that adapt on command numberanalytics.com. While the engineering details differ, the unifying idea is that the isolator is no longer static. It becomes a dynamic system with a feedback loop: sense the vibration, decide on a response, and adjust the isolator accordingly – all within fractions of a second.

To put it in a more accessible image: imagine walking on a suspension bridge that sways with the wind. A traditional isolator is like a fixed damper on the cables – good for a specific wind speed, but if the wind changes, it might sway too much or too little. A dynamic adaptive isolator is more like a smart system that feels the bridge motion and instantly tightens or loosens the cables, or even moves a counterweight, to steady the sway no matter the wind gusts. In fact, nature gave us inspiration here: our own bodies have adaptive vibration control. When you run on a hard surface, your muscles and tendons stiffen; when you walk gently, they relax. This biological strategy of sensing, processing, and responding is explicitly serving as a model for engineered systems nature.com. Researchers have mimicked the way the human nervous system quickly adjusts muscle stiffness to isolate our body from shocks, implementing similar “reflexes” in vibration isolators via sensors and microcontrollers nature.com. The result: an isolator that behaves less like a static cushion and more like a living, reactive system – constantly balancing and adjusting to keep vibrations at bay.

State-of-the-Art Technologies in Adaptive Isolation

The field of vibration isolation has seen a surge of innovation as engineers strive to achieve better adaptability. Current state-of-the-art technologies can be broadly grouped into a few categories:

- Advanced Passive Isolators (High-Static-Low-Dynamic Stiffness and Quasi-Zero-Stiffness): These are passive designs that cleverly overcome some limitations of linear springs. HSLDS isolators use mechanisms (like pre-buckled beams or magnetic negative-stiffness elements) to create a situation where the system is very stiff for static loads but very soft for dynamic motions. Quasi-zero-stiffness isolators go even further – through special geometric or magnetic arrangements, they exhibit an effective stiffness near zero over a range of motion, which means they have an extremely low natural frequency mdpi.com. This allows excellent isolation of low-frequency vibrations while still supporting weight. For example, some optical tables use mechanical linkages or air springs adjusted to achieve quasi-zero stiffness. However, these passive solutions still have fixed settings once built. They represent the pinnacle of non-adjustable design – great within their intended band, but not adaptive beyond that. Researchers are also exploring metamaterials and lattice structures (like origami patterns) to realize negative or zero stiffness in compact forms. A recent review highlighted how magnetic negative-stiffness (MNS) devices can attain near-zero stiffness and significantly expand the isolation bandwidth without sacrificing load capacity mdpi.com. These MNS-based isolators – using configurations of magnets and springs – have shown transformative potential for low-frequency isolation, especially when combined with other techniques mdpi.com.

- Active Vibration Isolation Systems: These are the high-tech champs that use powered actuators to directly cancel vibrations. They often involve an arrangement of voice coil motors, piezoelectric stacks, or hydraulic actuators supporting the payload. With continuous sensor feedback, they apply forces that oppose and negate incoming vibrations. Active isolators can achieve isolation starting at very low frequencies (even below 1 Hz), which is far beyond what most passive mounts can do. For instance, active vibration isolation tables for electron microscopes or gravitational wave detectors use sophisticated control to float the instrument as if it were in free space. One active system described in the literature uses H∞ optimal control to minimize vibrations transmitted from a base to sensitive equipment, dynamically adjusting forces to counteract disturbances mdpi.com. Because active systems can adapt in real time, they handle variable and unpredictable vibrations extremely well. The trade-off is that they require power and careful control tuning (and they can be expensive). Nonetheless, they are state-of-the-art for protecting ultra-precision instruments. It’s not just lab equipment – active isolation is used in spacecraft (to isolate delicate satellite components) and even proposed in building foundations. The ability to continuously sense and counteract vibrations makes active isolators essentially adaptive by design. Modern controllers are so fast and robust that some active isolators even tackle multi-axis vibrations simultaneously, using platforms that actuate in 6 degrees of freedom (imagine a high-tech motion platform that instead of shaking you in a theme park, does the opposite by keeping you perfectly still!).

- Semi-Active and Smart Material-Based Isolators: Falling between passive and active, semi-active isolators don’t inject energy via large actuators but can modulate their internal properties. A prime example is the magnetorheological (MR) isolator. These devices use MR fluids or elastomers whose stiffness/damping can be instantly varied by magnetic fields. They effectively act as tunable dampers or springs. For instance, an MR elastomer-based vibration isolator was recently designed with an adjustable stiffness range – its core is a special rubber that becomes much stiffer when magnetized, allowing the isolator to switch between a soft and stiff state as needed bohrium.com. Because MR technology responds in milliseconds, such isolators can adapt nearly in real time, without the complexity of moving parts. Semi-active systems also include things like adaptive hydraulic mounts (with valves that open/close to change damping) and pneumatic isolators with adaptive orifices. One commercial example is adaptive engine mounts in some vehicles, which use electronic valves or even ER/MR fluids to change their damping characteristics on the fly continental-industry.com. Continental AG recently highlighted that their adaptive engine mounts incorporate mechatronic components to match the mount stiffness to engine conditions, including frequency-selective stiffness switching and on-demand damping adjustment continental-industry.com. These mounts can, for example, go soft at idle (to absorb engine shake) and then firm up during driving for stability – effectively two mounts in one continental-industry.com. Semi-active isolators are popular because they offer much of the adaptability of active systems but with simpler hardware and typically fail-safe behavior (since they can only dissipate energy, not inject it – they won’t go unstable).

- Hybrid Systems: Some of the most cutting-edge work combines passive and active elements to get the best of both. For instance, an active-HSLDS isolator was demonstrated where a traditional negative-stiffness (HSLDS) spring was augmented with piezoelectric actuators and a control loop link.springer.com. This hybrid could broaden the isolation bandwidth and cut the resonant peak dramatically compared to the passive version link.springer.com. Essentially, the passive HSLDS provided a low baseline stiffness, and the active control fine-tuned the response around resonance, achieving up to ~90% vibration reduction in tests link.springer.com. Hybrids might also use passive isolators for primary load support and active actuators in parallel to “trim” the motion. These approaches are state-of-the-art in applications where reliability and performance are both paramount (for example, a passive element carries the load if power fails, while active control is available during operation). Academic research often points to hybrid isolation as a promising direction, since it leverages passive stability plus active adaptability mdpi.com. We also see hybrid thinking in multi-stage isolators (e.g., a coarse passive stage plus a fine active stage). All these innovations reflect a vibrant, multidisciplinary effort – drawing on mechanical engineering, materials science, and control electronics – to achieve vibration isolation that is both high-performing and adaptive.

Recent Innovations and Research Highlights (as of 2025)

The past couple of years have yielded remarkable breakthroughs in dynamic vibration isolation. Researchers are actively pushing the envelope to create isolators that are smarter, more efficient, and applicable to new challenges. Here are a few highlights of recent innovations:

- Bio-Inspired “Full-Spectrum” Adaptive Isolation (2025): One of the most talked-about developments is an intelligently excitation-adaptive vibration isolation (IEA-VI) system reported in 2025 nature.com. This system was directly inspired by human reflexes and the way our body adjusts to shocks nature.com. The engineers at Harbin Institute of Technology (China) designed a mechatronic isolator that only has two modes – a low-stiffness mode (high-static-low-dynamic-stiffness, like a soft suspension) and a high-stiffness mode – but it can switch between them in real time based on the vibration input nature.com. It uses a nesting electromagnetic actuator alongside a spring, plus a smart controller that detects the dominant vibration frequency via fast Fourier transform (FFT) and model-based algorithms nature.com. The moment it senses a low-frequency disturbance that would normally cause resonance, it flips to the stiff mode to avoid excessive motion, and vice versa. In experiments, this bio-inspired system achieved “full-spectrum” vibration control, meaning it protected the payload across low and high frequencies without the usual resonant spike nature.com. Essentially, it mitigated the resonance issues that even advanced passive isolators like QZS suffer from, by being clever about when to be soft and when to be stiff nature.com. The result is a major step toward an isolator that adapts as deftly as a human balance system, heralded as a solution to the long-standing bandwidth vs. load-capacity dilemma in vibration isolation nature.com. This innovation underscores how integrating real-time sensing and actuation can overcome the fundamental limits of passive designs.

- Origami-Based Adaptive Isolator (2023): In late 2023, researchers at KAIST in South Korea unveiled a novel vibration isolator that takes a very different approach – it changes shape! The device is based on a thin-walled Yoshimura-pattern origami tube that can reconfigure its geometry to tune its stiffness pure.kaist.ac.kr. By deploying or retracting the origami modules (using embedded actuators, such as shape-memory alloys), the isolator’s force-transmission characteristics alter. Multiple such reconfigurable modules were combined, and the team demonstrated that by systematically changing the origami pattern configuration, they could adjust the isolator’s transmissibility to suit different vibration environments pure.kaist.ac.kr. In other words, one physical device could be “morphed” to perform optimally for different frequency contents or load conditions. They built a prototype and validated experimentally that the concept works – the prototype showed clear changes in vibration isolation performance corresponding to the shape changes, confirming the adaptive characteristics of this origami isolator pure.kaist.ac.kr. This innovation is exciting because it merges principles of mechanical metamaterials (origami structures) with adaptive control. It’s easy to imagine future isolators that could literally fold or unfold to adapt – a very futuristic idea of a shape-shifting vibration damper!

- Active Negative-Stiffness Hybrid (2024): We touched on hybrids earlier; in 2024, a team published results for an active HSLDS vibration isolator that combines the best of passive and active worlds link.springer.com. They took a conventional buckling-beam isolator (which has the desirable high-static-low-dynamic stiffness trait) and added piezoelectric actuators with a feedback controller to it link.springer.com. The active control extends the negative stiffness “stroke” of the buckling beams – effectively keeping the system in the sweet spot of low dynamic stiffness over a larger range of motion link.springer.com. In tests, compared to a traditional HSLDS isolator, the active version broadened the isolation bandwidth and drastically reduced the resonant peak amplitude link.springer.com. Impressively, the active hybrid could shift the resonant frequency from about 31 Hz down to ~13 Hz by dynamically adjusting forces, achieving nearly 90% vibration reduction at peak link.springer.com. This means vibrations that would normally cause a big spike in response were almost entirely suppressed. Such results are significant for industries like automotive or machinery where adding a small active component can dramatically improve an existing passive mount’s performance. It showcases a practical path to retrofitting or upgrading isolation systems – you don’t have to reinvent the entire mount, just add a smart actuator to an already good design and gain adaptive capabilities.

- Magnetorheological and Fluidic Innovations: Researchers continue to refine MR-based isolators as well. In 2024 and 2025, various studies reported new designs of magnetorheological elastomer (MRE) isolators with adjustable stiffness bohrium.com and even hybrid MR fluid QZS systems. One 2025 report described a compact isolator integrating MR fluid dampers with a quasi-zero-stiffness spring, achieving highly stable low-frequency isolation that can be actively tuned by the magnetic field sciencedirect.com. The adaptability of MR isolators is particularly attractive for vehicular and civil engineering applications, where conditions (like payload mass or excitation frequency) can change and a controlled stiffness/damping device can accommodate those changes. We’re also seeing electrohydraulic mounts (with on/off valves) and pneumatic isolators with active valves emerging in recent research as simpler adaptive solutions. For instance, an adaptive pneumatic vibration isolation platform was prototyped that adjusts its air-spring pressure via solenoid valves in response to disturbances, significantly improving isolation when activated (according to a 2024 conference report pmc.ncbi.nlm.nih.gov). Each of these innovations might target different niches – e.g. vehicles, building foundations, precision lab equipment – but all share the theme of actively tuning mechanical properties to fight vibrations. The steady progress in materials (like better MR fluids), sensors, and faster control electronics (allowing higher feedback bandwidth) is making these semi-active approaches ever more viable.

- Bio-Inspired Mass Adjustment and Metamaterials: The creativity in this field is remarkable. Not only are engineers mimicking the human body’s adaptive stiffness, some are looking at animal kingdom tricks. For example, one study in 2024 proposed a “frog-inspired” adaptive-mass QZS isolator – essentially a seat suspension that imitates how a frog can adjust its leg posture (mass distribution) when landing to absorb shock researchgate.net. By dynamically shifting an attached mass, the system could maintain a quasi-zero stiffness condition even as load changes, offering stable low-frequency isolation under varying conditions. In a similar vein, a spider-inspired isolator was designed using a curved beam and linear spring mimicking a spider foot, yielding a QZS effect for low-frequency vibration isolation in a lightweight structure pubs-en.cstam.org.cn. These bio-inspired designs are at early stages, but they hint at future isolators that might reconfigure not just stiffness but also mass or geometry in real time – a holistic adaptivity. Additionally, metamaterials (engineered materials with periodic microstructures) are being tailored for vibration control. There has been work on metamaterial isolators that create bandgaps (frequency ranges of very high isolation) and can even be tuned post-fabrication. For instance, researchers have demonstrated a metamaterial with tunable negative-stiffness elements that achieve extremely low-frequency vibration bandgaps by adjusting the configuration of internal beams mdpi.com. While much of this is still in the lab or prototype stage, it shows the frontier of adaptive vibration isolation involves clever use of geometry and materials, not only traditional actuators.

In summary, as of 2025, dynamic adaptive vibration isolators are an area of rapid advancement. Papers and prototypes are appearing that make what once was sci-fi (like a mount that automatically retunes itself mid-operation) into reality. Whether by copying nature’s tricks, using magnetic fluids, origami engineering, or hybrid smart systems, researchers are continually expanding the toolkit for fighting unwanted vibrations. The trend is clearly toward isolators that are more autonomous, versatile, and integrated – often combining multiple techniques (passive + active + smart materials) to get the best overall performance. It’s an exciting time for this field, as these innovations start moving from the lab into real-world applications.

Applications Across Industries

Adaptive vibration isolators have compelling applications in a variety of industries. Virtually anywhere vibration is a problem – be it tiny micro-vibrations that blur a microscope or large shocks that stress a structure – these isolators can make a difference. Here’s how they’re being applied across different fields:

Aerospace and Aeronautics

In aerospace, both the journey and the destination involve harsh vibrations. During rocket launches, satellites and sensitive payloads experience intense vibration and shock. Once in orbit, however, certain equipment (like telescopes or microgravity experiments) require an ultra-stable, vibration-free environment. Dynamic isolators are tackling both problems. Space agencies have employed active and passive adaptive isolators to protect delicate instruments. For instance, NASA’s Jet Propulsion Laboratory (JPL) has used advanced vibration isolators for testing telescope optics. “For optics that operate in roughly visible wavelengths, any motion on the scale of one micron…disturbs the image quality,” explained one JPL instrument engineer, underscoring why isolators are critical azonano.com. JPL collaborated with a US company, Minus K Technology, to develop special passive isolators with negative-stiffness for the James Webb Space Telescope (JWST) testing chamber – six huge isolators that could each support 10,000 lbs, the largest of their kind azonano.com. These provided a stable, cushioned platform that filtered out ground vibrations even in a vacuum environment.

For ground testing of satellites and spacecraft components, adaptive suspension platforms are used to simulate microgravity by actively canceling out gravitational forces and vibrations mdpi.com. An emerging solution here is electromagnetic levitation isolators, which use magnetic fields to float a payload without contact. Because they are frictionless and work in vacuum, they’re ideal for space hardware testing mdpi.com. Research suggests such levitation-based adaptive isolators can provide six-degree-of-freedom support and vibration filtering for large precision payloads, addressing a need as space instruments grow in size and sensitivity mdpi.com. In spacecraft on orbit, active vibration isolation platforms have been used to protect microgravity experiments on the International Space Station (ISS) – e.g. equipment like sensitive combustion experiment modules are mounted on active isolation racks that counteract vibrations from astronaut activity or machinery. These systems often employ adaptive feedback control to isolate to micro-g levels. The aerospace industry is also investigating adaptive base isolators for flight vehicles: imagine mounting an aircraft’s avionic bay on adaptive absorbers to counteract engine vibrations, or using adaptive seat isolators to protect astronauts and pilots from sustained g-load vibrations. Given the extreme and varying conditions of aerospace, adaptive isolators are becoming key enabling technology for missions that demand high precision and resilience. As one industry review noted, even minute vibrations can affect spacecraft performance (such as a satellite’s imaging or a military drone’s sensors), so vibration control “has become a cornerstone for modern high-tech” aerospace platforms daeilsys.com.

Automotive and Transportation

The automotive world has long dealt with vibration issues (known in auto engineering as NVH – Noise, Vibration, and Harshness). What’s new is the rise of smart mounts and suspension components that adapt to driving conditions. Many luxury and performance cars now feature adaptive suspensions – these use electronically controlled shock absorbers (often filled with magnetorheological fluid or with adjustable valves) to continuously vary damping. Hitting a pothole at speed? The system stiffens up to prevent bottoming out. Cruising on a smooth road? It softens for comfort. The result is better ride comfort and handling stability. Similarly, adaptive engine mounts are increasingly used to isolate engine vibrations. Continental AG, for instance, produces adaptive hydromounts that have switchable stiffness and damping continental-industry.com. At idle, an engine can cause a low-frequency shake – the adaptive mount opens a valve or engages a softer fluid path to absorb this, reducing cabin rumble. Under heavy acceleration or at higher RPMs, that same mount can firm up (closing the fluid bypass or activating an electromagnetic damper) so that the engine is held steady, improving vehicle response and preventing excessive movement continental-industry.com. These mounts “optimize the vibration behavior, especially at idling… and ensure good handling in dynamic driving,” by tailoring their characteristics to the driving situation continental-industry.com. Essentially, they solve the age-old conflict between a soft, comfy mount (good for idle vibration isolation) and a stiff mount (good for control during driving) by being both, depending on need continental-industry.com.

Beyond cars, adaptive vibration control is used in rail and shipping. High-speed trains, for example, use semi-active dampers between cars that adjust in curves vs. straight paths to reduce vibration and sway. Aircraft utilize adaptive vibration absorbers in the fuselage to counteract engine buzz or aerodynamic vibrations – Boeing and others have experimented with active vibration control units to make cabins quieter. Even helicopter rotors, which induce a lot of vibration, have seen research on adaptive rotor head dampers that adjust to different flight regimes. The transportation sector benefits from adaptive isolators by achieving both comfort and structural longevity. By reducing vibration, they not only make the ride nicer, they also prevent long-term fatigue damage to vehicle components. With the push toward electric vehicles (EVs), new challenges like very quiet drivetrains (meaning other vibrations like road noise become more noticeable) and battery protection are arising – adaptive isolation and damping systems are poised to play a role in solving these. For instance, EVs might employ active motor mounts that cancel out the subtle high-frequency vibrations from electric motors or to isolate heavy battery packs from road shocks. The trend is clear: our vehicles are getting “smarter” suspensions and mounts that adapt hundreds of times per second, all in the name of a smoother, safer ride.

Manufacturing and Precision Electronics

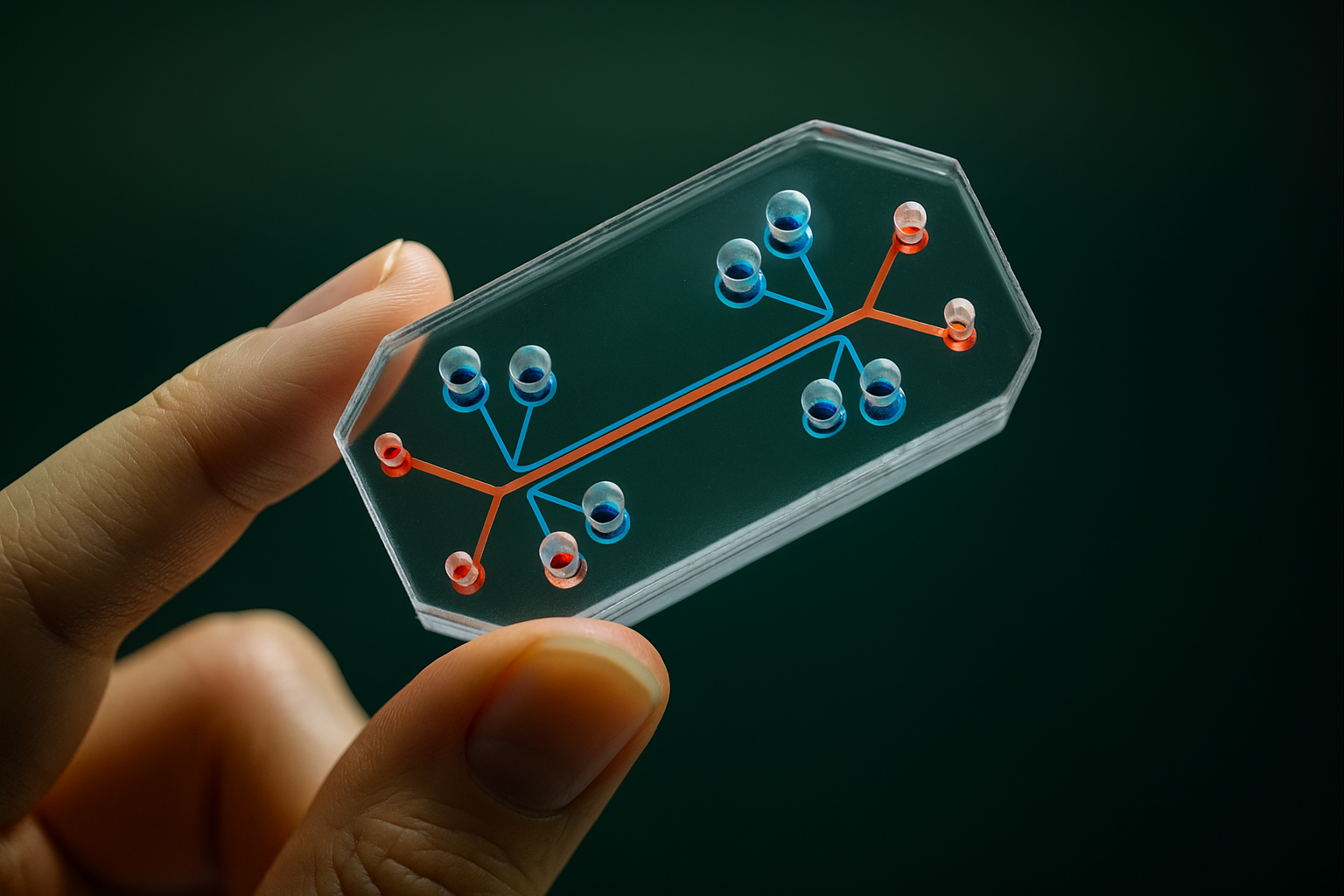

Modern manufacturing, especially in semiconductors, optics, and nanotechnology, demands an extremely quiet vibration environment. Machines like photolithography steppers, electron microscopes, and laser interferometers can be disrupted by even tiny tremors – a passing truck outside or an AC unit turning on can introduce enough vibration to blur a 5-nanometer circuit pattern or throw off a delicate measurement. Here, dynamic vibration isolators are the unsung heroes enabling progress. For instance, semiconductor fabrication equipment often sits on active vibration isolation platforms. These use air springs combined with active feedback control or voice-coil actuators to isolate the tool from floor vibrations. As precision requirements have increased, passive air springs alone weren’t enough; now systems actively sense table motion in all six degrees of freedom and counteract it. A telling example: in photolithography (used to make computer chips), the stages that move silicon wafers and masks must hold alignment to nanometer accuracy while moving quickly. This is only possible because their support systems provide both gravitational support and vibration isolation with advanced control mdpi.com. Vibration isolation in such tools is so critical that it directly impacts chip yields and quality daeilsys.com. Manufacturers have reported that implementing vibration control early in a production line (to stabilize machines) improves throughput and reduces defect rates, which in turn boosts profitabilitydaeilsys.com.

In scientific research and electronics labs, optical tables and microscope platforms now routinely feature adaptive isolation. An ultra-high magnification microscope might sit on a table that actively cancels out building vibrations; without it, the image would drift or blur. Companies offer tabletop active isolators (some based on piezoelectric actuators) that kick in at very low frequencies (starting around 1 Hz or below) seismion.com. The benefit is dramatic – what used to require building a heavy concrete slab in a quiet basement can now be achieved with a smart compact platform. Even consumer electronics manufacturing benefits: factories that assemble things like hard drives or MEMS sensors use vibration-isolated assembly stations to avoid tiny misalignments. And in the realm of precision 3D printing or lithography, adaptive isolation ensures that the only movements are the ones intentionally commanded by the machine, not external interference.

A particularly challenging setting is when precision machines must operate in a vacuum environment (common for semiconductor tools and space instrument testing). Traditional isolators that rely on air (pneumatic isolators) or contain rubbers can be problematic in vacuum due to outgassing or lack of air for damping azonano.com. Adaptive isolator technology is addressing this by introducing designs that work in vacuum – such as vacuum-compatible active electromagnetic isolators (with all electronics and actuation inside the vacuum chamber). The Minus K passive negative-stiffness isolators mentioned earlier are a hit in such scenarios because they use no air or power, thus “they are happy as can be in a vacuum”, to quote a JPL engineering director azonano.com. For even greater adaptability, researchers consider combining these passive supports with active fine-tuning that also functions in vacuum (using piezo actuators that don’t outgas). The upshot is that precision manufacturing and research absolutely rely on adaptive vibration isolation to push the limits. Whether it’s making a semiconductor chip with billions of tiny features or imaging an atom through a microscope, dynamic isolators ensure that the only movements are the ones we want. As one industry publication pointed out, mastering these invisible vibrations is essentially mastering a form of silent competitive advantage in tech industries daeilsys.com – the companies and labs that implement superior vibration control can achieve higher precision and throughput than those that don’t.

Other Notable Applications (From High-Tech to Everyday)

Adaptive vibration isolation even finds uses in places you might not expect. High-end audio is one niche example. Audiophile turntables and speakers can be sensitive to vibration (footfalls, equipment hum, etc.), which affects sound quality. Companies like Seismion in Germany have developed active vibration isolator platforms for audio equipment – their Reactio series actively isolates hi-fi components, and the latest version can start isolating at frequencies as low as 1 Hz, greatly reducing even the slightest background vibrations seismion.com. They advertise this to passionate audiophiles who “strive for the perfect reproduction of their music” seismion.com. It might sound overkill, but in the quest for perfect sound, removing vibration from turntables or tube amplifiers can indeed prevent audio distortion and feedback. This shows how adaptive isolation tech is trickling into luxury consumer applications.

In the field of civil engineering, adaptive damping and isolation is an emerging area. While most building base isolators are passive (e.g., rubber bearings or friction pendulums for earthquake protection), there is research on semi-active base isolation where the damping can be adjusted in real time during an earthquake to optimize energy dissipation. Large magnetorheological dampers have been tested in bridges and buildings, allowing the structure to react differently depending on the quake intensity link.springer.com. For example, Japan has experimented with active mass dampers on skyscrapers (giant weights at the top, actively controlled to counter building sway). These can be seen as large-scale vibration isolators protecting the structure from wind or seismic vibrations. As algorithms improve, the hope is to have “smart buildings” that autonomously adjust their isolation/damping settings for optimal resilience.

Even in biomechanics and healthcare, adaptive vibration control has roles: isolation of MRI machines (to get sharper imaging by canceling building vibrations), protecting sensitive laboratory incubators or nanoscale 3D printers, and even vibration-cancelling platforms for people (for instance, to reduce vibrations for surgeons doing microsurgery, or for workers operating delicate tasks). Active anti-vibration gloves and tool mounts exist to cancel tool-induced vibration for workers (reducing fatigue and injury). These are essentially personal-scale active isolators. We also see adaptive mounts in appliances (a washing machine with an active vibration cancellation system to eliminate spin-cycle shaking, for instance, has been prototyped).

The broad adoption of dynamic adaptive vibration isolators across industries—from NASA’s space labs to car factories to audio studios—underlines their versatility. Whenever there’s something that needs to be very still or protected from shake, an adaptive isolator can provide a tailored calm in an otherwise shaky world. And as the technology matures and costs come down, we’re likely to see it in even more everyday places, quietly doing its job (pun intended) to make our devices and environments more stable.

Key Players and Innovators in Adaptive Isolation

This interdisciplinary field has attracted contributions from both academic research labs and specialized companies around the world:

- Research Labs and Universities: Many breakthroughs originate in universities. The Harbin Institute of Technology (HIT) in China is a leader, with its School of Astronautics producing the 2025 IEA-VI full-spectrum isolator and numerous papers on active and nonlinear isolation nature.com. In South Korea, KAIST’s adaptive structures lab has pioneered origami-based isolators and smart materials for vibration control pure.kaist.ac.kr. Institutions like MIT and Caltech (often in conjunction with JPL) have contributed to active vibration isolation for space and optics. University of Bristol and Imperial College London have strong groups in nonlinear vibration isolators and metamaterials. In Australia, groups at The University of Adelaide and Monash University have worked on adaptive automotive mounts and magnetorheological systems. Chinese universities (beyond HIT, like Southeast University, Zhejiang University, etc.) have produced prolific research on quasi-zero-stiffness isolators and electromagnetic hybrids mdpi.com. There’s also significant work in Japan (e.g., University of Tokyo on space isolators) and Germany (e.g., TU Munich on active mount systems). Collaboration across mechanical engineering, materials science, and control engineering departments is common to tackle the multi-faceted challenges of adaptive isolation.

- Industry and Companies: Several companies specialize in vibration isolation and have been integrating adaptive features. Minus K Technology (USA) is famous for its passive negative-stiffness isolators (used by NASA for JWST and by labs worldwide azonano.com), and while their core products are passive, they are often used in hybrid setups with active control. Newport / MKS and TMC (Technical Manufacturing Corp.) are known for optical table isolators; they offer active vibration isolation tables and platforms used in research labs and semiconductor fabs. Herzan (part of Spicer Consulting) and Accurion produce active vibration cancellation systems for microscopes and precision instruments. Bilz and ETS Lindgren in Germany supply industrial vibration isolation and have products with active leveling and damping control (for example, active air springs). Stabilus (a major manufacturer of automotive and industrial dampers) has been exploring active and semi-active mounts, and LORD Corporation (now part of Parker Hannifin) was a pioneer in magnetorheological automotive mounts and continues to develop MR-based isolation for vehicles and machinery. Continental is another big player in automotive adaptive mounts, as highlighted by their production-ready switchable engine mounts continental-industry.com.

In specialized niches, Seismion (Germany) focuses on high-end audio and scientific active isolators seismion.com. Daeil Systems (South Korea) provides active and passive vibration control solutions for semiconductor and display industries, emphasizing tailored systems for different precision equipment daeilsys.com. Mitsubishi Heavy Industries and other large conglomerates have units working on seismic adaptive dampers for buildings. And on the aerospace/defense side, companies like Airbus and Lockheed Martin have in-house developments or collaborations for isolating satellite components and sensitive payloads (for instance, Lockheed’s work on a vibration isolation system for space optical benches, and Airbus’s active helicopter seat dampers).

It’s worth noting that often the cutting-edge systems arise from collaborations – for example, a university lab develops a concept and then a company helps turn it into a product, or an aerospace agency funds a new isolator design that later becomes commercially available. As of 2025, the ecosystem of dynamic adaptive isolation tech is a healthy mix of academic innovation and industrial implementation. And with market research indicating robust growth in active vibration control solutions (the desktop active isolation market alone was estimated around $250 million in 2024 archivemarketresearch.com), more players are likely to enter the field. The competition and collaboration ensure that these technologies will keep advancing and find broader use.

Challenges and Future Outlook

While dynamic adaptive vibration isolators are making great strides, there are still challenges to overcome and exciting opportunities on the horizon.

Key Challenges:

- Complexity and Cost: Adding sensors, actuators, and controllers inevitably makes an isolator more complex and costly than a simple passive rubber mount. For industries like consumer electronics or general machinery, cost is a barrier to adoption. The systems also require power (for active types) and maintenance of more components. Reducing the complexity – for instance, developing simpler adaptive mechanisms or more integrated electronics – will be crucial to wider use. There’s active research into simplifying control algorithms and using cost-effective components (like leveraging cheap MEMS accelerometers and microcontrollers as they become ubiquitous).

- Reliability and Fail-safe Behavior: In critical applications, an adaptive isolator must fail gracefully. If an active system loses power or a sensor fails, it shouldn’t make things worse (for example, you wouldn’t want a car’s adaptive suspension to suddenly go rock-hard or flaccid in a dangerous way). Designing hybrid systems with passive backup, or smart failsafe modes, is an engineering challenge. Additionally, long-term durability of actuators (like piezo stacks can crack, MR fluids can settle or leak) needs attention. Ensuring that the fancy new isolator can survive harsh environments (heat, vacuum, dust) over years is non-trivial. For instance, early active isolators using hydraulics had issues with valve wear and fluid contamination over time, which had to be mitigated.

- Control and Stability: Tuning a feedback control loop for an active isolator can be tricky. If not done right, an active isolator can become unstable (oscillating on its own). We want these systems to automatically adjust to different conditions – essentially a form of adaptive control. Techniques like self-tuning or adaptive algorithms (which adjust control parameters on the fly) are being explored sciencedirect.com, but adding adaptability in control increases risk of instability. Future systems might incorporate machine learning or AI to optimize control settings for complex, multi-frequency environments – some preliminary work is looking at ML to predict and cancel vibrations – but that’s still nascent. Right now, a lot of engineering goes into ensuring the controller of an active isolator is robust to various scenarios (for example, using disturbance observers and robust control schemes in automotive active engine mounts sciencedirect.com). Continued improvements in control theory and sensing will be needed to make these systems truly “plug and play” adaptive without manual tuning.

- Multi-Degree-of-Freedom and Broadband Performance: Real-world vibrations are rarely in one direction or at one frequency – they are multi-axis and broadband. Designing isolators that can adapt in 3D or 6D (6 degrees of freedom) is challenging. Some active platforms achieve this, but they’re expensive and bulky. The future calls for more compact multi-axis adaptive isolators, possibly using novel arrangements of smart materials. Additionally, extremely low-frequency vibrations (below ~0.5 Hz, like building sway or very slow seismic drift) remain hard to isolate – active systems can chase them, but sensors also drift at those scales. On the high-frequency end, beyond a certain point, isolators hand off to other solutions (like material damping or acoustic insulation). Bridging these gaps – effectively covering the full frequency spectrum – is an ongoing challenge. The 2025 bio-inspired study explicitly aimed at “full-spectrum” coverage nature.com, highlighting this demand. Future designs may incorporate multiple modes of control (e.g., an isolator that is active at low frequencies and passive-damping at high frequencies) to tackle this.

- Integration and Space Constraints: In many applications, space and weight are at a premium (think aerospace or handheld devices). Adaptive isolators can be heavier or bulkier due to extra components. There’s a push to develop integrated designs where the sensing and actuation are built into the structure itself (for example, embedding piezoelectric layers in the mount that both sense and actuate). Materials research is looking at structural materials that can change properties (like variable modulus materials) to possibly eliminate separate actuators. The ideal would be an isolator that is no larger than a passive one but with all the adaptive functionality embedded. Achieving that integration is a future goal.

Despite these challenges, the outlook for dynamic adaptive vibration isolators is bright. Several trends point toward their increased importance:

- Ever-Increasing Precision Requirements: As technology advances, whether it’s manufacturing smaller nanostructures or launching larger telescopes, the tolerance for vibration gets tighter. Traditional solutions won’t suffice, so adaptive isolators become not just nice-to-have but necessary. For example, one review notes that with rising precision demands in manufacturing, electromagnetic levitation isolation (a high-tech solution) “is imperative” for the next generation of ultra-precision equipment mdpi.com. We can expect that future fields like quantum computing, holographic displays, or advanced medical imaging will all require pristine vibration environments – fueling demand for innovative isolation.

- Advancements in Materials and Electronics: The continued development of smart materials (better MR fluids, electroactive polymers, etc.) and cheap, powerful electronics (sensors and microcontrollers) will make adaptive isolators more affordable and reliable. The price of an accelerometer or DSP controller today is a fraction of what it was a decade ago, and this trend lowers the cost barrier. Also, actuators like piezos are improving (e.g. new alloys for greater strain) and even exotic options like optical or electrostatic actuators could find use for ultra-clean, vacuum-friendly isolation. With materials like graphene and carbon nanotubes being explored for damping and springs, we might see lighter and stronger isolator components too.

- Cross-Pollination with Other Technologies: Adaptive vibration control might benefit from advances in related domains. For instance, the rise of active noise control (for sound) and active aerodynamics in vehicles shows that feedback control is increasingly used in traditionally passive areas. As more engineers become comfortable with designing “smart” systems, we’ll see more creative implementations. Perhaps drones will have adaptive isolators for their cameras to get ultra-stable footage, or consumer electronics (like smartphones) might include micro-scale vibration isolation for enhanced camera stabilization beyond what OIS (optical image stabilization) does. There’s also interesting research in using energy harvesting in tandem with vibration isolation – imagine an isolator that not only adapts but also siphons off vibration energy and converts it to electricity to power itself. A few studies have looked at combining vibration isolation with energy harvesting so the isolator is self-powered, which could be transformative for remote or battery-powered applications.

- Wider Adoption and Standardization: As the technology proves itself, it tends to become standard. Active suspension in cars was once exotic (found only in Formula 1 or luxury sedans), but semi-active suspensions are now present in quite a few mid-range vehicles. We can foresee adaptive engine mounts becoming common in electric vehicles to deal with the different vibration profile of electric motors. In aerospace, any future space telescope will almost certainly incorporate adaptive isolation for its instruments – it’s just too risky otherwise when you need ultra-fine pointing stability. On factory floors, as older equipment is replaced, it’s likely that integrated active isolation will become a standard feature of high-end machine tools and measuring instruments. Market trends already show growth in these products archivemarketresearch.com, and competition will likely drive costs down and adoption up.

Looking further ahead, one can imagine intelligent vibration networks – where sensors all over a facility or vehicle communicate and preemptively adjust isolators in a coordinated way. For example, a smart building might detect an incoming vibration (say, from nearby construction) and dynamically tune all its isolation systems (from foundation isolators to equipment mounts) to counter it in real time. This kind of holistic, IoT-enabled vibration control could be a future development once individual adaptive isolators are widely in place.

In conclusion, dynamic adaptive vibration isolators represent a significant leap in our ability to protect structures and equipment from unwanted motion. They bring a level of agility and intelligence to vibration control that was not possible with older methods. As one review aptly put it, we are seeing the “transformative potential” of these technologies in redefining what’s achievable in vibration isolation mdpi.com. Challenges remain in making them simpler and more widespread, but the pace of innovation is high. These isolators are quietly (and literally!) making our world more stable – enabling sharper images from space telescopes, faster and finer manufacturing, longer-lasting machines, and even sweeter music from our speakers. The quiet revolution in vibration isolation is well underway, and it’s poised to keep industries humming smoothly into the future.

Sources:

- Zhu & Chai (2024), Applied Sciences – Magnetic Negative Stiffness Devices for Vibration Isolation: Review mdpi.com

- Yan et al. (2022), Applied Math. and Mechanics – Review on Low-Frequency Nonlinear Isolation (Electromagnetic QZS) link.springer.com

- Li et al. (2025), Communications Engineering (Nature) – “Intelligent excitation adaptability for full-spectrum real-time vibration isolation” nature.com

- Suh & Han (2023), J. Intelligent Material Sys. – Origami-Based Adaptive Vibration Isolator pure.kaist.ac.kr

- Xu et al. (2024), Applied Math. and Mechanics – Active HSLDS Vibration Isolator with Piezoelectric Control link.springer.com

- Yu et al. (2025), Journal of Sound and Vibration – MRE-Based Vibration Isolator with Adjustable Stiffness bohrium.com

- Continental AG – Adaptive Engine Mounts Product Page continental-industry.comc

- DAEIL Systems (2025) – Industry Perspective on Vibration Control daeilsys.com

- Seismion GmbH (2023) – Reactio Plus Active Vibration Isolator Announcement seismion.com

- AZoNano (2019) – How Vibration Isolators Help Telescope Optics (JPL interview) azonano.com

- (Additional citations within text from sources [1], [33], [40], [43] as numbered above)