Imagine batteries made from common aluminum foil and sulfur powder, powering everything from homes to electric cars at a fraction of today’s costs. Aluminum- and sulfur-based batteries are emerging as promising alternatives to traditional lithium-ion cells, offering the tantalizing potential of cheaper, safer, and more sustainable energy storage. In this report, we delve into what these aluminum and sulfur batteries are, how they work, the different types under development (including an exciting combo of aluminum and sulfur), their advantages and challenges, the key players driving breakthroughs, and how recent innovations in 2024–2025 could transform clean energy and electric vehicles. (All sources are cited for credibility.)

What Are Aluminum and Sulfur Batteries?

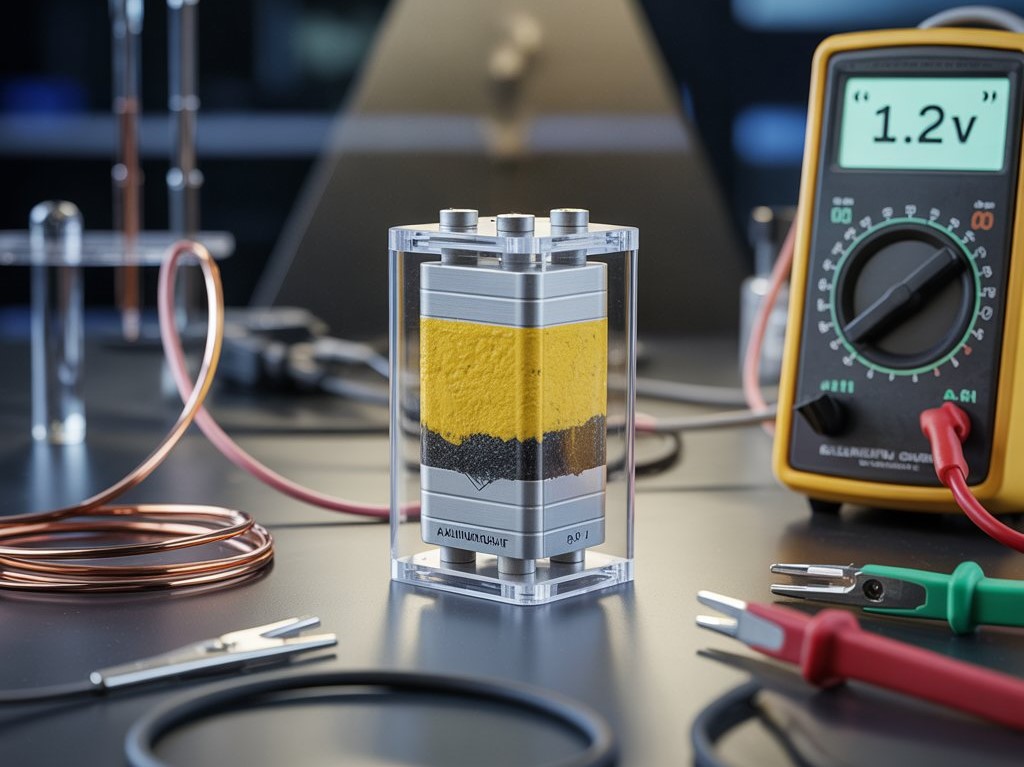

Aluminum batteries and sulfur batteries represent two broad families of next-generation rechargeable battery technologies that aim to address the limitations of today’s lithium-ion batteries. Simply put, they use aluminum or sulfur (or both) in their electrochemical reactions instead of relying solely on lithium-based chemistries. Just like any battery, these have three main parts – a positive electrode (cathode), a negative electrode (anode), and an electrolyte in between that shuttles ions during charging and discharging. The key difference is the chemistry: in aluminum batteries, the metal aluminum often serves as the anode (and in some designs provides the charge-carrying ions), whereas in sulfur batteries, the element sulfur typically serves as the cathode material accepting ions from a metal anode (like lithium or sodium).

Why explore aluminum or sulfur? Both elements are incredibly abundant and inexpensive compared to lithium and cobalt used in Li-ion cells. Aluminum is the most abundant metal in Earth’s crust and has a very high theoretical capacity for storing charge (each Al atom can release 3 electrons, giving it a charge capacity of 2.98 Ah per gram, which is enormous) nature.com. Sulfur is one of the cheapest non-metal elements (often a byproduct of petroleum refining) and can bind with two lithium ions per atom, enabling very high energy storage potential nature.com, anl.gov. In principle, batteries using aluminum or sulfur could hold more energy for a given weight and cost a lot less than today’s lithium-ion packs. As researchers at Argonne National Laboratory explain, “Sulfur is extremely abundant and cost effective and can hold more energy than traditional ion-based batteries.” anl.gov Likewise, aluminum is cheap, widely available, and stores charge densely both by weight and volumenature.com.

Another big motivator is safety and sustainability. Lithium-ion batteries use flammable organic liquid electrolytes and often require scarce metals (like cobalt, nickel, lithium) that raise supply chain and ethical issues. In contrast, many aluminum and sulfur battery designs can use non-flammable electrolytes (such as ionic liquids or molten salts) and avoid conflict minerals. For example, a recent lithium-sulfur battery design uses only “abundantly available local materials, eliminating the need for mined minerals like nickel, cobalt, manganese, and graphite,” according to battery startup Lyten lyten.com. MIT Professor Donald Sadoway – a leading battery innovator – has been explicitly searching for “cheap, Earth-abundant” ingredients to invent something “much better than lithium-ion”, settling on aluminum for the anode and sulfur for the cathode in his latest battery chemistry news.mit.edu.

In short, aluminum and sulfur batteries are an attempt to build a cheaper, safer, and more ethical battery by using elements that are plentiful (no global supply squeeze), inexpensive, and inherently high-capacity. Now let’s explore how these batteries work in practice and the different types under development.

How Do They Work? (Battery Basics in Plain Language)

Aluminum-based batteries typically use aluminum metal as the anode. When the battery discharges, the aluminum metal gives up electrons (producing an electric current) and aluminum ions (Al³⁺) that travel through the electrolyte to the cathode. Depending on the battery type, those aluminum ions either intercalate (insert) into a cathode material or react with it. For example, in an aluminum-ion battery, Al³⁺ ions shuttle into a layered cathode (like graphite or a metal oxide) and back out during charging news.stanford.edu. In an aluminum-sulfur battery, the aluminum ions react with sulfur at the cathode to form aluminum-sulfur compounds during discharge, and then return to aluminum metal when charging nature.com. And in aluminum-air batteries, aluminum metal reacts with oxygen from the air at a special cathode, producing aluminum oxide or hydroxide – a reaction that releases electricity until the aluminum anode is consumed.

Sulfur-based batteries usually involve a sulfur cathode paired with a metal anode (lithium is most common, but sodium and even magnesium or aluminum can be used). Taking lithium-sulfur (Li-S) as an example: when discharging, lithium metal atoms at the anode give up electrons and become lithium ions (Li⁺) that travel through the electrolyte to the sulfur cathode. The sulfur (S₈ molecules) there gets converted into lithium sulfide (Li₂S) by incorporating lithium ions – essentially sulfur soaks up lithium ions and electrons to form new compounds, storing energy in the chemical bonds. During charging, this process reverses: the lithium ions leave the sulfur and return to the anode, and sulfur is regenerated. Because each sulfur atom can bind two lithium atoms, and S₈ rings can break into various lithium polysulfide molecules, Li-S batteries can in theory store 3–5 times more energy per weight than Li-ion. Sodium-sulfur (Na-S) batteries work analogously with sodium ions and typically form sodium polysulfides or sodium sulfide.

In all these batteries, ions shuttle back and forth through an electrolyte while electrons flow through an external circuit – that’s how the battery charges and discharges. The electrolyte can be a liquid, gel, or solid that allows the ions to move but forces electrons to go through the circuit (which powers your device). Importantly, some of these new chemistries require special electrolytes to function. Aluminum-ion batteries often rely on ionic liquid or molten salt electrolytes because Al³⁺ ions strongly interact with typical solvents. In fact, early rechargeable aluminum batteries only became viable when researchers found a room-temperature ionic liquid (based on chloroaluminate salts) that lets aluminum ions slip in and out of a graphite cathode efficiently news.stanford.edu. Similarly, lithium-sulfur batteries often use modified liquid electrolytes or solid electrolytes to prevent issues we’ll discuss later (like sulfur leaking into the electrolyte).

To summarize in simple terms: aluminum batteries generate power by the aluminum metal giving off multiple electrons per atom (incredibly high charge per metal atom) and forming bonds either with a host cathode or with oxygen/sulfur, while sulfur batteries generate power by having a light, abundant element (sulfur) capture metal ions and electrons into energy-rich compounds. Both designs move us beyond the single-lithium-ion transfer of current batteries, potentially packing more punch per charge. Next, let’s look at the specific varieties of these batteries under development.

Types of Aluminum-Based Batteries

Researchers are exploring several types of batteries that use aluminum in different ways:

- Rechargeable Aluminum-Ion Batteries (Al-Ion): These batteries use aluminum metal as the anode and typically a graphitic cathode with a special ionic liquid electrolyte. A famous early example came from Stanford University in 2015, where scientists demonstrated a prototype aluminum-ion battery with an aluminum anode and a graphite cathode in an ionic liquid. It showed ultra-fast charging (a small cell could be charged in about one minute!) and extremely long cycle life (over 7,500 charge cycles with no capacity loss) news.stanford.edu. The Stanford cell was also very safe – researchers could drill through the pouch cell without it catching fire, unlike lithium cells news.stanford.edu. However, it had a lower voltage (~2 volts, roughly half a typical Li-ion cell’s voltage) news.stanford.edu, meaning more cells would be needed in series to reach useful voltages. Key appeal: Al-ion batteries promise fast charging, long life, and improved safety (no fire-prone components), using cheap materials (aluminum and carbon) news.stanford.edu. Ongoing research aims to boost their energy density by finding better cathodes and electrolytes to increase voltage and capacity news.stanford.edu. Several groups worldwide (from Stanford to Chinese universities news.mit.edu) are advancing aluminum-ion tech. For instance, researchers are investigating various cathode materials (even including metal sulfides nature.com) to store aluminum ions more effectively nature.com.

- Aluminum-Air Batteries: Aluminum-air is a primary battery (non-rechargeable by electricity, but potentially mechanically “refueled”) where aluminum metal reacts with oxygen from air to generate electricity. These cells have an impressively high energy density because the cathode is just ambient air – making the battery extremely lightweight. In fact, aluminum-air packs can have about 3 times the energy per weight of lithium-ion at the system level evreporter.com. The trade-off is that once the aluminum anode oxidizes into aluminum hydroxide or oxide, the cell is “spent” and needs fresh aluminum to continue. This makes aluminum-air more like a fuel cell or a range extender: you’d swap in a new aluminum plate (and recycle the used one) rather than plug it in to charge. Companies like Phinergy in Israel have been pioneering aluminum-air systems for years. In partnership with Indian Oil Corporation, they are piloting aluminum-air batteries in electric vehicles and stationary backup units. In 2023, they demonstrated a small electric car in India that drove over 500 km on aluminum-air cells before needing an aluminum “refuel”evreporter.com. Phinergy’s CEO David Mayer notes that aluminum-air tech is “safe, non-flammable,” requires no heavy charging infrastructure, and can be recharged (by replacing aluminum) “in a few minutes” instead of hours evreporter.com. The downside is establishing a whole supply chain to mass-produce and recycle aluminum plates. Yet, this tech is already commercial in niches: e.g. Phinergy’s aluminum-air units are deployed as backup power for telecom towers (replacing diesel generators) in Israel and Europe evreporter.com. Aluminum-air batteries might not directly replace the rechargeable battery in your phone, but they could serve as range extenders for EVs or long-duration storage – providing a huge energy reserve that you swap out periodically.

- Aluminum-Sulfur Batteries: Fascinatingly, some researchers are combining aluminum and sulfur in one battery – using aluminum as the anode and sulfur as the cathode, with a molten salt or ionic liquid electrolyte. This hybrid approach tries to harness the best of both elements: aluminum’s high anode capacity and sulfur’s high cathode capacity, all with incredibly cheap materials. In August 2022, a team led by MIT’s Donald Sadoway unveiled a new aluminum-sulfur battery design that immediately grabbed headlines for its low cost and performance. It uses molten chloro-aluminate salts as the electrolyte, which operate at a modest temperature (around 110 °C, similar to a hot cup of coffee) to keep the salt liquid news.mit.edu. The heated electrolyte was a clever choice: not only is it non-flammable and inexpensive, it also prevented dendrites – those pesky metal spikes that can short-circuit batteries. As Sadoway put it, the chosen salt “essentially retired these runaway dendrites, while also allowing for very rapid charging” news.mit.edu. His aluminum-sulfur prototype cell could be charged in less than a minute without shorting, and ran for hundreds of cycles with an estimated cost per cell about one-sixth that of comparable lithium-ion cells news.mit.edu. This is a huge cost reduction, confirmed by outside analysts; material costs for these batteries could be 85% lower than lithium-ion according to Science magazine news.mit.edu. The vision is to use such cells for stationary storage (e.g. storing solar energy for night-time use) and possibly for EV fast-charging support. Sadoway’s design is being commercialized by a startup called Avanti, which aims to scale up the cells and perform stress tests in the near future news.mit.edu. Meanwhile, other groups are pushing the aluminum-sulfur concept further: in January 2024, researchers in China reported a rechargeable Al-S battery that can run at 85 °C (just below water’s boiling point, even easier to maintain) with excellent life – over 1,400 cycles with only 15% capacity loss, and the ability to fast-charge at that temperature nature.com. Lowering the operating temperature below 100 °C means simple hot-water heating could maintain the battery, which “greatly simplifies” thermal management and opens the door to broader applications nature.com. Bottom line: Aluminum-sulfur batteries could become a game-changer for grid storage and perhaps certain vehicles, by delivering ultra-low-cost, fire-resistant batteries that use Earth-abundant aluminum (the most abundant metal) and sulfur (the cheapest non-metal) news.mit.edu.

Types of Sulfur-Based Batteries

Several battery technologies leverage sulfur cathodes paired with different anodes:

- Lithium-Sulfur (Li-S) Batteries: Lithium-sulfur is one of the most studied “post-lithium” chemistries because of its sky-high energy potential. A Li-S cell can theoretically store up to 5x the energy per weight of a lithium-ion cell, since sulfur is so lightweight and each sulfur can bind multiple lithium atoms. In practice, Li-S batteries have already demonstrated energy densities around 400–500 Wh/kg (roughly double that of Li-ion) in labs businessaviation.aero, apricum-group.com. They are also attractive for being very cheap and green – sulfur costs almost nothing and is abundant, and Li-S cells contain no cobalt or nickel. However, the Achilles’ heel of Li-S has been longevity and stability. Traditional Li-S prototypes suffered from the “polysulfide shuttle” effect: intermediate sulfur compounds (polysulfides) dissolve into the electrolyte during cycling and migrate to the lithium anode, causing self-discharge, corrosion, and rapid capacity fade anl.gov. They also undergo significant “breathing” (volume changes) – sulfur expands and contracts a lot as it charges/discharges, which can damage the cell structure reuters.com. These issues meant early Li-S batteries died after just tens of cycles. The good news is that recent breakthroughs are resolving these problems. Researchers have developed nano-structured carbon cathodes and electrolytes additives to trap polysulfides and extend lifespan nature.com. In January 2023, Argonne National Lab demonstrated a Li-S cell with a special porous “redox-active” interlayer that nearly eliminated the shuttle problem, allowing the battery to endure 700+ cycles while maintaining high capacity anl.gov. “Previous [sulfur] batteries only suppressed the shuttling but sacrificed energy. Our layer adds storage capacity and suppresses shuttle,” explained Argonne chemist Guiliang Xu anl.gov. This suggests Li-S batteries can be made both high-energy and long-lived. In fact, companies are now racing to commercialize them: Lyten, a California startup, has developed a lithium-sulfur cell reinforced with proprietary 3D graphene materials and is targeting niche markets like drones, aerospace and defense in 2024–2025 lyten.com. Lyten claims its Li-S batteries are 40% lighter than today’s lithium-ion (and 60% lighter than iron-phosphate batteries) while being cheaper at scale due to the elimination of nickel, cobalt, and other costly materials lyten.com. Another company, Theion (Germany), is working on crystalline sulfur cathodes and recently reported Li-S cells with 3× the energy density of Li-ion, at only one-third the cost, and potentially one-third the production emissions reuters.com. Theion’s CEO Ulrich Ehmes said their batteries – which avoid the corrosion issues by using a stable form of sulfur and a pre-expanded design – could be in electric vehicles “before the end of the decade” if development stays on track reuters.com. In short, lithium-sulfur batteries are on the cusp of graduating from lab to market, promising ultra-light, high-energy packs for applications where every kilogram counts (electric aircraft, long-range EVs, space).

- Sodium-Sulfur (Na-S) Batteries: Sodium and sulfur might sound like an unlikely pair (sodium is extremely reactive, and early Na-S batteries ran hot at 300°C), but this chemistry has a long pedigree for grid storage. High-temperature Na-S batteries have been used in utility-scale energy storage for decades (notably by NGK in Japan) – they operate with molten sodium and sulfur separated by a solid ceramic electrolyte, delivering good efficiency and longevity for stationary storage. However, the need to keep them at ~300 °C limited wider adoption. Recently, there’s excitement about room-temperature sodium-sulfur batteries that could offer a low-cost, safe alternative for large-scale storage. In late 2022, a team at the University of Sydney announced a “low-cost battery with four times the capacity of lithium-ion” using a new room-temperature Na-S design sydney.edu.au. By using a porous carbon electrode and a simple thermal treatment (pyrolysis) to create a more reactive form of sulfur, they achieved super-high capacity and ultra-long life at room temperature, overcoming Na-S’s previous “sluggish” performance sydney.edu.au. Lead researcher Dr. Shenlong Zhao said this sodium-sulfur battery “has the potential to dramatically reduce costs while providing four times as much storage capacity. This is a significant breakthrough for renewable energy development…” sydney.edu.au. Indeed, sodium and sulfur are even more abundant and cheap than lithium, so a successful Na-S battery could be a boon for grid energy storage – enabling big batteries for wind/solar farms with minimal cost. While Na-S cells don’t match Li-ion for compact EV needs (sodium is heavier, and these cells are currently larger format), they could become a critical piece of the clean energy infrastructure, offering safe and low-cost storage for when the sun isn’t shining or the wind isn’t blowing sydney.edu.au. Research is ongoing worldwide (China, Australia, Europe) to refine room-temperature Na-S batteries for commercialization.

- Other Sulfur-Based Batteries: Beyond Li-S and Na-S, researchers have experimented with sulfur cathodes in combination with other metals like magnesium or calcium, and even pairing sulfur with aluminum (as discussed earlier). These multivalent metal–sulfur batteries (where the metal ion carries more than one charge, e.g. Al³⁺ or Mg²⁺) are appealing for the same reason as aluminum or sulfur alone – abundance and high capacity – but they face even trickier chemistry and are mostly in early research stages advanced.onlinelibrary.wiley.com. For instance, magnesium-sulfur cells struggle with electrolyte compatibility and sluggish kinetics. Solid-state sulfur batteries are another cutting-edge variation: by using a solid electrolyte (often a sulfide or polymer), scientists aim to make Li-S cells that are safer (no flammable liquid) and that suppress the polysulfide shuttle entirely onlinelibrary.wiley.com, businessaviation.aero. NASA has been actively developing a solid-state lithium-sulfur battery (project SABERS) using a sulfur-selenium cathode and a novel solid electrolyte, reaching energy densities ~500 Wh/kg suitable for electric aviation businessaviation.aero. The allure of sulfur – light, abundant, powerful – has placed it at the center of many futuristic battery concepts.

Having covered the landscape of aluminum and sulfur battery types, we can now compare how these technologies stack up against the reigning lithium-ion and what unique benefits they offer.

Key Benefits and Advantages Over Lithium-Ion

Both aluminum-based and sulfur-based batteries promise significant advantages in cost, sustainability, and performance if their development continues successfully. Here are the key benefits:

- 🌎 Abundant, Low-Cost Materials: Aluminum and sulfur are cheap and plentiful virtually everywhere. Aluminum is the most abundant metal in the earth’s crust, and sulfur is a common byproduct of refining. This means material costs can be drastically lower. A report by Science noted that the raw materials for an aluminum-sulfur battery could be 85% cheaper than those for lithium-ion batteries news.mit.edu. Theion (a sulfur battery startup) similarly claims their cells will cost only one-third as much as Li-ion cells reuters.com. In Sadoway’s words, these batteries are “ethically sourced, cheap, [and] effective” news.mit.edu – they avoid expensive metals that are often tied to problematic mining. Using abundant resources also means fewer supply bottlenecks; we won’t face lithium or cobalt shortages if aluminum and sulfur batteries take off.

- 🔥 Improved Safety (Non-Flammable): Many next-gen aluminum/sulfur batteries are designed to be far safer. Instead of flammable organic electrolytes, they may use inorganic molten salts or solid electrolytes that do not ignite news.mit.edu. Aluminum-ion and aluminum-sulfur cells demonstrated by Stanford and MIT “won’t catch fire, even if you drill through [them]” or operate at high temperature news.stanford.edu, news.mit.edu. Likewise, sulfur cathodes paired with solid or gel electrolytes can resist thermal runaway better than conventional Li-ion. Phinergy’s aluminum-air system is inherently non-combustible and “safe, non-flammable” in operation evreporter.com. Increased safety not only protects users, but also simplifies transportation and manufacturing (no need for costly cooling or fire suppression in battery packs).

- ⚡ High Energy Density & Lightweight: Both chemistries offer the potential for higher energy storage per weight than today’s batteries. Lithium-sulfur batteries, for example, have achieved ~500 Wh/kg in prototypes businessaviation.aero – about double the best Li-ion, enabling much lighter battery packs. Lyten reports its Li-S cells will be up to 40% lighter than Li-ion packs for the same energy lyten.com. Theion targets 3x the energy density of Li-ion reuters.com. For electric vehicles and aircraft, this could translate to longer range or higher payload for the same battery weight. Aluminum-air is off the charts in energy density (it was used to set a record 1,100-mile EV drive on a single aluminum-air “tank” a few years back), albeit with refueling needed. Even aluminum-ion batteries, though lower in theoretical energy than Li-S, can excel in power density – Stanford’s cell could fully charge in one minute news.stanford.edu, hinting at batteries that recharge as quickly as filling a gas tank. In short, these technologies could deliver either much more energy (for long-duration use) or much faster discharge/charge rates than Li-ion, or both.

- 🔋 Long Cycle Life Potential: Properly engineered, aluminum and sulfur batteries could last as long or longer than Li-ion. Aluminum metal anodes don’t form the same kind of dendrites as lithium (especially under the right electrolytes) news.mit.edu, so they can be very durable. The Stanford Al-ion cell survived 7,500+ cycles (an order of magnitude beyond Li-ion) news.stanford.edu. Sulfur cells historically had poor cycle life, but new designs (interlayers, solid-state, etc.) are achieving hundreds or thousands of cycles with minimal loss anl.gov, nature.com. For stationary storage, a battery that reliably cycles every day for 10+ years is crucial, and developers of these chemistries are keenly focused on stability.

- ♻️ Environmental & Ethical Benefits: Because they use readily available materials, these batteries avoid the environmental damage associated with mining and processing scarce metals like cobalt, nickel, and lithium. There’s also a reduction in the embedded carbon footprint of the battery. Theion estimates their sulfur battery cells will emit only one-third the CO₂ in production compared to Li-ion cells reuters.com. Sulfur is often a waste product (millions of tons sit in stockpiles), so using it in batteries is essentially recycling industrial waste. Aluminum is highly recyclable as well – an existing global recycling infrastructure could be leveraged to recover aluminum from spent batteries easily. Ethically, using sulfur and aluminum sidesteps the child labor and human rights issues that have plagued cobalt mining. All these factors mean next-gen batteries could be more sustainable and socially responsible across their lifecycle.

- 💡 Fast-Charging and High Power: Some aluminum/sulfur designs are demonstrating ultra-fast charging capability. We’ve mentioned the 60-second charging in lab tests news.stanford.edu. Additionally, aluminum-sulfur cells in the lab have operated at very high charge rates (e.g. charging at 1C or above at elevated temp with excellent retention) nature.com. Aluminum-air can be “recharged” instantly by swapping aluminum. These features could alleviate one of the biggest consumer complaints with EVs and gadgets – long charging times – and also provide high power output when needed (imagine power tools or EVs with aluminum batteries that deliver a strong punch without voltage sag).

It’s important to note that not every one of these benefits applies equally to all variants (for instance, aluminum-air gives great energy but isn’t electrically rechargeable; aluminum-ion charges fast but has lower voltage; Li-S is super light but currently has moderate cycle life). However, the overall promise of aluminum and sulfur batteries is that we can dramatically lower costs and reliance on rare materials while delivering equal or better performance in key areas of safety, energy, and power.

Challenges and Technical Hurdles

If aluminum and sulfur batteries are so great, why aren’t they everywhere yet? The truth is, these technologies face significant challenges that researchers and engineers are still working to overcome:

- Polysulfide Shuttle and Cathode Degradation (Sulfur Issues): In lithium-sulfur and other sulfur cathode batteries, the notorious polysulfide shuttle problem has been a showstopper. As the battery cycles, sulfur goes through intermediate stages that can dissolve into the electrolyte and wander to the anode, causing self-discharge, loss of active material, and even damaging reactions with the anode anl.gov. This leads to rapid capacity fade. Moreover, sulfur cathodes tend to swell and contract significantly (up to ~80% volume change) as they convert to lithium sulfide and back reuters.com. This “breathing” can pulverize the cathode over time or delaminate it from current collectors. Although new strategies (like adding protective interlayers anl.gov, using nano-structured carbon hosts, or solid electrolytes) have mitigated these issues, ensuring a sulfur battery can last hundreds of cycles in real-world conditions remains a key challenge.

- Dendrites and Plating Issues (Metal Anodes): Aluminum metal anodes, like other metal anodes, can form dendrites (thin, conductive filaments) when recharging, which risk short-circuiting the cell. In fact, a major reason aluminum batteries long failed was that no one could get the plating/stripping of aluminum to repeat reliably – it would often form a “mossy” deposit or deactivate by forming a surface oxide. The ionic liquid and molten salt electrolytes have gone a long way to “tame” this issue (with one team reporting their molten-salt Al battery “never lost cells due to dendrite shorting” in fast-charge tests news.mit.edu). But if a more conventional electrolyte were used, dendrites or side reactions with aluminum’s oxide coating could be problematic. Similarly, if lithium metal is used as the anode in sulfur batteries (common in Li-S designs), lithium dendrites and safety issues arise, especially if using liquid electrolytes. Researchers often pair Li-S with protective membranes or solid-state designs to prevent lithium dendrites.

- Low Operating Voltage and Energy Efficiency (Aluminum Ion): Aluminum-ion batteries, particularly those using intercalation (e.g. graphite cathodes), typically have a lower cell voltage than Li-ion. Stanford’s famous aluminum-ion cell produced about 2.0 volts news.stanford.edu, whereas a lithium-ion cell is ~3.7 V nominal. This is partly due to the chemistry of Al³⁺ intercalation and the electrolyte constraints. Lower voltage means you need more cells in series (adding complexity and some energy loss) to reach a desired battery pack voltage. There’s also the issue of multivalent ions like Al³⁺ having sluggish kinetics in solids – moving a +3 charged ion is harder than a +1 ion like Li⁺, so achieving high power can be tough unless the temperature is raised or special electrolytes are used nature.com. Some Al batteries only operate well at elevated temperatures (60–100 °C) which could complicate their usage in consumer electronics (nobody wants a constantly hot battery in their phone!). The good news: innovations in electrolytes (like adding certain salts or using new mixtures) are improving aluminum-ion conductivity at lower temperatures nature.com.

- Temperature Requirements: As noted, several aluminum and sodium based designs use molten salt electrolytes that need to be kept warm. For instance, the MIT aluminum-sulfur battery runs optimally at about 110 °C news.mit.edu, and even the improved variant runs at 85 °C nature.com. While these aren’t red-hot by industrial standards, it means a battery pack would need insulation and maybe a small heater to stay in the right range. This is fine for stationary storage (where a fridge-sized battery can have thermal management) but is a challenge for portable applications and EVs unless the heat can be self-sustaining (Sadoway’s cell actually self-heats during cycling to maintain temperature news.mit.edu). High-temperature operation also demands robust sealing and safety considerations (though the upside is no fire risk). Researchers are working to bring operating temps down and even exploring room-temperature chemistries for both Al and Na based systems nature.com.

- Charging Infrastructure and “Refueling” (Al-Air): Unique to aluminum-air (and similar metal-air systems) is the issue that they aren’t rechargeable by plugging into a charger. You need to replace or recycle the aluminum anode once it’s used up. This requires creating an entire infrastructure for swapping aluminum plates or cartridges, collecting the spent ones, and recycling aluminum (probably through a smelting process powered by electricity, effectively “recharging” the aluminum). Indian Oil and Phinergy are actively working on this ecosystem evreporter.com, but it’s a different paradigm from gas stations or charging stations. Without widespread support, aluminum-air might remain niche. Additionally, the byproduct of aluminum-air (aluminum hydroxide) needs to be dealt with – though it can be recycled into new aluminum or other products.

- Manufacturing Scale-Up and Integration: Lithium-ion technology has a 30-year head start with massive manufacturing scale, optimized supply chains, and a well-trained workforce. Any new battery chemistry faces the hurdle of moving from lab bench or pilot scale to gigafactory scale. Aluminum and sulfur batteries may require new manufacturing processes (for example, handling moisture-sensitive ionic liquids or solid electrolytes, or new cell designs like Theion’s stacked electrodes). Scaling up without defects and at low cost is non-trivial. There’s also the issue of integration – can these new batteries drop into existing devices or vehicles, or do they need new designs? Different voltage profiles, form factors, or operating conditions might mean retooling everything from battery management systems to chassis design in cars. These transitional costs and uncertainties can slow adoption.

- Current Status (Technology Readiness): While 2024 and 2025 have seen big breakthroughs (as we’ll highlight next), many aluminum and sulfur battery technologies are still in the prototype or early commercial stage. None have yet seen the kind of mass deployment that lithium-ion enjoys. For example, lithium-sulfur cells are just now entering limited markets like drones and satellites, where their short lifespan can be tolerated or mitigated. Aluminum-sulfur and aluminum-ion are in the demonstrator and scale-up phase; no electric car or grid has a large one in full service yet. This means there’s still the risk of unforeseen issues cropping up in real-world use (think of how Li-ion faced incidents with thermal runaway early on). It will take time, investment, and likely a few iterations before these technologies are as reliable as the incumbent. As one skeptical note: lithium-ion gets better every year too – with new chemistries like lithium-iron-phosphate (LFP) and lithium-metal solid-state on the horizon – so aluminum and sulfur batteries must not only work, but compete against an improving incumbent.

In summary, aluminum and sulfur batteries hold huge promise but also present unique hurdles. Researchers are candid that more work is needed; as one team wrote in 2022, despite progress, “Al–S batteries have suffered poor rate capability and cycling stability” historically, requiring continued innovation in electrolytes and electrodes nature.com. Overcoming these challenges is exactly what many labs and startups are focused on right now.

Who’s Leading the Charge? Major Players in Development

This exciting field has a mix of academic labs, startups, and industry giants pushing the envelope. Here are some of the notable players and what they’re doing:

- Massachusetts Institute of Technology (MIT) & Avanti: MIT has been a hotbed for innovative battery research. Professor Donald Sadoway’s group at MIT spearheaded the aluminum-sulfur battery concept. After publishing the breakthrough results in Nature in 2022, Sadoway co-founded Avanti to commercialize the technology news.mit.edu. Avanti’s goal is to scale up production of aluminum-sulfur cells for stationary storage and beyond. Sadoway is famous for having also co-founded Ambri, a company commercializing liquid metal batteries (using different chemistries like calcium and antimony). Ambri is targeting grid-scale storage and was reported to be deploying systems in 2024 youtube.com. Between Ambri and Avanti, Sadoway’s innovations could cover large utility batteries down to smaller-scale batteries for buildings or EV charging stations news.mit.edu. MIT’s influence doesn’t stop there – its researchers are also exploring lithium-sulfur in projects, and the institute often partners with national labs and companies on cutting-edge battery tech.

- Stanford University & SLAC: Stanford made early waves in aluminum-ion batteries (the 2015 fast-charging Al-ion prototype news.stanford.edu). That work, led by Prof. Hongjie Dai, showed that a simple graphite cathode could enable a rechargeable aluminum battery. Stanford continues to do battery research; for instance, SLAC (the Stanford Linear Accelerator Lab) has studied novel cathodes for aluminum batteries like metal sulfides nature.com, and investigated interfacial chemistry to improve cycling. While Stanford’s 2015 discovery hasn’t yet turned into a commercial product, it demonstrated feasibility and has been cited by many subsequent studies. It also underlined Stanford’s ethos of open research leading to industry adoption (some Stanford battery alumni have joined startups or formed their own in the Bay Area’s battery startup scene).

- Graphene Manufacturing Group (GMG) & University of Queensland: In Australia, GMG (in collaboration with University of Queensland) has been developing a Graphene Aluminum-Ion Battery. They have reported impressive performance in coin-cell prototypes – with extremely fast charging and long cycle life – using graphene (a form of carbon) as a cathode material in an aluminum-ion configuration batteriesnews.com. GMG has been aiming to scale their tech to pouch cells suitable for consumer electronics or EVs, and as of late 2022 they had a development program and pilot production line in the works graphenemg.com. Their approach underscores the synergy of nano-materials (graphene) with new chemistries like aluminum-ion to get better results.

- Phinergy and Indian Oil (IOC): Phinergy is an Israeli startup that has been a pioneer in aluminum-air batteries for over a decade. They famously powered a demo car for 1,100 miles using aluminum-air in 2014, and have since focused on real products for backup power and EV range extension. Phinergy partnered with Indian Oil Corporation to form a joint venture (IOC Phinergy) that is bringing aluminum-air technology to India’s market – potentially huge for a country eager to find oil alternatives and utilize its aluminum industry. By early 2023, IOC Phinergy showcased India’s first aluminum-air powered vehicle and was setting up infrastructure for plate manufacturing and recycling alcircle.com. The Indian government has shown interest as well, as aluminum-air could reduce dependence on imported lithium. Phinergy’s tech is already commercially used in telecom tower backups (replacing diesel generators with emission-free aluminum-air systems) evreporter.com, and they are working with automakers like Mahindra on vehicle integration (e.g. test fleets of electric rickshaws and buses using aluminum-air for extended range) evreporter.com. Phinergy’s progress is crucial because it’s one of the first to take an aluminum-based battery out of the lab and into practical field deployments.

- Lyten: Lyten is a Silicon Valley startup (based in San Jose, California) that has been in stealth mode for several years developing a Lithium-Sulfur battery enhanced with a proprietary 3D graphene material. They recently emerged with big news: in October 2024, Lyten announced plans to build the world’s first lithium-sulfur battery gigafactory in Nevada, with a $1+ billion investment lyten.coml. The facility is slated to produce 10 GWh of Li-S batteries annually by 2027 lyten.com. This bold move indicates confidence that their technology is near readiness for mass production. Lyten’s initial target markets are not passenger EVs but micromobility, aerospace, drones, and defense in 2024–2025 lyten.com – areas where the high energy density of Li-S offers a decisive advantage and where slightly lower cycle life may be acceptable. The company emphasizes its batteries’ light weight and lack of conflict minerals, and indeed their cells use lithium metal anodes and sulfur-carbon composite cathodes, avoiding nickel, cobalt, etc. lyten.com. Lyten’s CEO, Dan Cook, said “Lithium-sulfur is a leap in battery technology, delivering a high energy density, light weight battery built with abundantly available local materials” lyten.com. They have even manufactured pilot battery cells in-house since 2023 to test and refine the production process lyten.com. If Lyten’s gigafactory succeeds, it could be a game-changer – the first commercial Li-S batteries made at scale, potentially for use in next-gen electric aircraft or long-range electric semi-trucks where every pound matters.

- Theion: Theion is a Berlin, Germany-based startup focusing on lithium-sulfur batteries with a twist – they use crystalline sulfur and special electrodes to improve stability. In March 2025, Theion raised €15 million in a Series A funding round to scale up their battery cells reuters.com. Theion claims its cells can triple the energy density of lithium-ion while cutting costs to one-third, as mentioned earlier reuters.com. They have reportedly solved key issues by pre-expanding the cathode to accommodate sulfur’s expansion and by keeping sulfur in a crystalline form that is less reactive with electrolytes reuters.com. CEO Ulrich Ehmes has stated their technology could find use in EVs, “flying taxis,” or energy storage, and potentially be in cars by late 2020s reuters.com. Theion’s approach has attracted attention because it doesn’t rely on exotic materials – they tout that their batteries “breathe” less and don’t corrode like earlier Li-S. The funding will help them develop larger pouch cells and move beyond coin-cell prototypes reuters.com. Germany’s interest in sulfur batteries also aligns with Europe’s drive to have home-grown, sustainable battery technologies.

- Argonne National Laboratory & U.S. DOE: In the public research sphere, Argonne (along with other U.S. Department of Energy labs like Oak Ridge and Pacific Northwest) has been actively researching sulfur batteries. We discussed Argonne’s achievement in interlayer design for Li-S cells anl.gov. They are also exploring solid-state sulfur batteries in partnership with NASA for aviation. The DOE’s Vehicle Technologies Office has funded multiple projects on Li-S, Mg-S, and even Li-Air and Al-Air, recognizing the strategic importance of next-gen chemistries. National labs often collaborate with universities (e.g., Argonne worked with a team including the University of Illinois on sulfur interlayers) and share findings that startups can build upon. For example, much of the understanding of polysulfide behavior and advanced characterization (using tools like Argonne’s Advanced Photon Source for X-ray analysis of batteries anl.gov) comes from these labs.

- Other Notables: Universities like Monash University (Australia) made headlines in 2020 with a Li-S battery that could purportedly power a smartphone for five days and showed excellent stability via a novel binder and electrode design advancedsciencenews.com. Monash has since worked on fast-charging Li-S as well, aiming for electric aviation uses monash.edu. In the UK, the now-defunct Oxis Energy was a pioneer in Li-S; before its closure in 2021, Oxis had developed Li-S cells nearing 400 Wh/kg and was working with airplane manufacturers. Its IP was acquired by other entities, possibly informing new projects. Chinese academia and industry are extremely active – institutions like the Chinese Academy of Sciences, Wuhan University of Technology (which co-authored Sadoway’s Al-S paper news.mit.edu), and companies like CATL are exploring sulfur and aluminum chemistries, though details are sometimes kept under wraps. Even Tesla’s Battery Day in 2020 hinted at interest in sulfur (Elon Musk quipped about Tesla researching “lithium and sulfur” without elaboration, possibly for long-term projects). Lastly, NASA and Boeing are looking at Li-S for aircraft: NASA’s SABERS project has a multi-layered sulfur battery that hit 500 Wh/kg, which could enable electric airplanes or advanced drones businessaviation.aero.

It’s clear that a global ecosystem of innovators is pushing aluminum and sulfur batteries forward – from scrappy startups to venerable national labs. The next few years (2025–2030) will likely see some of these efforts bear fruit in the form of real products and pilot deployments.

Breakthroughs and Recent Innovations (2024–2025)

The period of 2024 into 2025 has been particularly exciting for aluminum and sulfur battery developments, with several noteworthy breakthroughs:

- Jan 2024 – Aluminum-Sulfur at 85 °C (Nature Communications): Researchers demonstrated a new aluminium–sulfur battery that operates at 85 °C with a quaternary molten salt electrolyte, published in Nature Communications nature.com. This battery showed rapid-charging capability and surprising longevity: it retained 85.4% of its capacity after 1,400 cycles at 1C charge rate nature.com. Importantly, 85 °C is a big improvement over earlier molten-salt batteries that needed 110–180 °C nature.com. The team achieved this by formulating a special mix of salts (alkali chloroaluminates) with a low melting point, which also facilitated fast aluminum-ion movement nature.com. They also used a nitrogen-doped porous carbon cathode that helped the sulfur reactions proceed quickly nature.com. This result is significant because it points toward practical, low-cost grid batteries that could operate with simple heating (even just hot water as a heat source, as the authors note nature.com) and deliver fast charging without degradation. It’s a step toward making the MIT Al-S battery concept more user-friendly and mobile.

- Oct 2024 – Lyten Announces Li-S Gigafactory: Lyten’s announcement of a lithium-sulfur battery gigafactory in Nevada was a major industry headline in late 2024 lyten.com. It’s slated to be the world’s first gigafactory dedicated to Li-S cells, targeting 10 GWh/year production by 2027 lyten.com. Even more striking was Lyten stating that its Li-S batteries are already entering select markets in 2024 and 2025 – specifically, they have customers in micromobility (e-bikes, scooters), aerospace (maybe satellites or high-altitude drones), drones, and defense applications using their batteries lyten.com. This suggests that Lyten has moved from lab prototypes to pilot production and actual field use in those niches. The move to build a large factory indicates confidence in scaling the technology and demand materializing for it. It’s also a big signal to the battery industry and investors that lithium-sulfur is nearing readiness for prime time. We might soon see products touting “Li-S battery inside,” at least in high-end or specialized applications, as a result of this.

- Mar 2025 – Theion Raises Funds, Claims 3× Energy: In March 2025, Reuters reported that Theion raised €15 million to scale up its sulfur battery, which “stores more energy but costs much less than conventional lithium-ion batteries.” reuters.com Theion revealed some of its technical strategy publicly, saying their cells have three times the energy density of Li-ion, at one-third the cost and one-third the CO₂ emissions, as mentioned earlier reuters.com. They addressed the big concerns by stating they avoid quick corrosion by using crystalline sulfur and deal with expansion by pre-expanding the cathode structure reuters.com. The funding will help them transition from coin cells to larger pouch cells (suitable for EVs or aircraft) reuters.com. This development is a reminder that not only one but several startups (Lyten, Theion, others) are hitting milestones and attracting investment, increasing the odds that at least one will succeed commercially. It’s a bit reminiscent of the early days of lithium-ion, where multiple companies and countries were in the race – here we have U.S. and European players pushing sulfur batteries at the same time.

- 2023 – 2024 – Solving the Sulfur Cycle Life Puzzle: Throughout 2023 and into 2024, multiple research groups published advances in extending the cycle life of sulfur batteries. One highlight was the Argonne-led study (published Aug 2022 in Nature Communications) demonstrating that a redox-active interlayer can dramatically improve Li-S battery stability anl.gov. By early 2023, they reported this approach yields cells that maintain high capacity over hundreds of cycles anl.gov, inching Li-S closer to viability for everyday use. In mid-2024, another team reported a foldable, flexible Li-S battery using a special iron sulfide cathode that could even withstand being cut without failing acs.org – a novel solution for wearable or flexible electronics using Li-S. These incremental innovations are important: they address the nitty-gritty problems (like polysulfide management, mechanical stresses, etc.) one by one. Each improvement gets Li-S cells closer to meeting the rigorous demands of commercial electronics and vehicles.

- 2024 – Aluminum Battery R&D Surges: On the aluminum side, late 2024 saw interesting research too. Scientists explored new cathode materials for aluminum-ion batteries, such as cobalt sulfide, to achieve higher capacity and better understanding of charge storage mechanisms nature.com. There’s a growing body of work on “multivalent” batteries (including Al, Mg, Zn) that often share challenges and breakthroughs – for instance, improved electrolytes that help one system can sometimes be applied to another advanced.onlinelibrary.wiley.com. We also see countries like India investing in aluminum battery tech, not only via Phinergy’s aluminum-air but also in academic research to create a rechargeable aluminum battery suitable for Indian conditions (with the government funding projects under its national energy storage mission). While these haven’t made global headlines yet, they contribute to a momentum that’s building around aluminum batteries worldwide.

- Policy and Market Signals: The breakthrough stories aren’t just technical. In 2024–2025, we’re seeing strong market signals supporting these new batteries. The U.S. government’s Inflation Reduction Act (IRA) and other policies encourage domestic battery supply chains – which benefits chemistries that can be produced with locally sourced materials like sulfur (the U.S. produces a lot of sulfur from oil refining) and aluminum. Lyten’s gigafactory in Nevada and the interest of the U.S. Defense Department in lightweight Li-S batteries for soldiers or satellites are outcomes of these incentives lyten.com. In Europe, the push for sustainability makes a cobalt-free, nickel-free battery very attractive, hence EU funding for projects like Theion and others. Even in China, where lithium-ion manufacturing dominates, there have been state-supported programs for “next gen” batteries (for example, CATL reportedly working on a sodium-ion + sulfur hybrid battery for launch around 2023/24 in stationary storage). All these trends indicate that the time is ripe for aluminum and sulfur batteries – the world is looking for solutions, and technology is catching up to those needs.

In essence, the past two years have transformed aluminum and sulfur batteries from a niche lab curiosity into serious contenders for the future of energy storage. As one scientist aptly said, “We’re one step closer to seeing this technology in our everyday lives.” anl.gov That step-by-step progress is exactly what’s happening now, and the next step will be wider commercialization and scaling of these innovations.

Potential Applications and Impact on Clean Energy and Electric Vehicles

The rise of aluminum and sulfur batteries could impact a wide range of sectors. Here are some of the most promising applications and their implications:

- 🏠 Renewable Energy Storage (Grid and Home): Perhaps the biggest near-term impact will be in stationary energy storage for clean energy. One of the grand challenges of renewable power (solar, wind) is intermittency – the sun and wind aren’t available 24/7, so we need massive, economical batteries to store energy for when they’re not producing. Lithium-ion batteries have started to be used for grid storage, but they are still relatively expensive and reliant on imported materials. Aluminum-sulfur and sodium-sulfur batteries, with their dirt-cheap components, could drastically cut the cost of storing a kilowatt-hour. MIT’s Sadoway specifically targeted the home and neighborhood scale with his Al-S battery – “the size needed to power a single home or small to medium business” (on the order of tens of kWh) news.mit.edu. Such batteries would allow homeowners with rooftop solar to store daytime energy for night use cheaply, or small businesses to have backup power without a diesel generator. At larger scales, utility companies could deploy huge banks of aluminum-based or sodium-sulfur batteries to smooth out renewable generation. The University of Sydney’s team noted that their low-cost Na-S battery could “significantly reduce the cost of transitioning to a decarbonised economy” by providing affordable storage sydney.edu.au. In places without the geography for pumped hydro storage, these electrochemical solutions are key. Additionally, since these new batteries are non-flammable (important for community safety) and use abundant materials, they can be produced and installed in many regions locally – enhancing energy security. Overall, widely deployed aluminum/sulfur stationary batteries would enable higher renewable energy penetration, reduce curtailment (wasted solar/wind due to lack of storage), and help stabilize the grid with clean, dispatchable power.

- 🚗 Electric Vehicles (EVs): Lighter and higher-energy batteries are the holy grail for EVs and even electric aviation. Lithium-sulfur batteries are especially attractive here. An Li-S pack could dramatically extend the driving range of an EV without adding weight – or conversely, allow the same range with a much lighter battery, improving efficiency. For example, if an EV today needs an 600 kg Li-ion battery for 300 miles of range, a Li-S battery with 2× energy density might achieve that with ~300 kg, significantly cutting vehicle weight. This improves acceleration, handling, and reduces energy consumed per mile. It could also make electric trucks and buses more viable by freeing up payload weight. Companies like Oxis Energy (before it closed) and Sion Power worked with aerospace and automotive partners on Li-S prototype packs for long-range aircraft and EVs. In fact, Sion Power’s earlier Li-S cells powered a High Altitude Pseudo-Satellite (an unmanned solar plane) to break flight duration records in the 2010s. More recently, NASA and Airbus have looked at Li-S as one of the only ways to get the required 500 Wh/kg for practical electric passenger planes businessaviation.aero – their SABERS project’s success hints at regional electric aircraft on the horizon using sulfur batteries. Electric flying taxis and drones would likewise benefit; Theion explicitly mentioned flying vehicles as a target reuters.com. Beyond Li-S, even aluminum-air batteries have a role in EVs: they could serve as a range-extender module that you activate for long trips. Imagine an EV with a small Li-ion battery for daily commuting and an aluminum-air “auxiliary battery” that you top up (swap aluminum) only when taking a 1,000 km road trip. Such hybrid battery architectures are being contemplated in projects by Indian Oil/Phinergy and others. We should note that mainstream EVs won’t switch to a brand-new chemistry overnight – safety, longevity, and fast charging must be proven – but in the late 2020s, it’s plausible that high-end models or special-purpose vehicles might come with next-gen batteries. If they do, it could push EV performance to new heights (500+ mile ranges, very quick charging, lighter cars) and reduce reliance on critical minerals, thus enabling EV adoption at larger scale without resource bottlenecks.

- 📱 Portable Electronics and Wearables: Your future smartphone or laptop could also benefit from sulfur or aluminum batteries, though these applications demand long cycle life and low self-discharge (areas where Li-ion currently excels). A lithium-sulfur battery could make your phone run for days between charges – recall Monash University’s concept of a phone lasting 5 days on a Li-S battery advancedsciencenews.com. The weight savings are less critical for a phone, but energy density is. One challenge here is that consumer gadgets expect hundreds of cycles and years of calendar life; Li-S will need more refinement to meet that. Still, we might see niche gadgets or wearables adopting them if they offer form-factor advantages. Aluminum batteries, especially the flexible designs like Stanford’s, could enable foldable or rollable gadgets. For example, an aluminum-ion battery that’s flexible could be integrated into the strap of a smartwatch or into smart clothing. Also, because Al-ion can be made very safe (no fire risk), they could be built into devices without bulky protective casings, maybe even allowing more creative industrial design. These are speculative, but as manufacturing improves, consumer electronics could be an important market (they were for lithium-ion’s initial growth in the 1990s after all).

- ⚡ Fast-Charging Infrastructure: One less obvious but important application is using these new batteries to facilitate fast-charging of EVs and stabilize the grid. As Professor Sadoway pointed out, if many EVs try to charge at once (like multiple cars at a highway rest stop), the power demand spikes beyond what the electric grid can easily supply news.mit.edu. Instead of upgrading power lines, installing a battery buffer at charging stations is smarter – the battery slowly charges from the grid and then rapidly dumps power into cars when needed. For such buffer batteries, cost and safety are paramount, and weight is less an issue. That makes aluminum-sulfur or sodium-sulfur ideal candidates. They sit on-site, store energy cheaply, won’t catch fire, and can release charge quickly. Sadoway specifically mentioned that Al-S systems could “eliminate the need for installing expensive new power lines” for clusters of fast chargers news.mit.edu. Essentially, these batteries can act as shock absorbers for the electricity grid, soaking up surplus energy and releasing it on demand, whether it’s for EV charging surges or balancing fluctuations in renewable output.

- 🏭 Industrial and Commercial Backup: Just as telecom towers are using aluminum-air for backup power, other industries and commercial facilities could use aluminum or sulfur batteries to ensure reliability and cut reliance on diesel gensets. Data centers, for example, crave batteries that are safe, have long standby life, and are cost-effective at large scale – one can imagine sodium-sulfur battery rooms replacing banks of lithium-ion or lead-acid currently used for UPS (uninterruptible power supplies). In remote or off-grid sites, cheap batteries that don’t need frequent replacement are extremely valuable (less maintenance trips). Aluminum-sulfur batteries, being projected as very low-cost per kWh, could enable microgrids in rural or island communities, paired with solar/wind, to provide 24/7 power without breaking the bank.

- 🚀 Aerospace and Defense: The high performance of these batteries is naturally attractive for aerospace and defense applications. As noted, satellites and high-altitude drones (pseudo-satellites) have used Li-S successfully due to its light weight and good performance at low temperatures (space batteries often run cold). The U.S. military is interested in lighter batteries for soldiers (to reduce the burden of carrying many pounds of Li-ion packs) – a sulfur battery could dramatically lighten that load. Additionally, since sulfur batteries have no oxygen-releasing compounds (in contrast to Li-ion which can release O₂ in thermal runaway), they might be safer in enclosed environments like submarines or spacecraft. Aluminum-air could serve as an underwater power source for long-endurance unmanned submarines, where refueling with aluminum is feasible. The defense sector often acts as an early adopter for cutting-edge tech that later trickles down, so their investment in aluminum and sulfur battery tech can accelerate development. In fact, Lyten’s initial engagements in 2024–25 with the space, drone, and defense markets hints that defense contracts are helping prove the tech lyten.com before wider consumer use.

In all these applications, the overarching impact is enabling the clean energy transition to go faster and farther. By slashing battery costs and freeing us from the constraints of lithium-ion’s supply chain, aluminum and sulfur batteries could make electric vehicles affordable to more people (critical for decarbonizing transport), make renewable power more reliable and widespread (critical for decarbonizing electricity), and even create new possibilities like electric flight. They also carry environmental benefits in use: e.g., replacing diesel backup generators with aluminum-air or sodium-sulfur batteries cuts local air pollution and CO₂ emissions. If the technology delivers on its promise, the world could see cheaper electric cars, more resilient clean grids, and a reduction in the mining of rare metals – a positive feedback loop for both the economy and the environment.

Economic and Environmental Implications

From an economic perspective, aluminum and sulfur batteries could be disruptive in the best way possible: by driving down the cost of energy storage and diversifying the supply chain. A battery is a significant portion of the cost of an EV or a renewable energy system, so cheaper batteries mean cheaper products and faster adoption. Analysts have noted that materials like aluminum and sulfur cost a tiny fraction of lithium, nickel, or cobalt. For example, one estimate put the materials cost of aluminum-sulfur cells at only ~15% of an equivalent lithium-ion cell news.mit.edu. If those savings translate to manufacturing, we could see battery prices (per kWh) drop well below the current lithium-ion learning curve. Cheap storage could then drive economic growth by enabling new business models (like more solar farms, community storage projects, etc.) and by reducing energy costs for consumers (imagine charging your home battery every afternoon with solar and never paying peak grid rates).

There’s also a geopolitical angle: Lithium-ion production today is heavily concentrated (with China dominating cell manufacturing and countries like DRC supplying key minerals). Aluminum, however, is smelted around the world (and recycling provides a local source too), and sulfur is ubiquitous. Many countries that don’t have lithium resources do have robust aluminum industries (e.g. India, as we saw with IOC Phinergy). So aluminum-based batteries could allow more nations to build domestic battery industries without relying on imported lithium or cobalt. This diversification could reduce global supply chain risks and make the transition to electric mobility and renewable energy more resilient against shortages or political instability. In Nevada, the planned Lyten factory is an example – using U.S.-sourced sulfur and assembling batteries domestically lyten.com aligns with policies to onshore battery supply and create local jobs (they project 1,000 jobs at full scale in that one factory lyten.com).

On the environmental side, these batteries offer multiple advantages:

- Lower Carbon Footprint: Manufacturing batteries is energy-intensive, but sulfur and aluminum batteries can be made with less exotic processing. Cobalt and nickel refining are particularly carbon-heavy. By cutting those out, manufacturers can lower the CO₂ emissions per kWh of battery. Theion claimed a 2/3 reduction in carbon footprint for their sulfur batteries vs Li-ion reuters.com. Also, sulfur can be sourced as a waste product (essentially zero additional carbon cost to obtain it), and aluminum recycling uses only ~5% of the energy of primary aluminum production – so using recycled aluminum in batteries would greatly reduce their embodied energy.

- Recycling and End-of-Life: Aluminum is already one of the most recycled materials (think of aluminum cans). An infrastructure exists to melt down scrap aluminum and reuse it. If aluminum-metal batteries become common, one can imagine spent aluminum anodes being routinely collected and recycled with high efficiency – a circular economy for the battery metal. Sulfur, in a battery context, might be trickier to recycle directly from cells (especially if bound into compounds), but since it’s cheap and non-toxic, even if it ends up in landfill it’s not as big an environmental hazard as, say, lead or cadmium in older batteries. Researchers might find ways to reclaim sulfur or transform waste sulfur from batteries into useful chemicals (sulfur is also used in fertilizers, for instance). The lack of heavy metals in these batteries means less toxic e-waste if they are improperly disposed of, and ideally easier handling at recycling facilities.

- Reduced Mining Impact: The mining of lithium, cobalt, and nickel has significant environmental and social impacts – from water use in lithium brine extraction, to habitat destruction and pollution around nickel mines, to child labor issues in some cobalt mining operations. By reducing or eliminating the need for these materials, aluminum and sulfur batteries could alleviate these pressures. Aluminum is not impact-free (bauxite mining and aluminum smelting have their own issues like red mud waste and high electricity use), but those processes are well-regulated in many countries and technology is improving (e.g. inert anodes for aluminum smelting to cut emissions). And again, recycling aluminum greatly lessens the need for new mining. Sulfur usage is mostly about repurposing an existing byproduct – it could actually solve a problem (huge sulfur stockpiles) rather than create one.

- Safety and Health: Battery fires have been a concern with lithium-ion, as burning Li-ion releases toxic fumes and can cause difficult-to-extinguish blazes (as some EV fire incidents have shown). Non-flammable batteries mean fewer fire incidents, which is a safety win for society. It also means safer handling of batteries in shipping and in scrapyards. For instance, scrapped EVs with Li-ion packs pose a fire risk if damaged; an EV with an aluminum-sulfur pack might be much safer to dismantle. Likewise in consumer devices – fewer devices exploding or catching fire (thinking of infamous phone battery fires) is beneficial for public health and confidence in battery tech.

- Clean Backup Power: In places currently reliant on diesel generators for backup or remote power (islands, emergency shelters, telecom towers), replacing those with aluminum-air or sodium-sulfur batteries eliminates diesel fuel combustion, which means no greenhouse emissions, no particulate pollution, and no noise. This is a direct environmental and quality-of-life improvement. For example, telecom towers running on aluminum-air in India will produce zero local emissions, whereas diesel gensets contribute to air pollution and carbon emissions.

All told, aluminum and sulfur batteries have the potential to democratize energy storage – making it affordable and environmentally benign enough that we can deploy batteries everywhere we need them to enable a clean energy future. They won’t be a panacea (we will likely have a mix of battery technologies in use), but their entrance into the market can push costs down and force all battery makers to improve sustainability.

Of course, the economic success of these batteries isn’t guaranteed; they must prove they can be manufactured cheaply and work reliably at scale. But the recent investments and prototype successes are very encouraging. If they succeed, the payoff is not just lower-cost electric cars or better gadgets – it’s a meaningful reduction in the environmental toll of our battery usage and a boost to global decarbonization efforts.

Conclusion: A Bright Future Charged by Common Elements

Aluminum and sulfur batteries, once considered dark-horse technologies, are rapidly charging toward commercial reality. These batteries exemplify a compelling idea: use simple, abundant ingredients to solve complex energy problems. In the past couple of years, advances in chemistry and materials science have brought that idea much closer to fruition. We now have prototype aluminum-sulfur cells that can fast-charge in minutes and run for thousands of cycles nature.com, lithium-sulfur batteries that are hitting energy densities only dreamed of a decade ago reuters.com, and even aluminum-air systems starting real-world service delivering clean power evreporter.com.

Transitioning away from our reliance on rare metals and expensive imports, and toward batteries made of “basement bargain” elements like Al and S, could reshape the battery industry much like silicon did for the electronics industry – enabling vast scaling and cost reduction. As Sadoway quipped, these new batteries have “everything else you’d dream that a battery should have: inexpensive electrodes, good safety, high-speed charging, flexibility and long cycle life” news.stanford.edu. There are still kinks to iron out, but the trajectory is clear.

In the coming years, we can expect to hear about pilot deployments (perhaps a solar farm in California using MIT’s aluminum-sulfur cells, or a drone powered by a Lyten Li-S pack setting endurance records). As manufacturing ramps up, costs should fall further, and any remaining technical gaps – be it cycle life or operating temperature – will likely be solved by the intense research currently underway across the globe.

For the general public, the impact might be felt in subtle but important ways: an EV that’s cheaper and drives farther, a smartphone that stays charged over a long weekend, a neighborhood that keeps the lights on with a battery when a storm knocks the grid out, knowing that all this is done with materials as common as aluminum foil and garden fertilizer (sulfur). The world’s appetite for batteries is only growing, and aluminum and sulfur technologies ensure that we can feed that appetite sustainably.

As one scientist involved in advancing these batteries optimistically stated, “These results demonstrate … a huge impact on [battery] development. We’re one step closer to seeing this technology in our everyday lives.” anl.gov Indeed, the future where our lives are powered by aluminum and sulfur – two of Earth’s most unassuming elements – is now visibly on the horizon. The revolution in energy storage is underway, and it’s being built on the building blocks of common chemistry, innovative engineering, and the urgent drive for a cleaner, cheaper energy future.

Sources: The information and quotes in this report are drawn from recent credible sources, including peer-reviewed studies, university press releases, industry news, and Reuters reports. Key references include MIT News on the aluminum-sulfur battery news.mit.edu, Argonne National Lab’s breakthroughs in lithium-sulfur anl.gov, Reuters coverage of Theion and Lyten’s developments reuters.com, lyten.com, and interviews with industry leaders (e.g., Phinergy’s CEO on aluminum-air’s advantages evreporter.com). These and other citations throughout the text provide detailed supporting evidence for the claims made.