Table of Contents

- Executive Summary: 2025 Outlook and Key Takeaways

- Market Size, Growth Forecasts & Investment Trends (2025-2030)

- Core Tokamak Diagnostic Technologies: Current State & Innovations

- Leading Players and Strategic Initiatives (e.g., ITER, General Atomics, EUROfusion)

- Emerging Diagnostic Solutions: AI, Machine Learning, and Real-Time Analytics

- Regulatory Environment and International Collaboration

- Case Studies: Recent Breakthroughs in Major Tokamak Facilities

- Supply Chain, Manufacturing, and Component Advancements

- Challenges, Risks, and Barriers to Commercialization

- Future Outlook: Disruptive Potential and Long-Term Impact on Fusion Energy

- Sources & References

Executive Summary: 2025 Outlook and Key Takeaways

The landscape for tokamak magnetic confinement diagnostics in 2025 is characterized by rapid technological evolution, driven by the needs of advanced fusion research programs and large-scale experimental facilities. With flagship projects like ITER moving towards first plasma operations and national programs in the United States, Europe, and Asia expanding, the demand for high-precision diagnostic tools is unprecedented. In 2025, these diagnostics are pivotal for real-time measurement and control of plasma parameters such as density, temperature, magnetic field profiles, and impurity concentrations — all critical for achieving sustained fusion reactions.

The current state-of-the-art includes magnetic pick-up coils, flux loops, Hall sensors, and advanced Faraday rotation polarimetry systems. These tools are being integrated with sophisticated data acquisition and machine learning systems to provide actionable insights in real time. Leading suppliers and developers such as Thermo Fisher Scientific, Oxford Instruments, and specialized plasma diagnostic companies are providing instrumentation for both experimental and operational tokamaks around the world. ITER’s diagnostic suite, for instance, represents the largest coordinated deployment of magnetic and complementary plasma diagnostics ever attempted, with significant industry collaboration for sensor development, calibration, and system integration.

Key events in 2025 include the continued commissioning activities at ITER, where magnetic diagnostics are being brought online in preparation for plasma initiation. Major upgrades are also underway at national facilities such as the DIII-D National Fusion Facility and the EAST tokamak, with ongoing procurement and installation of next-generation diagnostic arrays. Additionally, commercial fusion ventures are investing in robust diagnostics for privately funded tokamaks, signaling a growing role for industry-driven innovation in this field.

Looking ahead, the outlook for magnetic confinement diagnostics is shaped by several trends:

- Integration of artificial intelligence and machine learning for automated anomaly detection and predictive control.

- Miniaturization and radiation hardening of sensors to withstand harsh tokamak environments.

- Expansion of remote and robotic maintenance tools for diagnostics, an area of focus for suppliers and end-users alike.

- Increased collaboration between fusion research organizations and industrial partners to standardize and scale diagnostic solutions (ITER Organization).

In summary, 2025 marks a turning point for tokamak magnetic confinement diagnostics, with technology advancements and large-scale deployments setting the stage for the next era of fusion energy research and commercialization. The synergy between public research programs and industry players will be crucial in meeting the complex diagnostic demands of future high-performance fusion reactors.

Market Size, Growth Forecasts & Investment Trends (2025-2030)

The global market for tokamak magnetic confinement diagnostics is poised for notable expansion between 2025 and 2030, driven by the increasing momentum of fusion energy research and the construction of advanced experimental facilities. As several international projects—such as ITER and China’s CFETR—move towards operational phases, demand for high-performance diagnostic systems is expected to surge. These diagnostics underpin the monitoring and optimization of plasma behavior, safety, and overall reactor performance.

In 2025, the market is characterized by significant investments from both public and private sectors. Major players include specialized instrumentation companies, vacuum technology suppliers, and advanced sensor manufacturers. Suppliers such as Oxford Instruments and Thales Group are involved in delivering key diagnostic components, including imaging systems, microwave reflectometry, and magnetic probes. These firms are augmenting their portfolios with more robust, radiation-hardened, and high-speed solutions to meet the evolving demands of next-generation tokamaks.

Ongoing projects at facilities like ITER and the Korean K-STAR are setting new benchmarks for diagnostic complexity and scale. ITER alone is projected to purchase and integrate hundreds of diagnostic units, with system integration contracts and tenders accelerating through 2025–2027. The European Domestic Agency has announced continued procurement of advanced diagnostic hardware and integration services, with spending in the hundreds of millions of euros (ITER Organization). In parallel, China’s CFETR and the US-based SPARC project are catalyzing regional supplier ecosystems and attracting new entrants focused on innovative measurement and control solutions.

Growth is further supported by increasing private investment in compact tokamak startups, many of which are engaging established diagnostic technology firms or developing proprietary systems. Companies like Tokamak Energy and Helion Energy are actively collaborating with hardware manufacturers to refine diagnostic capabilities tailored to their device architectures.

Looking ahead to 2030, market forecasts anticipate a compound annual growth rate (CAGR) in the high single digits, underpinned by the commissioning of new reactors and the retrofitting of existing devices with more advanced diagnostics. The proliferation of digitalization, AI-enabled data analytics, and remote monitoring is expected to further increase demand for sophisticated diagnostic components and integration services. As public and private fusion initiatives mature, the sector is likely to witness continued investment, technological innovation, and gradual consolidation among key suppliers and integrators.

Core Tokamak Diagnostic Technologies: Current State & Innovations

Magnetic confinement diagnostics are pivotal to the operation and development of modern tokamak reactors, underpinning plasma control, stability, and performance optimization. As the global fusion community accelerates toward devices such as ITER and DEMO, the focus in 2025 and the coming years is on expanding diagnostic precision, real-time capability, and integration with advanced control systems.

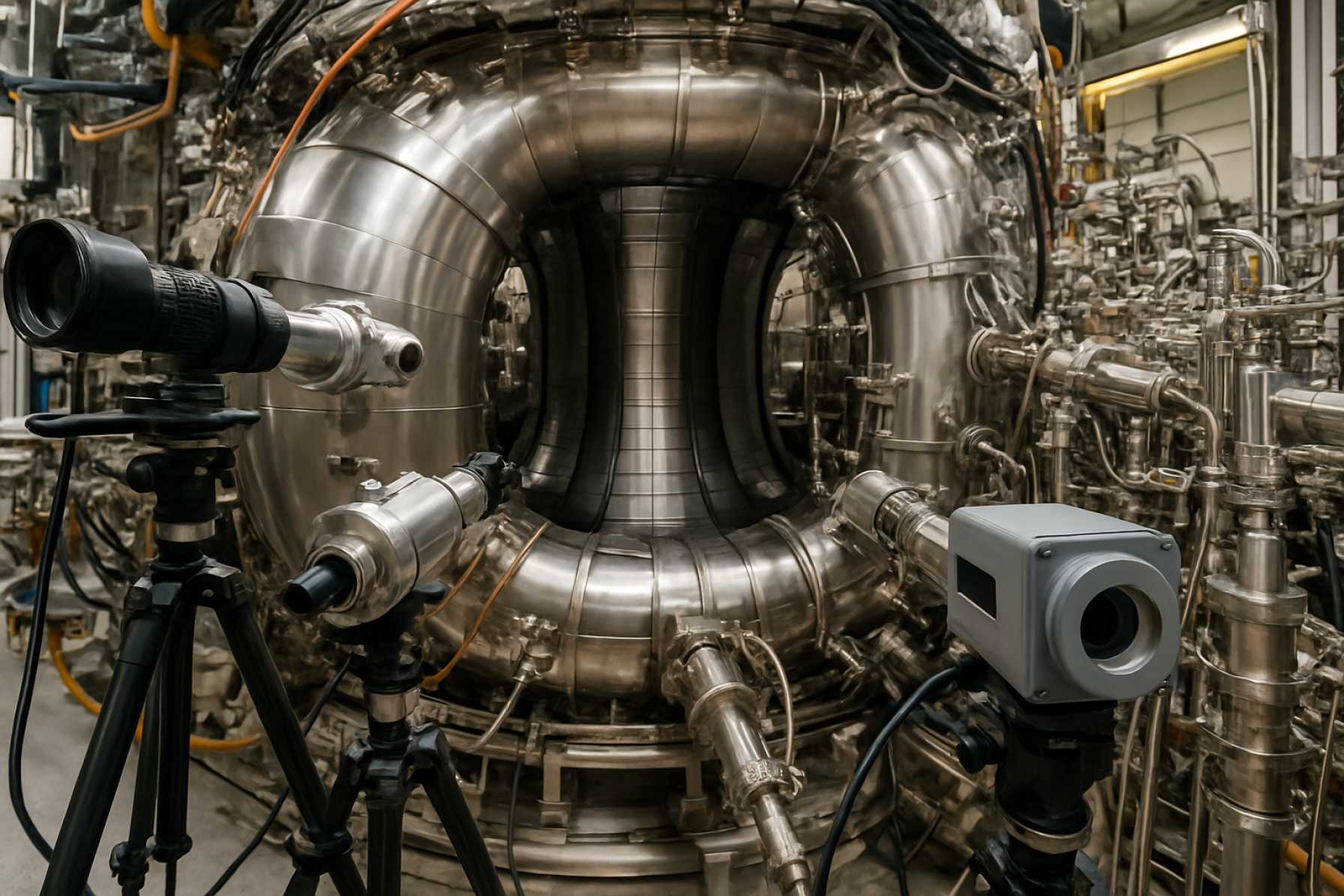

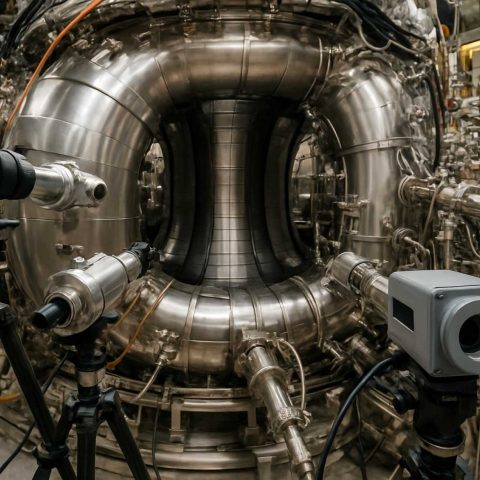

Present-day tokamaks rely on a suite of magnetic diagnostics, including Mirnov coils, flux loops, Rogowski coils, and diamagnetic loops, to measure vital parameters such as plasma position, current, shape, and instabilities. These sensors, designed for radiation hardness and high temporal resolution, are being refined to operate in the extreme environments anticipated in next-generation reactors. For example, the ITER Organization is deploying hundreds of magnetic sensors—many of which are embedded within the vessel and cryostat—to provide comprehensive mapping of magnetic fields and plasma behavior. ITER’s diagnostic suite also includes advanced magnetic probes and shielding strategies to ensure longevity and fidelity under neutron flux and high temperatures.

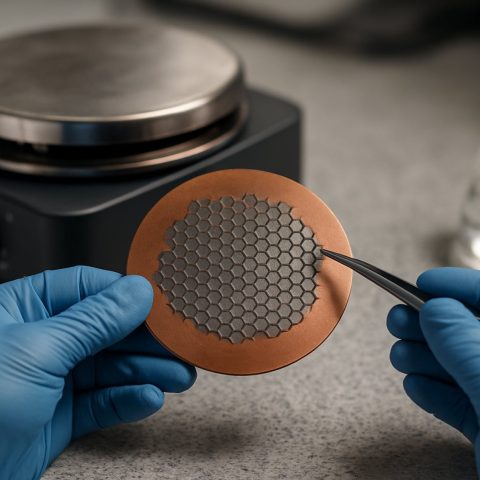

Recent innovations are focusing on miniaturization, enhanced radiation resistance, and digital signal processing. Companies such as Kyocera Corporation and Honeywell International Inc. are developing ceramic and specialty-alloy sensor housings to withstand aggressive environments, supporting the integration of diagnostics in compact and challenging locations within the tokamak. Meanwhile, suppliers like ABB Group are advancing precision current and magnetic field transducers with fast digital interfaces, enabling higher-bandwidth feedback for plasma control algorithms.

- Data Acquisition and Control: The shift to real-time magnetic diagnostic data acquisition is a major theme through 2025. High-speed digitizers, FPGA-based systems, and AI-driven pattern recognition are being adopted in experimental devices including those operated by the EUROfusion Consortium and General Atomics (DIII-D). These upgrades facilitate disruption prediction, adaptive control, and advanced scenario development.

- Remote and Robust Sensing: Optical fiber-based magnetic sensors are being piloted for their immunity to electromagnetic interference and neutron-induced degradation. Companies such as LEONI AG are contributing fiber Bragg grating technology for distributed magnetic field measurements, with early deployment in pilot facilities.

Looking ahead, the convergence of robust sensor materials, smarter data processing, and integration with digital twins is set to enhance both reliability and insight from magnetic confinement diagnostics. These advances will be critical to the operation of ITER, the design of DEMO, and the eventual commercialization of fusion energy.

Leading Players and Strategic Initiatives (e.g., ITER, General Atomics, EUROfusion)

In 2025 and the immediate years ahead, the landscape of tokamak magnetic confinement diagnostics is shaped by the strategic initiatives and collaborations of leading international organizations. The ITER Organization stands at the forefront, orchestrating the deployment of one of the world’s most sophisticated diagnostic suites within its flagship tokamak. ITER’s program prioritizes over 50 diagnostic systems—such as magnetic probes, flux loops, and advanced magnetic sensor arrays—to provide real-time monitoring and control of plasma stability and performance. These diagnostics are vital for ITER’s goal of achieving sustained, controlled fusion burning, and their integration has involved partnerships with major suppliers and research institutes across Europe, Asia, and the United States.

Within the United States, General Atomics continues to play a pivotal role through its operation of the DIII-D National Fusion Facility. The DIII-D program emphasizes magnetic fluctuation diagnostics, edge current measurements, and real-time plasma control—technologies that inform both its own experiments and contribute to the development of ITER-class diagnostics. Recent DIII-D upgrades have focused on high-bandwidth magnetic sensors and enhanced data acquisition systems, paving the way for more precise control and study of magnetohydrodynamic (MHD) phenomena.

In Europe, EUROfusion coordinates a consortium of research institutions and technology providers to support diagnostics for both the Joint European Torus (JET) and the upcoming DEMO reactor. The program is investing in next-generation magnetic diagnostics, such as fast-response Hall sensors and integrated sensor networks, which are expected to be validated at JET before deployment in DEMO. EUROfusion’s collaborative model leverages expertise from member states to address challenges in sensor durability, electromagnetic compatibility, and real-time feedback for plasma control systems.

Looking to the near future, the synergy between these leading players is expected to accelerate innovation. ITER’s commissioning phase in 2025 will serve as a global testbed for diagnostic integration, while lessons learned will inform upgrades at DIII-D, JET, and other tokamaks. Strategic initiatives are increasingly emphasizing artificial intelligence and machine learning for diagnostic data interpretation, with partnerships extending to industrial sensor manufacturers and digital technology firms. As these efforts converge, the coming years are likely to see substantial advances in both the sensitivity and robustness of magnetic confinement diagnostics, supporting the international drive toward practical fusion energy.

Emerging Diagnostic Solutions: AI, Machine Learning, and Real-Time Analytics

The landscape of tokamak magnetic confinement diagnostics is rapidly evolving as artificial intelligence (AI), machine learning (ML), and real-time analytics become integral to extracting actionable insights from complex plasma environments. In 2025 and the coming years, these emerging diagnostic solutions are anticipated to play a transformative role in both experimental fusion facilities and next-generation reactors.

AI and ML algorithms are being extensively integrated into diagnostic systems to process the vast volumes of data generated by magnetic sensors, interferometers, and spectroscopic instruments. This integration enables more accurate detection of plasma instabilities, disruptions, and subtle confinement changes. For instance, deep learning models are being developed to analyze magnetic probe data and identify precursor events associated with disruptions, offering operators advanced warning and the potential for automated control interventions. Real-time analytics platforms, leveraging high-speed data acquisition and edge computing, are facilitating rapid decisions by correlating signals from multiple diagnostics, thus improving plasma performance and machine protection.

Several leading fusion organizations are at the forefront of deploying these technologies. At ITER, extensive AI-driven research is underway to enable real-time monitoring and control of plasma parameters, with the goal of optimizing confinement and mitigating disruptions. ITER Organization is collaborating with software and instrumentation partners to develop scalable analytics solutions, ensuring that diagnostic systems can keep pace with the anticipated data rates and complexity of full-scale burning plasma operations. In parallel, companies like Tokamak Energy and General Atomics are integrating real-time ML analytics within their diagnostic suites to enhance the operational reliability and scientific output of their respective tokamaks.

Manufacturers of diagnostic instrumentation are also adapting product lines to support embedded AI and edge computing capabilities. This includes modular data acquisition platforms and high-speed digitizers designed for in-situ ML inference, as seen in offerings from leading suppliers. Such capabilities are expected to become standard in newly commissioned diagnostics through 2026 and beyond, driven by the requirements of facilities like ITER Organization and national fusion programs.

Looking ahead, the fusion community anticipates that emerging AI, ML, and real-time analytics solutions will not only enhance diagnostic accuracy but also enable unprecedented levels of automation in plasma control. This will be pivotal for achieving sustained, stable plasma operations in both experimental and commercial fusion reactors, marking a significant step toward practical fusion energy.

Regulatory Environment and International Collaboration

The regulatory environment and international collaboration landscape for tokamak magnetic confinement diagnostics are evolving rapidly as the fusion sector approaches critical milestones in 2025. The increased focus on safety, data integrity, and interoperability across borders is driving both harmonization of standards and collaborative efforts between leading research organizations and industrial suppliers.

One of the most significant regulatory developments is the ongoing adaptation of nuclear regulatory frameworks to address the unique features of fusion devices, particularly in the realm of diagnostics that monitor plasma parameters and confinement performance. In the European Union, the approach is informed by the European Atomic Energy Community (Euratom), which continues to refine regulatory oversight for fusion projects, with special emphasis on ensuring that diagnostics systems comply with rigorous safety, electromagnetic compatibility, and data management standards. The ITER Organization, as the flagship multinational project, sets many benchmarks for best practices in both regulatory compliance and operational transparency, providing templates that are being adopted by newer projects globally.

International collaboration remains a cornerstone of diagnostics development and deployment, as no single nation possesses all the expertise or infrastructure required for the most advanced measurement systems. Major tokamak projects such as ITER and the forthcoming EUROfusion DEMO project rely on consortia of research institutions and industrial partners to design, validate, and implement diagnostics. For example, collaborations among UK Atomic Energy Authority, Culham Centre for Fusion Energy, and their counterparts in Japan, South Korea, and the United States, have accelerated the development of advanced magnetic and optical diagnostics that meet stringent regulatory and operational demands.

On the industry side, suppliers such as Thales Group and Oxford Instruments are closely engaged with both regulators and research consortia. Their involvement ensures that emerging diagnostic technologies—ranging from high-precision magnetic sensors to robust data acquisition platforms—are developed in accordance with evolving international standards, including those for cybersecurity and quality assurance.

Looking ahead, the next few years are expected to witness deeper integration of regulatory requirements into the design phase of diagnostic systems, reducing time-to-approval and enhancing interoperability between facilities. Additionally, formalized knowledge-sharing platforms and working groups under the auspices of organizations such as International Atomic Energy Agency (IAEA) will play an increasing role in disseminating best practices, facilitating cross-border licensing, and streamlining the regulatory acceptance of critical diagnostics for new tokamak installations worldwide.

Case Studies: Recent Breakthroughs in Major Tokamak Facilities

Recent years have witnessed significant advances in magnetic confinement diagnostics across major tokamak facilities, with implications for both experimental plasma physics and the design of next-generation fusion reactors. In 2025, several flagship tokamaks have reported notable breakthroughs, driven by innovations in diagnostic hardware, real-time data acquisition, and integrated analysis platforms.

One key development has been the deployment of advanced magnetic probe arrays and Faraday-effect polarimetry systems at leading facilities. For example, the ITER Organization has made strides in the integration and initial testing of its magnetic diagnostic suite. This includes in-vessel and ex-vessel magnetic sensors designed to operate under extreme neutron flux and thermal loads. The system’s ability to provide high-fidelity measurements of the plasma current profile and edge magnetic fluctuations is central to ITER’s mission of achieving stable, high-confinement operation.

At the EUROfusion-supported JET (Joint European Torus), recent campaigns have leveraged fast magnetic diagnostics to resolve transient phenomena, such as edge-localized modes (ELMs) and disruptions, with sub-millisecond temporal resolution. These data have enabled the validation of magnetohydrodynamic (MHD) stability models and informed real-time plasma control algorithms. JET’s diagnostic upgrades, including improved Rogowski coils and saddle loops, have also contributed to more precise reconstructions of plasma shape and position, crucial for optimizing performance during deuterium-tritium experiments.

In Asia, the National Institutes for Quantum Science and Technology (QST) is advancing magnetic diagnostics on the JT-60SA tokamak. The facility’s multi-coil magnetic sensor arrays are supporting active feedback control experiments, helping to sustain long-duration high-beta plasmas. These efforts are complemented by collaborations with commercial partners providing high-reliability, radiation-hardened sensor technologies.

Looking ahead, the outlook for tokamak magnetic confinement diagnostics is characterized by continued integration of artificial intelligence and machine learning for real-time data interpretation. The application of these tools is expected to enhance disruption prediction and enable autonomous control strategies. Additionally, next-generation diagnostic devices are being developed with improved spatial resolution, greater immunity to radiation damage, and compatibility with remote handling systems—features vital for DEMO-class reactors and commercial fusion demonstration plants anticipated by the end of the decade.

Collectively, these case studies demonstrate the pivotal role of advanced magnetic diagnostics in enabling the safe, efficient, and scalable operation of magnetic confinement fusion devices, forming a cornerstone for future energy systems.

Supply Chain, Manufacturing, and Component Advancements

The supply chain and manufacturing landscape for tokamak magnetic confinement diagnostics is witnessing significant evolution as global fusion initiatives—such as ITER and next-generation private-sector projects—advance towards operational milestones in 2025 and the following years. The demand for precision diagnostics, including magnetic sensors, flux loops, Mirnov coils, and advanced data acquisition systems, has spurred both established manufacturers and specialized suppliers to scale up and refine their offerings.

Key suppliers are investing in enhanced fabrication processes for high-precision magnetic probes, often integrating advanced materials to withstand extreme thermal and neutron environments typical of modern tokamaks. For instance, Oxford Instruments continues to supply superconducting materials and instrumentation, which underpin the sensitive magnetic measurement systems required in these reactors. Similarly, American Superconductor Corporation specializes in the delivery of high-performance superconducting wires and related components crucial for both main magnets and diagnostic assemblies.

The integration of diagnostics into ever-larger and more complex tokamak devices, such as ITER and DEMO prototypes, has necessitated close collaboration between suppliers and research organizations. Companies like Thales Group are providing advanced electronic subsystems for signal processing and control, while LEONI supplies radiation-resistant cabling and connectors, which are vital for reliable data transmission from in-vessel sensors to control rooms.

On the manufacturing front, there is a push toward modularity and rapid custom prototyping, enabled by advances in precision machining and additive manufacturing. This trend reduces lead times and allows for quicker adaptation to evolving diagnostic requirements as new tokamak designs emerge. Additionally, quality assurance protocols—such as those championed by TÜV Rheinland—are being increasingly adopted to certify component resilience and performance under severe operational stresses.

Looking ahead to 2025 and beyond, the supply chain is expected to become more robust and agile, with greater regional diversification to mitigate geopolitical and logistical risks. Industry partnerships with fusion consortia are expected to deepen, as exemplified by the long-term agreements between suppliers and international projects like ITER. The outlook is for continued investment in manufacturing capacity, digital integration for diagnostics, and the development of next-generation materials, all of which are pivotal for supporting the ambitious operational goals of future tokamak reactors.

Challenges, Risks, and Barriers to Commercialization

Tokamak magnetic confinement diagnostics are pivotal for the advancement of fusion energy, enabling precise measurement and control of plasma behavior. However, as the sector moves toward commercial demonstration in the latter half of the 2020s, several significant challenges, risks, and barriers persist.

One of the primary challenges is the harsh operational environment in fusion reactors. Diagnostics must function reliably amidst intense neutron flux, high temperatures, and strong electromagnetic fields. These conditions can degrade diagnostic components, reduce measurement accuracy, and shorten device lifespans. For example, optical systems may suffer from radiation-induced darkening, while electronic sensors can experience noise and failure from neutron activation. Ensuring the resilience and longevity of diagnostic tools remains a major research focus for device manufacturers and integrators such as AMSC (American Superconductor Corporation) and system suppliers engaged with ongoing projects.

Another significant barrier is the integration of real-time, high-resolution diagnostics with tokamak control systems. Next-generation reactors like ITER and emerging private-sector projects demand sophisticated feedback to maintain plasma stability and optimize confinement. Achieving this involves not only technical advancements in sensor resolution and speed but also robust data acquisition and processing electronics capable of operating in close proximity to the plasma. Companies such as Thermo Fisher Scientific, active in high-end scientific instrumentation, are developing detectors and electronics suitable for these demanding applications.

In 2025, supply chain constraints and the limited availability of radiation-hardened components continue to impact development timelines. The specialized materials and sensors required for fusion diagnostics are produced by a small number of vendors, with long lead times and significant cost. This bottleneck is amplified by the need to qualify each component for nuclear environments, a process that can exceed several years for new diagnostic technologies. Industry leaders like Mirion Technologies are working to expand their offerings of nuclear-grade detectors, but the pace of qualification remains a barrier to rapid innovation.

- Data security and integrity also emerge as risks, especially as diagnostics become increasingly digitized and networked. Protecting sensitive measurement data from cyber threats is crucial for both competitive and safety reasons.

- Regulatory and standardization hurdles remain, since few globally harmonized protocols exist for fusion diagnostic systems. This complicates collaboration between international projects and slows the adoption of new solutions.

- Lastly, the financial risk is notable. The cost of developing, testing, and deploying advanced diagnostics in prototype and commercial-scale reactors is substantial, with uncertain return on investment until fusion becomes commercially viable.

Looking ahead, overcoming these challenges will require coordinated efforts among diagnostic equipment manufacturers, fusion developers, and regulatory bodies. Strategic investment in robust, modular, and scalable diagnostic solutions, along with accelerated component qualification, will be essential for commercializing magnetic confinement fusion by the end of the decade.

Future Outlook: Disruptive Potential and Long-Term Impact on Fusion Energy

The future landscape of tokamak magnetic confinement diagnostics is poised for significant evolution as fusion energy research intensifies in 2025 and beyond. With flagship projects like ITER advancing towards first plasma and next-generation devices under design, the demand for precise, robust diagnostic systems is greater than ever. Magnetic diagnostics, crucial for measuring and controlling the plasma’s position, shape, stability, and performance, are increasingly leveraging advancements in sensor technology, data acquisition, and real-time control algorithms.

By 2025, ITER’s integrated diagnostic suite will serve as both a proving ground and a benchmark for the field. ITER’s array of magnetic sensors—including pickup coils, Rogowski coils, and flux loops—are engineered for extreme radiation tolerance and reliability, setting new standards for future reactors. The collaboration with industrial players and research institutes is fostering innovations in sensor miniaturization, digital signal processing, and electromagnetic compatibility, which are essential for the operational demands of burning plasma regimes (ITER Organization).

In parallel, the introduction of advanced materials such as high-temperature superconductors and radiation-hardened alloys is enabling manufacturers to produce diagnostic components capable of surviving the harsh environments anticipated in DEMO-class reactors. Companies specializing in fusion instrumentation are scaling up their R&D efforts to deliver next-generation magnetic probes, integrating fiber-optic and MEMS-based technologies for enhanced sensitivity and spatial resolution. Notably, suppliers like Tokamak Energy and TRIUMF are reported to be collaborating on advanced magnetic measurement systems for pilot plants expected later this decade.

Machine learning and artificial intelligence are also making inroads into magnetic diagnostic applications. Real-time plasma control systems leveraging AI-driven data interpretation are under active development, aiming to improve disruption prediction, optimize confinement, and ensure operational safety. This convergence of diagnostics and intelligent control is expected to become standard in the operation of both government-led and private fusion devices through the late 2020s (EUROfusion).

In summary, as fusion projects transition towards demonstration and commercialization, magnetic confinement diagnostics remain a critical frontier. The integration of new sensor technologies, advanced materials, and intelligent systems will not only enhance plasma control but could also accelerate the realization of practical fusion energy. The coming years will likely see disruptive progress in this sector, with ripple effects extending across the global energy landscape.

Sources & References

- Thermo Fisher Scientific

- Oxford Instruments

- ITER Organization

- Thales Group

- Tokamak Energy

- Helion Energy

- Honeywell International Inc.

- ABB Group

- EUROfusion Consortium

- General Atomics

- LEONI AG

- General Atomics

- EUROfusion

- International Atomic Energy Agency (IAEA)

- National Institutes for Quantum Science and Technology

- American Superconductor Corporation

- TÜV Rheinland

- Mirion Technologies

- TRIUMF