Technical ceramics – also known as advanced or high-performance ceramics – are engineered materials prized for exceptional properties that traditional ceramics (like pottery) and even metals or plastics cannot match ceramtec-group.com. They are defined by extreme hardness, ability to withstand very high temperatures, chemical inertness, and excellent wear resistance, among other traits ceramtec-group.com. These outstanding material properties enable applications that were once “previously unthinkable,” from medical implants to rocket engine parts ceramtec-group.com. In essence, technical ceramics excel where conventional materials fail – offering durability and stability under intense mechanical stress, heat, or corrosive environments wundermold.com. This makes them critical in industries such as electronics, aerospace, energy, and healthcare, where components must perform under extreme conditions.

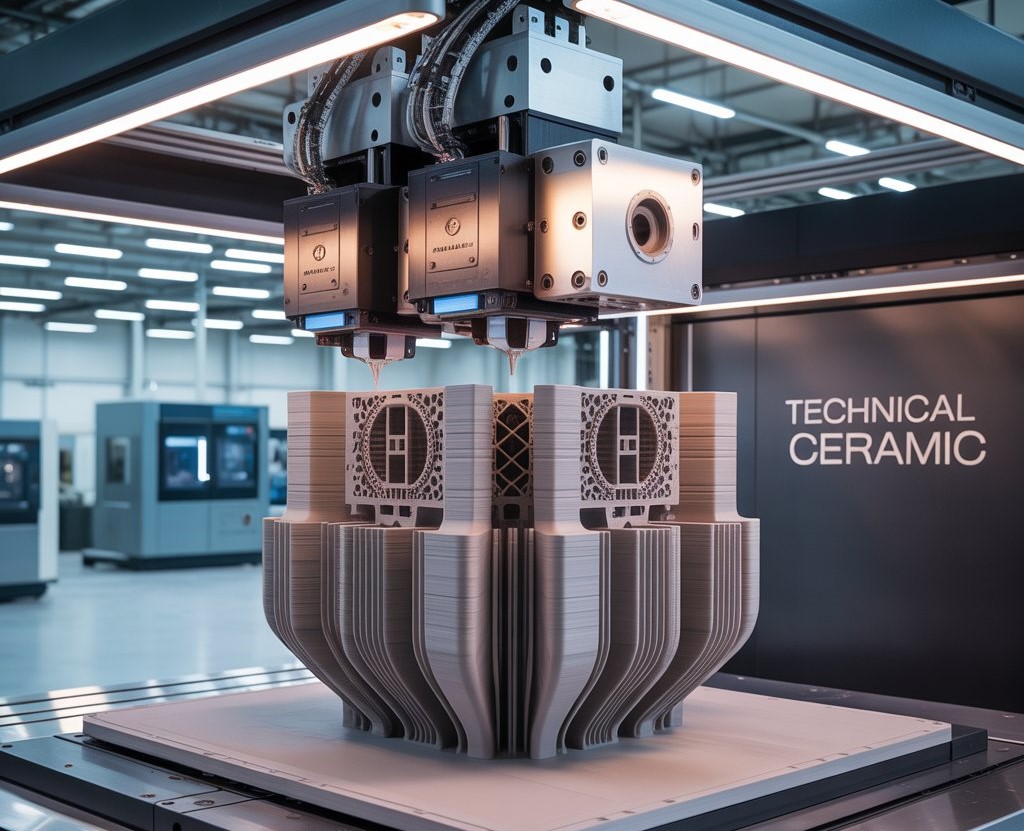

Despite their advantages, advanced ceramics have historically been difficult to shape and manufacture. Traditional processes involve pressing or molding a powder and firing it like pottery, followed by extensive machining (grinding) to achieve final dimensions – a time-consuming method prone to cracks or defects aerospaceamerica.aiaa.org. Here is where 3D printing (additive manufacturing) enters the scene. By building parts layer-by-layer from ceramic materials, 3D printing offers new design freedom for ceramics, eliminating the need for expensive molds and reducing machining requirements tctmagazine.com. Complex geometries that were impractical before – like internal channels, lattice structures, or custom-tailored shapes – can now be formed directly. According to experts at the U.S. Naval Research Lab, with 3D printing “you’re basically getting more customization in terms of what kind of a ceramic you can make” as opposed to being limited by a mold or die aerospaceamerica.aiaa.org. In short, additive manufacturing is poised to revolutionize technical ceramics, enabling innovative products and applications while preserving the superior mechanical, thermal, and chemical properties that make these materials so important global.kyocera.com, ceramtec-group.com.

How 3D Printing Works with Technical Ceramics

Printing technical ceramics is fundamentally different from printing common plastics or metals, mainly because ceramics must be sintered (fired) to achieve their final strength. Nearly all ceramic 3D printing today is an indirect process: a printer creates a “green” part in the desired shape, which is then post-processed through debinding (removing any binders or polymers) and high-temperature sintering to densify the ceramic aniwaa.com. This two-step approach is necessary to turn the printed object into a fully hard, solid ceramic. It also means designers must account for shrinkage during sintering (often on the order of ~15–20% linear shrinkage), as the part can shrink and lose volume when the binder burns out and the particles fuse mdpi.com. Controlling this shrinkage and avoiding distortion or cracks is one of the key challenges in ceramic additive manufacturing mdpi.com.

Several 3D printing methods have been adapted to fabricate ceramic parts, each with its own technique and considerations:

- Binder Jetting: This process uses a powder bed of ceramic particles and a liquid binder jetted layer-by-layer to glue the particles into the shape. After printing, the fragile “green” part is removed and sintered to full density. Binder jetting is currently the only ceramic AM method that can produce relatively large parts at high speed, and it doesn’t require support structures during printing aniwaa.com. However, the trade-offs include lower resolution and significant porosity – after sintering, parts often retain 20–30% porosity unless further infiltrated aniwaa.com. Surfaces are generally rougher, and fine details or internal hollow features are limited (unbound powder must be able to escape) aniwaa.com. Due to the inherent porosity, binder jetting works well for applications like porous cores, filters, and crucibles where some permeability is acceptable aniwaa.com.

- Stereolithography (SLA/DLP): In ceramic SLA, a photosensitive resin loaded with ceramic powder is cured by a UV laser or projector to form each layer aniwaa.com. The printed piece (embedded in a polymer matrix) is then washed, post-cured, and sintered to burn out the resin and densify the ceramic. This technology – sometimes called lithography-based ceramic manufacturing – offers excellent resolution and high density. It can produce very intricate details and thin walls, and supports a wide range of ceramic materials (alumina, zirconia, silicon-based ceramics, and even bioceramics like hydroxyapatite) aniwaa.com. SLA-printed ceramic parts can reach ~99% of theoretical density after sintering, comparable to traditionally made ceramics aniwaa.com. The downside is cost and complexity: industrial ceramic SLA printers are expensive (often $150k to $500k) aniwaa.com, and the process involves careful handling (e.g. removing excess resin, UV post-curing). Additionally, one cannot print hollow, trapped cavities with resin methods – any internal void would be filled with liquid resin that cannot be drained aniwaa.com.

- Material Extrusion (Fused Filament/Paste Deposition): This approach extrudes a filament or paste that contains ceramic powder mixed with polymers or binders, similar to FDM printing of plastics aniwaa.com. One example is the FFF (fused filament fabrication) method using special filaments (like Nanoe’s Zetamix), loaded with ~50% ceramic powder. After printing the part layer by layer, the binder plastic is debinded (often by thermal or solvent removal) and the remaining ceramic is sintered. Ceramic extrusion is appealing for its simplicity and affordability – in fact, certain ceramic filaments can be run on standard desktop 3D printersaniwaa.comaniwaa.com. It also yields fully dense parts (e.g. Zetamix reports ~99% density after sintering) on par with SLA aniwaa.com. The process requires minimal post-print cleanup (no loose powder or resin baths) aniwaa.com. However, the layer resolution is usually coarser than SLA (roughly 100 µm differences) and the printable size is limited – one cannot make the very large parts possible with binder jetting aniwaa.com. A related technique, often called robocasting or direct ink writing, extrudes a paste or slurry through a nozzle. Robocasting has successfully printed complex ceramics and is valued for being “cheap and simple” while accommodating larger structures aerospaceamerica.aiaa.org. The key challenge for extrusion-based printing is formulating a paste with the right rheology: it must flow smoothly through the nozzle but set quickly enough to hold its shape without cracking as it dries aerospaceamerica.aiaa.org. Optimizing binders and solvents is crucial to prevent defects in these printed strands aerospaceamerica.aiaa.org.

- Material Jetting / Inkjet: A high-end method used by companies like XJet involves jetting tiny droplets of a ceramic nanoparticle suspension onto a build plate, often with hundreds of nozzles depositing material simultaneously aniwaa.com. The droplets dry and solidify layer by layer, followed by sintering to fuse the nanoparticles. Inkjet (also called NanoParticle Jetting) can achieve exceptional precision and fine feature detail, making it ideal for small complex parts such as miniaturized electronics or surgical devices aniwaa.com. The trade-offs are that it’s slow, very costly, and generally limited to smaller parts aniwaa.com. It also requires extensive support and removal processes for the delicate green parts. Because of its precision, inkjet-printed ceramics are being explored for advanced applications like 5G antenna components and microwave devices that require intricate ceramic geometries.

Regardless of the printing method, all ceramic AM parts must undergo debinding and sintering. Debinding carefully removes the polymer or binder (by heat or solvent) to avoid cracking – for instance, too rapid heating can cause internal pressures that split the part. Sintering then densifies the ceramic at temperatures often between ~1200–1600 °C (depending on the material). During sintering, significant shrinkage occurs as the particles fuse; as one research review notes, achieving dimensional stability despite this ceramic shrinkage is often a “significant challenge” requiring optimized binders and sintering schedules mdpi.com. Advanced techniques (like adding inorganic binders or sintering aids) are being studied to reduce shrinkage and distortion mdpi.com. Another challenge is avoiding residual porosity – for example, binder jet parts tend to have residual pores if not further densified, which can reduce mechanical strength aniwaa.com. Post-sintering finishing (such as diamond grinding) may be needed for tight tolerances, since ceramics cannot be easily sanded or machined with ordinary tools. Despite these hurdles, successful 3D printed ceramic parts exhibit material properties comparable to traditionally made ceramics global.kyocera.com. Companies report that printed alumina or zirconia can reach the same density, strength, and performance as parts made by molding or pressing, just with far greater geometric complexity global.kyocera.com.

Materials Used in Ceramic 3D Printing

A variety of technical ceramic materials have been adapted for 3D printing, each chosen for its particular properties and application areas. Common materials include:

- Alumina (Al₂O₃): Alumina is one of the most widely used technical ceramics. It is a versatile oxide ceramic known for high hardness, strength, stiffness, and excellent wear resistance global.kyocera.com. Alumina withstands high temperatures and is electrically insulating, making it useful in both structural and electronic applications. It’s also relatively cost-effective, so it often serves as a “workhorse” material for ceramic AM process development. Alumina parts see use in everything from semiconductor manufacturing components to biomedical implants. (In 3D printing, alumina slurries like Lithoz’s LithaLox are popular choices due to their purity and consistency lithoz.com.)

- Zirconia (ZrO₂): Zirconium oxide is prized for its high toughness and resistance to crack propagation, which is unusual in ceramics global.kyocera.com. It has a fracture toughness and strength above that of alumina, and can endure impact or cyclic loads better (hence its nickname “ceramic steel”). Zirconia is often used in medical and dental applications – for example, 3D printed zirconia dental crowns and implants – thanks to its biocompatibility and strength. It also has low thermal conductivity and is used in thermal barrier coatings. Some 3D printers use yttria-stabilized zirconia formulations, which maintain a desirable crystal phase for toughness. For instance, 3Y-TZP zirconia can be printed to create dense, smooth parts that are even suitable for hip implants or durable wear components global.kyocera.com.

- Silicon Carbide (SiC): A non-oxide ceramic, silicon carbide is extremely hard (approaching diamond on the hardness scale) and maintains strength at very high temperatures. SiC also has high thermal conductivity and is very chemically inert. These properties make it ideal for extreme environment applications: engine components, cutting tools, furnace hardware, rocket nozzles, and even body armor. However, SiC’s high melting point and lack of plasticity make it challenging to sinter; often special atmospheres or pressure (like hot pressing) are used in conventional manufacturing. In 3D printing, SiC has been demonstrated via indirect methods (e.g. printing a polymer part and converting it to SiC by reaction bonding azom.com). Some binder jetting systems can also print SiC objects that are later infiltrated/sintered. Silicon carbide’s thermal stability is a major draw – it can survive where most metals would soften. For example, “materials like silicon carbide, alumina, and zirconia maintain their integrity at temperatures far beyond metals or polymers” in turbine engines and heat shields wundermold.com.

- Silicon Nitride (Si₃N₄): Another important non-oxide ceramic, silicon nitride combines high temperature strength with toughness and thermal shock resistance. It’s used in demanding mechanical parts like turbocharger rotors, bearings, and molten metal handling because it can handle rapid temperature changes and has a low density (lighter than steel). Si₃N₄ also has good wear and impact resistance. In additive manufacturing, silicon nitride powders have been formulated for processes like SLA and binder jetting. For instance, Lithoz offers a LithaNit 780 slurry for printing silicon nitride components lithoz.com. These printed Si₃N₄ parts can find uses in aerospace (e.g. combustion linings) or even cutting tools. A notable property is that silicon nitride is less brittle than many ceramics due to its grain structure, so printed parts exhibit reliable performance under load.

- Aluminum Nitride (AlN): Aluminum nitride is valued for its exceptional thermal conductivity (it conducts heat almost as well as some metals while remaining an electrical insulator). This unique combination makes AlN the material of choice for heat sinks and substrates in high-power electronics. 3D printing AlN is still emerging, but companies like Lithoz have developed AlN printing processes (their LithaFlux material) lithoz.com. Potential applications include custom-designed electronic packaging components that dissipate heat efficiently or even RF components that leverage its dielectric properties.

- Hydroxyapatite (HA) and Bioceramics: Hydroxyapatite, a calcium phosphate, is a bioactive ceramic used in bone grafts and implants because it closely resembles the mineral component of bone. 3D printing of HA and related bioceramics (like tricalcium phosphate, TCP) has opened new frontiers in tissue engineering – surgeons can get patient-specific bone scaffolds that eventually integrate and dissolve as real bone grows ceramics.org. Ceramic 3D printers tailored for medical use can produce HA scaffolds with porous structures ideal for cell growth. For example, Lithoz’s medical line prints HA and TCP scaffolds for research in regenerative medicine lithoz.com. Other bioceramics, such as zirconia toughened alumina, are used for dental implants that benefit from both strength and bio-inertness.

- Composite and Specialized Ceramics: Technical ceramics can also be blended or formed into composites to tweak their properties. One common example is Zirconia Toughened Alumina (ZTA), which combines alumina’s hardness with some zirconia to improve toughness (resistance to cracks). Conversely Alumina Toughened Zirconia (ATZ) starts with zirconia and adds alumina to improve hardness. These composites can be printed to achieve a balance of properties for applications like cutting tool inserts or orthopedic implants. There are also ceramic-matrix composites (CMCs) where ceramic fibers (e.g. carbon or SiC fibers) are incorporated for extreme thermal applications like jet engine turbine blades – though printing CMCs is in early stages. Finally, research is ongoing in printing functional ceramics: for example, piezoelectric ceramics (like barium titanate or lead zirconate-titanate) for sensors, or glass-ceramics and even pure glass via adapted 3D printing processes 3dprintingindustry.com. The range of printable ceramics is rapidly expanding as material science advances.

Applications Across Industries

Thanks to their unique properties, 3D printed technical ceramics are finding use in a wide array of industries. Here are some of the key application areas and examples:

- Aerospace & Defense: The aerospace industry leverages ceramics for high-temperature and high-stress components. 3D printed ceramics are used to make turbine engine parts, rocket nozzles, thermal protection tiles, and even complex casting cores for manufacturing metal turbine blades wundermold.com, lithoz.com. Because ceramics can be lighter than metals and survive scorching temperatures, they’re ideal for parts like nose cones or wing leading edges on hypersonic vehicles, which see temperatures >2000 °C. Notably, printed ceramic molds and cores have enabled new designs in jet engine development – for example, Honeywell used 3D printed ceramic molds to prototype turbine blades, dramatically speeding up their R&D cycle tctmagazine.com. In satellites and defense systems, ceramic RF (radio-frequency) components are printed to enhance signal quality in harsh space conditions lithoz.com. Sensors for aerospace can also benefit: the German Aerospace Center (DLR) has deployed a 3D printed zirconia temperature sensor head only 0.3 mm thin, leveraging ceramics’ stability at high heat lithoz.com.

- Automotive: Technical ceramics appear in engines, exhaust systems, and other automotive components that face heat and wear. For instance, 3D printed ceramics serve in catalytic converter substrates (ceramic honeycomb structures) and lightweight brake discs, taking advantage of their ability to handle high temperatures with minimal thermal expansion wundermold.com. Ceramic spark plug insulators and fuel injectors are other examples – ceramics’ electrical insulation and heat resistance improve reliability in the ignition system. Because additive manufacturing removes tooling constraints, car manufacturers can prototype complex ceramic parts much faster. Ceramic parts also contribute to fuel efficiency; e.g. ceramic engine components can allow higher operating temperatures and thus more efficient combustion. As one industry source noted, “Ceramic’s resistance to extreme conditions makes it perfect for critical components like spark plugs, brakes, and sensors,” which 3D printing can produce without the costly tooling of traditional methods prodways.com. This enables quicker design iterations for high-performance engines and even custom parts for motorsports or classic car restorations.

- Energy and Power Generation: The energy sector relies on ceramics in applications ranging from power plants to batteries. In 3D printing, a notable use is in solid oxide fuel cells (SOFCs) – these fuel cells operate at ~800 °C and use ceramic electrolytes and electrodes. Researchers have 3D printed intricate ceramic fuel cell components to improve performance and lower costs 3dprintingindustry.com. In nuclear energy, ceramics like silicon carbide are studied for fuel cladding and printed lattice structures that can survive radiation and heat. Gas turbines benefit from ceramic cores (for casting blades) and potentially from printed CMC parts for hotter, more efficient turbines. Even renewable energy sees ceramic AM: for example, printed ceramic molds for casting engine parts in wind turbines, or ceramic parts in solar thermal reactors. As the Wunder Mold company describes, technical ceramics are “essential in fuel cells, nuclear reactors, and even solar panels”, providing longevity and performance in these systems wundermold.com. The ability to 3D print them means faster prototyping of new designs – such as novel heat exchangers or micro-turbine components with internal cooling channels that only ceramics can endure.

- Medical & Dental: The medical field has warmly embraced ceramic 3D printing for its combination of biological compatibility and precision. Ceramics like zirconia are used for dental restorations (crowns, bridges) and can now be 3D printed to patient-specific shapes, offering a faster alternative to milling. In orthopedics, 3D printed bone scaffolds made of bioceramics (hydroxyapatite or tricalcium phosphate) are used to fill bone defects and encourage new bone growth ceramics.org. These scaffolds can be made porous and complex in ways traditional bone graft substitutes cannot, potentially improving healing for large bone injuries. Technical ceramics also appear in surgical tools and medical devices: for example, ceramic drill guides, endoscopic nozzles, or components for MRI machines (where metal would cause interference). Ceramics are valued for being sterilizable, hard, and non-reactive. They’re even used in middle-ear implants and dental implants due to their bio-inertness. With 3D printing, surgeons can get ceramic implants tailored exactly to a patient’s anatomy – such as a custom ceramic spinal cage or a cranial implant – combining the strength of ceramics with the personalization of AM. In short, ceramics’ “strength and biocompatibility” make them ideal for implants and tools, and additive manufacturing now provides the means to produce these items in custom forms quickly wundermold.com.

- Electronics & Semiconductors: Many electronics depend on ceramic materials for insulation or as circuit substrates, and 3D printing is opening up new possibilities here. Technical ceramics like alumina and aluminum nitride are used as electrical insulators on high-voltage components and as substrates for microchips and LEDs due to their thermal conductivity wundermold.com. With 3D printing, engineers are creating ceramic circuit boards with embedded cooling structures or unusual form factors. For high-frequency communications (5G, radar, satellite), 3D printed dielectric resonators and antennas made of ceramic can offer superior performance – complex geometries can be printed to tune frequencies in ways not possible with standard manufacturing. One recent example involved printing a dual-band ceramic antenna that achieved performance gains by leveraging intricate internal features xjet3d.com. Additionally, in the microwave and vacuum electronics realm, ceramic components like waveguides, RF filters, and vacuum tube parts are being printed. These devices exploit ceramics’ stability under high voltages and heat. The semiconductor industry also uses ceramic 3D printing for making custom wafer processing equipment parts (for example, ceramic lift pins, nozzles, or etch chamber components) with quick turnaround. Overall, additive manufacturing allows electronic ceramics to be prototyped and produced with geometries that optimize electrical properties while maintaining the necessary insulating or heat-resistant characteristics.

- Industrial & Chemical Processing: In heavy industry, technical ceramics solve problems where metals would corrode or wear out. 3D printed ceramics are used for pump impellers, valve components, nozzles, and pipes that handle corrosive chemicals or abrasive fluids. For instance, acid-resistant ceramic valves can be printed for custom chemical reactors, eliminating expensive multi-part assemblies. Ceramics like silicon carbide and alumina show remarkable resistance to acids, alkalis, and solvents, so printed parts find use in chemical processing equipment that demands longevity wundermold.com. Another niche is wear parts: factories can print ceramic guides, cutters, or extrusion dies that last far longer than steel in high-wear conditions (for example, textile manufacturing uses ceramic eyelets and thread guides because of their wear resistance). In the realm of foundry and casting, 3D printed ceramic molds and cores (as mentioned for aerospace) are equally useful for industrial castings of complex metal parts, saving time on tooling and allowing geometries that improve the final product. Because no tooling is needed, low-volume and replacement parts can be produced on-demand – for example, an obsolete mixer blade lining or a custom ceramic bracket can be printed from a CAD model, enabling maintenance of industrial equipment without waiting months for a machined ceramic.

In summary, technical ceramics are truly cross-cutting materials. From aerospace labs to operating rooms, their applications span any field that needs materials to perform in extremes of heat, wear, or bio-compatibility 3dprintingindustry.com. The advent of ceramic 3D printing is accelerating developments in all these industries by providing a fast, flexible way to deploy ceramics’ advantages in complex, customized designs.

Advantages and Limitations

Advantages of 3D Printed Technical Ceramics: By marrying advanced ceramics with additive manufacturing, we gain a combination of material benefits and design freedoms. Key advantages include:

- Exceptional Performance in Extreme Conditions: Technical ceramics already offer superior hardness, temperature stability, and corrosion resistance. 3D printing simply allows those properties to be harnessed in more efficient shapes. A ceramic part can survive where metal or plastic fails – for example, printed ceramics retain strength at red-hot temperatures “far exceeding what metals or polymers can tolerate” wundermold.com, making them invaluable for hot sections of engines, high-wear surfaces, or corrosive chemical environments. They also don’t rust or degrade easily, ensuring long service life (a big plus for anything from biomedical implants to downhole oil-and-gas tools).

- Complex Geometries and Customization: Perhaps the greatest advantage is the design freedom introduced. Without needing molds or cutting tools, intricate internal channels, lattice structures for lightweighting, and patient-specific or mission-specific shapes are all possible. This means engineers can optimize parts for performance – e.g. lattice structures to reduce weight or tailored internal cooling passages in a turbine blade mold lithoz.com, tctmagazine.com. Custom one-off components (like an implant made from a patient’s CT scan) become economically feasible. As one industry expert noted, 3D printing methods can even “enhance the properties of ceramics” by enabling designs that improve how the ceramic behaves (for instance, distributing stress more evenly or achieving previously unachievable small features) 3dprintingindustry.com.

- Rapid Prototyping and Shorter Development Cycles: Additive manufacturing significantly cuts down lead times. Traditional ceramic part development could take months or years (including making molds and multiple machining iterations) tctmagazine.com. In contrast, a design can be printed in days or weeks and tested immediately. Honeywell’s experience is telling: instead of 1–2 years for new cast turbine blades, they 3D printed ceramic molds and got test blades in under 2 months tctmagazine.com. Iterating on a design is as simple as tweaking the CAD file and printing again, rather than retooling an entire production line. This agility is especially advantageous in aerospace and medtech, where development timelines and innovation go hand in hand.

- No Tooling and Lower Waste: Since 3D printing builds parts directly from a digital model, expensive tooling (molds or dies) is eliminated tctmagazine.com, lithoz.com. This not only reduces cost for low to medium production volumes but also enables economically producing geometries that were impossible to mold. Additionally, many ceramic AM processes are relatively material-efficient – unused powder can be recycled in binder jetting, and extrusion/paste printing uses just the material needed. This can lead to less material waste than subtractive machining of ceramics, which grinds away a lot of material and often ends up discarding cracked attempts. The sustainability factor improves as well: producing only what you need, where you need it (since digital designs can be sent to printers globally), potentially reduces the carbon footprint associated with shipping or overproducing spare parts.

- Mechanical, Thermal, and Chemical Benefits: The printed parts inherit the innate advantages of advanced ceramics: extreme hardness and wear resistance (great for cutting tools and bearings), high compressive strength, and often a lower density than metals (for instance, silicon nitride parts are strong yet much lighter than steel). They can also be good electrical insulators – useful for printing custom high-voltage components or antenna substrates. Some ceramics like aluminum nitride offer high thermal conductivity, so a printed AlN heatsink could effectively cool electronics while being insulating electrically wundermold.com. Biocompatibility is another plus in cases like zirconia or hydroxyapatite; printed implants won’t corrode or cause reactions in the body the way some metals might.

Despite these advantages, there are still limitations and challenges to address with ceramic 3D printing:

- Brittleness and Fracture Risk: All ceramics are brittle to some degree – they lack ductility and can fracture under shock or tensile loads. This fundamental material limitation means designers must account for stress concentrations and avoid designs where a ceramic part would experience high tension or impact. While certain formulations like zirconia are tougher, they’re still nowhere near metals in terms of ductility. Researchers are actively working on improving the fracture toughness of printed ceramics and even aiming for “improved ductility” by adjusting microstructures azom.com. But until such breakthroughs arrive, the brittleness means that, for example, a ceramic part may need protective design features (like fillets to reduce sharp corners) or may not be suitable for highly dynamic load scenarios.

- Shrinkage and Warping: As mentioned, the sintering step causes significant shrinkage (often 15-30% by volume), and this can introduce warping or dimensional inaccuracies if not perfectly uniform. Achieving tight tolerances is difficult – typically a printed ceramic part might shrink unpredictably, requiring calibration or even iterative scaling of the print to end up with the right final size. Warping or distortion is especially problematic for larger parts or uneven geometries. Innovations like using special inorganic binders can help reduce shrinkage by leaving an ash or reacting to form a stable phase mdpi.com, but this adds complexity. Cracking can also occur during debinding/sintering if the heating schedule is not carefully controlled to burn off binders slowly and evenly mdpi.com. Thus, the yield of perfect parts can be an issue – some prints might crack in the furnace, reducing overall process efficiency.

- Surface Finish and Precision: While processes like SLA and inkjet offer very fine resolution, others like binder jetting and extrusion yield rougher surfaces and less detail. A binder jetted ceramic part often has a grainy texture and requires post-print sintering that can round off edges. Achieving a smooth, high-precision surface may require post-process grinding or polishing, which is labor-intensive (ceramics can only be machined with diamond tools typically). Small features might also be lost or distorted after sintering if they are below the resolution limit or too delicate to survive binder removal. Supports in SLA printing can leave blemishes that need removal. Therefore, for applications needing ultra-fine precision or a mirror finish (say, certain optical components), additional finishing steps are often needed, which adds time and cost.

- Equipment and Production Costs: The cutting-edge nature of ceramic 3D printing means equipment can be expensive. Industrial ceramic printers (SLA, inkjet) and furnaces capable of high temps are a significant investment, often limiting this technology to specialized companies or research labs. As noted, a ceramic SLA machine can cost hundreds of thousands of dollars aniwaa.com. Material costs are also non-trivial: ceramic powders must be very fine and of high purity, and in the case of proprietary resins or binders, they can be costly per kilogram. Additionally, production rates are not yet as fast as some traditional methods for large volumes – 3D printing is typically suited for prototypes or small batch production, while mass-producing millions of simple ceramic parts (like spark plug insulators) might still be cheaper with traditional pressing and firing. However, these economics are changing as printers become faster and more companies adopt ceramic AM, driving costs down.

- Knowledge and Design Constraints: Designing for ceramic AM requires expertise. Not all shapes that can be printed in polymer or metal are feasible in ceramics due to the post-fire shrinkage and support needs. For instance, printing a fully enclosed hollow sphere in ceramic is problematic because the loose support material inside can’t be removed and the part would likely crack on firing due to internal stresses. Engineers must consider where to place support structures (especially in SLA) and how the geometry will behave during sintering. There’s also the challenge of parameter optimization – each ceramic material might require tweaking layer thickness, cure depth (for SLA), extrusion speed, or binder saturation to get good results 3dprintingindustry.com. The field is still developing best practices, and there is less accumulated know-how compared to metal or polymer AM. Thus, a learning curve exists for new adopters.

In summary, 3D printing is unlocking the tremendous benefits of technical ceramics – enabling high-performance parts with complex designs – but it comes with its own set of limitations. Current constraints include the inherent brittleness of ceramics, the difficulty of achieving perfect accuracy due to shrinkage, surface finish challenges, and the high cost and skill required. Many of these challenges are actively being addressed through research and industry innovation. As the technology matures, we expect to see improved processes (e.g. in-situ monitoring to manage shrinkage, or new binders to increase strength) that will mitigate these limitations and further broaden the use of ceramic AM.

Recent Innovations and News (2024–2025)

The past two years have seen significant breakthroughs in ceramic 3D printing, with companies and researchers pushing the boundaries of what’s possible. Here are some highlights of recent advancements, announcements, and research (2024–2025):

- Jet Engine Prototyping – Honeywell’s 3D Printed Turbine Blade Molds (2024): In May 2024, Honeywell Aerospace revealed that it is using 3D printed ceramic molds to manufacture next-generation turbofan engine blades tctmagazine.com. Turbine blades typically require complex ceramic investment-casting cores and molds, which traditionally take up to 1–2 years to develop. By contrast, Honeywell used a vat-photopolymerization ceramic printer (Prodways’ MOVINGLight technology) to print these molds directly in a high-resolution ceramic resin tctmagazine.com. This slashed the prototype production cycle to just 7–8 weeks, allowing far faster testing and iteration tctmagazine.com. Mike Baldwin, a Principal R&D Scientist at Honeywell, highlighted that additive manufacturing let them go “from design, print the mold, cast it, test it” in a matter of weeks, and then quickly tweak the design and print another – a process that saves potentially millions of dollars in development costs tctmagazine.com. This is one of the first known cases of a major jet engine manufacturer leveraging ceramic AM for critical engine hardware. It demonstrates how 3D printing is transforming aerospace R&D, and it underscores the confidence that the printed molds met the stringent quality needed for casting superalloys tctmagazine.com.

- Industry Partnerships for Scale – SINTX and Prodways (2024): In another 2024 development, advanced ceramics company SINTX Technologies announced a partnership with 3D printer manufacturer Prodways to create a “comprehensive solution” for ceramic 3D printing, especially in casting applications 3dprintingindustry.com. Under this collaboration, SINTX provides its expertise in ceramic materials (they’ve developed multiple printable ceramic resins and powders) to Prodways and its customers 3dprintingindustry.com. Ann Kutsch, General Manager of SINTX’s Maryland facility, noted their team has 6 years of experience with Prodways printers and has already commercialized multiple resin compositions and designs; she expects that a formal partnership “will lead to some breakthrough developments and novel solutions” for customers 3dprintingindustry.com. Notably, SINTX has moved from prototyping into actual production – as of 2024 they offer 3D printed components in alumina, zirconia, and silica ceramics, and even secured a multi-year supply agreement with a major aerospace company 3dprintingindustry.com. This partnership exemplifies how the industry is organizing itself: printer manufacturers teaming up with materials specialists to ensure end-users have a full workflow (materials, process parameters, and support) to successfully adopt ceramic AM.

- AI and Automation – 3DCeram’s “CERIA” System (2025): French company 3DCeram, a pioneer in ceramic SLA printers, introduced an AI-driven process control system named CERIA in 2025. According to reports, the CERIA AI solution is increasing the yield and scale of ceramic 3D printing, by automatically adjusting print parameters and detecting issues in real-time voxelmatters.com. Large-scale industrial ceramic production has been tricky due to variability in prints and sintering outcomes; an AI monitoring solution can significantly reduce errors (like prints that would warp or fail) and optimize the entire production line. This push toward automation and smart manufacturing is aimed at moving ceramic AM from a niche prototyping tool to a reliable mass production technique. By integrating AI, 3DCeram’s goal is to achieve consistent, high-quality output even as part sizes and volumes increase, which is a “new era” for ceramic 3D printing as described in industry news voxelmatters.com.

- Conferences and Collaboration – AM Ceramics 2025 (Vienna): The AM Ceramics 2025 conference, held in Vienna in October 2025, highlighted the rapid progress and growing interest in the field 3dprintingindustry.com. Organized by Lithoz (a leading ceramic printer company), it gathered experts from research and industry to share breakthroughs. Notably, the agenda featured talks on bridging traditional casting with AM (Safran Tech discussed how printed ceramics could reshape aerospace casting methods), on new materials like 3D printed fused silica glass (by Glassomer), and on miniaturized high-precision ceramic components for quantum technology (Ferdinand-Braun-Institut) 3dprintingindustry.com. Even CERN presented on using 3D printed ceramics for thermal management in particle detectors 3dprintingindustry.com. Lithoz CEO Dr. Johannes Homa opened the event by celebrating the industry’s growth: “It’s truly amazing to see the ceramic 3D printing industry grow, driven by so many brilliant minds, each of them rewriting the rules of ceramics” 3dprintingindustry.com. This sentiment underscores the collaborative atmosphere – academia and industry are coming together to solve challenges like scaling up production, improving materials (there was talk of novel ceramic composites), and expanding applications from aerospace labs to medical operating rooms 3dprintingindustry.com. The conference’s 10th edition being held at TU Wien also signals how far ceramic AM has come in a decade, evolving from a curiosity to a dynamic field with its own dedicated forum.

- Research Breakthroughs – Origami Ceramics and Biomedical Advances: On the research front, universities have reported creative advances. For instance, a University of Houston team (2024) developed an “origami-inspired” approach to 3D print foldable ceramic structures that can bend without breaking – a remarkable development given ceramics’ brittlenessuh.edusciencedaily.com. By using a Miura-ori origami pattern in the print design, they showed a ceramic structure could flex under pressure, hinting at future ceramic components with enhanced toughness or shock absorption. In biomedical research, a Caltech/U. of Utah team demonstrated a form of ultrasound-guided in-vivo printing (2025) – while not printing a ceramic per se, they envision it could one day deposit hydroxyapatite or other bioceramics directly at an injury site inside the body ceramics.org. And in the realm of bone tissue engineering, researchers in Australia and China have used digital light processing (DLP) printers to create ceramic bone scaffolds with gyroid lattices and even composite bioglasses, aiming to treat challenging bone defects ceramics.org. These developments underline that ceramic AM isn’t just about aerospace and industry – it’s poised to impact healthcare in life-changing ways as well.

- Commercial Product Launches: Several companies have released new ceramic 3D printers or materials in the last two years. For example, AON Co. (Korea) launched the ZIPRO printer in late 2023, focusing on high-precision dental and jewelry ceramics aniwaa.com. Formlabs (known for polymer printers) entered the ceramic space by acquiring Admatec and releasing an updated Admaflex 130 printer, broadening access to ceramic DLP printing. Materials startups have also introduced improved ceramic resins – Tethon 3D, for example, rolled out new formulations of ceramic photopolymer resin in 2024, allowing common SLA printers to create ceramic parts after a sintering step. Meanwhile, XJet announced progress on functional ceramic electronics; a joint research with XJet’s NanoParticle Jetting demonstrated a 3D printed dual-band antenna that operates at unprecedented 5G frequencies, showcasing the capability of ceramics in high-frequency tech xjet3d.com. These product and material releases indicate a maturing market: more players are offering solutions, and established AM companies are investing in ceramics as a growth area.

Overall, 2024–2025 has been an exciting period for technical ceramics in additive manufacturing. We’ve seen faster prototyping in aerospace, new partnerships and scaling efforts, smarter automation with AI, and a steady stream of innovations from academia. Importantly, the industry is moving beyond small R&D teams – big names in aerospace (Honeywell, Safran), medical (SINTX), and industrial sectors are publicly adopting ceramic 3D printing. This momentum is building confidence that ceramic AM will play a significant role in mainstream manufacturing in the years ahead.

(For further reading and source details: see the Honeywell story in TCT Magazine tctmagazine.com, the SINTX partnership news on 3DPrintingIndustry 3dprintingindustry.com, and coverage of AM Ceramics 2025 3dprintingindustry.com, among other references.)

Expert Commentary

Leaders in the field of technical ceramics and additive manufacturing have expressed enthusiasm about the transformative impact of 3D printing on this once-traditional domain. Here are a few insightful quotes from industry experts and researchers:

- Dr. Johannes Homa, CEO of Lithoz (ceramic 3D printing pioneer): At the AM Ceramics 2025 conference, Dr. Homa reflected on the growth of the industry over the past decade. “It’s truly amazing to see the ceramic 3D printing industry grow, driven by so many brilliant minds, each of them rewriting the rules of ceramics,” he said, highlighting how contributions from researchers and companies worldwide have turned what was a novel technique into a robust, cutting-edge field 3dprintingindustry.com. He noted that the conference evolved into a thought-leadership platform, indicating that ceramic AM now has a strong community pushing it forward. This comment underscores the collaborative innovation happening – materials scientists, engineers, and industry players are collectively challenging old limits of ceramics (like shape and toughness) and finding new applications through 3D printing.

- Mike Baldwin, Principal R&D Scientist at Honeywell Aerospace: Discussing the company’s use of 3D printed ceramic molds for turbine blades, Baldwin emphasized the game-changing effect on development speed. “With the conventional investment casting process, it can take 1–2 years to produce the turbine blades needed for the development process,” he explained, whereas with 3D printing, they could design, print, cast and test within two months tctmagazine.com. If a design change is needed, “we can change it electronically and get another blade in about six weeks,” Baldwin said tctmagazine.com. This quote speaks to the flexibility and agility that additive manufacturing brings. For an engineer, being able to iterate hardware as fast as you can iterate a CAD model is revolutionary – it removes long waits and allows rapid convergence on the best design. Baldwin also mentioned saving potentially “several million dollars” in development costs through this approach tctmagazine.com, pointing out that beyond the technical merits, there’s a strong business case for ceramic AM in high-value applications.

- Ann Kutsch, General Manager, SINTX Technologies (bioceramics expert): On forming a partnership with Prodways, Ann Kutsch highlighted SINTX’s deep experience in ceramic printing and optimism for breakthroughs. “Our outstanding engineering team has 6 years of experience working with Prodways printers… I expect that a more formal partnership will lead to some breakthrough developments and novel solutions for all our customers,” she said in a press release 3dprintingindustry.com. Kutsch’s perspective reveals how companies are now pooling expertise to tackle the remaining challenges in ceramic AM (like scaling up and entering new markets). As a specialist in medical and technical ceramics, SINTX sees 3D printing as a way to commercialize new materials and designs that were previously on the lab bench. Her use of “breakthrough developments” suggests we can anticipate significant technical improvements and application-specific solutions emerging from such collaborations.

- Boris Dyatkin, Materials Research Engineer, U.S. Naval Research Laboratory: From the R&D side, Dr. Dyatkin offered a materials scientist’s view on why 3D printing is so valuable for ceramics. By using a 3D printer, “you’re basically getting more customization in terms of what kind of a ceramic you can make,” he explained in an interview aerospaceamerica.aiaa.org. He was referring to NRL’s work on printing refractory carbide ceramics for hypersonic vehicles, where printing allowed them to create shapes not possible with traditional pressing methods aerospaceamerica.aiaa.org. This quote captures a key sentiment in the research community: additive manufacturing isn’t just replicating what was done before, it’s enabling entirely new types of ceramic components. Scientists can now design microstructures, compositional gradients, or complex geometries and actually fabricate them, which opens up new research pathways in ceramic science. Dyatkin’s comment also hints at the ability to rapidly adjust or tune the composition (for instance, printing different ceramic-metal mixes) much more easily than with conventional processes.

- Vincent Poirier, CEO of Novadditive (ceramic service bureau): In an interview about the transformative impact of 3D printing on ceramics, Vincent Poirier noted that additive processes can “enhance the properties of ceramics” by enabling designs with complex geometries and smaller feature sizes that were previously unattainable 3dprintingindustry.com. He gave examples of how a properly designed 3D printed ceramic part can outperform a traditionally made one – for instance, internal lattice structures can make a part lighter yet maintain strength, or custom cooling channels can keep a part cooler in service, extending its life. Poirier’s company works with dental and industrial clients, and he highlighted that while 3D printing of ceramics is not exactly cheap yet, it provides value in performance that often justifies the cost ceitec.eu. This point of view, from someone offering ceramic AM services, reinforces that the technology’s adoption is being driven by the unique solutions it provides rather than cost alone. As the technology matures, costs will come down, but even now, when faced with an engineering problem that only a ceramic can solve, 3D printing may be the only practical way to get the precise part needed.

Collectively, these expert voices paint a picture of a field on the rise: there’s excitement about the new design freedom and problem-solving capabilities that ceramic 3D printing brings. Industry leaders are seeing real economic and technical benefits, researchers are enthusiastic about pushing materials frontiers, and the community is actively sharing knowledge to overcome remaining challenges. The phrase “rewriting the rules of ceramics” that Dr. Homa used is quite apt – additive manufacturing is changing how we think about designing with ceramics, and these experts underscore that a new era for technical ceramics is just beginning.

Future Outlook

The future of 3D printing in technical ceramics looks extremely promising, with expectations of continued growth, technological improvements, and wider adoption across industries. As we peer into the next 5–10 years, here are some anticipated developments and potential disruptions in this space:

- Scaling Up and Industrialization: One major trend will be scaling ceramic AM from prototype and small batch production into true industrial manufacturing. This means faster printers, bigger build volumes, and automated workflows. We’re already seeing steps in this direction with AI-driven process control (like 3DCeram’s CERIA) and conferences emphasizing scaling from pilot to production voxelmatters.com. By 2025 and beyond, expect printers that can produce larger ceramic parts (e.g. entire multi-cm turbine components or large insulator shapes) reliably. Companies like Lithoz have introduced larger-format machines (e.g. the CeraMax Vario V900 for big parts) and multi-material printers lithoz.com. The introduction of robotics for handling parts through debinding and sintering could also improve throughput. Ultimately, the vision is a ceramic “print farm” churning out high-performance parts much like plastic parts are printed today – and some experts believe we will get there as process stability and speed improve.

- Materials Innovation – Beyond the Classics: We will likely see an expansion of available materials, including more composite and functional ceramics. Research is ongoing into ceramic matrix composites (CMCs) that can be printed, combining ceramics with fibers for extreme toughness (useful in aerospace engines). Another area is functionally graded materials – for instance, a part that transitions from one ceramic to another or ceramic to metal across its volume. Additive methods uniquely allow such gradation by varying the material feed during the build. By 2030, we might have printers capable of printing a part that has a metal core and a ceramic surface, or a gradient from alumina to zirconia, to capitalize on each section’s properties. Glass and ceramic convergence is another frontier: technologies like Glassomer’s printed glass (which is essentially silica, a ceramic) hint that future machines might print optical glass components with high precision 3dprintingindustry.com, opening applications in optics and photonics. In electronics, printable high-permittivity ceramics or piezoelectric ceramics could enable on-demand manufacturing of sensors and circuit components. All these material innovations will broaden the horizons of what ceramic AM can do.

- Improved Mechanical Properties: A critical research goal is to overcome the traditional brittleness of ceramics. While ceramics will never behave like ductile metals, there are strategies to make them more damage-tolerant. Nano-engineered microstructures, whisker or fiber reinforcement, and new sintering techniques (like spark plasma sintering or microwave sintering) could be applied to printed parts to enhance toughness. The University of Houston’s origami ceramics research, where geometric folding imparted flexibility sciencedaily.com, is one creative approach. Another approach is using nanoparticle binding – smaller particles can sinter at lower temperatures, potentially reducing shrinkage and defects. In fact, experts are optimistic: as one report noted, researchers are working to achieve “higher bond energy and improved ductility” in advanced ceramics to expand their structural use azom.com. If in the future a printed ceramic can deform slightly instead of shattering (even if it’s through engineered micro-cracks or internal structures that absorb energy), it would be a game-changer – suddenly ceramics could be trusted in critical load-bearing applications like car engines or infrastructure components without fear of sudden failure.

- Cost Reduction and Accessibility: With growing adoption, the cost of ceramic printing is expected to decrease. More competition among printer manufacturers (we’ve seen entrants from France, Austria, Israel, China, etc.) and materials suppliers will drive down prices of machines and consumables. This will make the technology accessible to more companies, including mid-sized manufacturers and research labs. Some desktop-level solutions might emerge – for instance, specialized filaments or resin kits that let standard 3D printers create ceramic parts (similar to how some labs hack consumer printers for ceramics today). As costs drop, education and training will also improve, spreading the know-how to a new generation of engineers. We may see university courses dedicated to ceramic AM design principles, which will produce more talent in the field, further accelerating innovation.

- Integration with Traditional Manufacturing: Rather than completely replacing conventional ceramic forming methods, 3D printing will integrate with them. A likely scenario is hybrid processes – for example, using 3D printed ceramic cores inside traditionally cast parts, or printing a complex section of a part that is then co-fired onto a larger traditionally made body. Another example is repair: rather than making a whole new part, a damaged ceramic component could be partially printed onto to rebuild missing sections (there is research on direct-write repair of ceramics). In casting, we expect more foundries to adopt printed ceramic molds, as Honeywell did, which disrupts the tooling approach but still uses traditional casting for the metal. This hybridization allows established industries to incrementally adopt AM without overhauling everything. It’s akin to how metal AM is used to make molds for injection molding plastic parts – in ceramics, printed cores and molds will become common in foundries and for producing complex shapes that then join with simpler ceramic pieces.

- New Applications and Market Growth: As the technology matures, entirely new applications for technical ceramics will emerge, some perhaps in consumer markets. One could imagine bespoke luxury goods – e.g. custom 3D printed ceramic watch cases or jewelry with intricate lattice aesthetics (ceramics can be very beautiful and are skin-friendly). The electronics miniaturization trend might spur demand for 3D printed ceramic substrates with embedded circuits for wearables or IoT devices that need to withstand heat or biofluids. In the medical sphere, patient-specific implants (like cranial or jaw implants) could be printed on-site at hospitals if regulatory frameworks allow – the first steps in this direction are already being taken with metal implants, and ceramics may follow for certain indications. Defense and aerospace will continue to drive development of ultra-high-temperature materials for hypersonics – by 2030, it’s conceivable that some hypersonic vehicles or re-entry spacecraft will have critical 3D printed ceramic components (like leading edge tiles or engine liners) because only those can meet the extreme requirements. Market analysts are bullish: the overall additive manufacturing market is growing steadily (expected to hit tens of billions of dollars in the mid-2020s), and the ceramic AM segment is forecasted to experience strong growth as part of that, as more end-users discover the value it provides.

- Potential Disruptions – Speed and New Processes: A wild card in the future is the development of radically faster or different ceramic printing processes. For example, a form of direct laser sintering of ceramics: if a breakthrough occurs that allows a laser or electron beam to sinter ceramic powder rapidly without cracks, that could enable one-step ceramic printing (similar to how metals are printed today with laser powder bed fusion). There’s also research on cold sintering (using pressure + moderate heat + additives to sinter quickly) which, if applied to printed parts, might cut down furnace times from hours to minutes. Another area is in-situ printing – for instance, printing ceramics directly onto existing assemblies (printing a ceramic insulation layer onto a metal part). The ultrasound in-vivo printing concept from Caltech ceramics.org is far-off, but conceptually, being able to fabricate ceramic structures on demand in place (even inside the body or in space) is a paradigm shift. The first adopters of any new process will likely be high-value sectors like aerospace or medical.

In conclusion, the trajectory of 3D printed technical ceramics points toward far greater impact on technology and manufacturing than we’ve seen to date. As one materials expert noted, advanced ceramics are “expected to play a crucial role in shaping the future of technology” across many sectors azom.com. Additive manufacturing is the key that is unlocking this potential. In the coming years, we can expect technical ceramic parts – from tiny electronic components to large engine parts – to be designed in ways never before possible and produced on demand. The combination of ceramics’ superior properties with the flexibility of 3D printing will continue to yield innovations that solve engineering challenges and enable new products. We are witnessing the early stages of a ceramic revolution in manufacturing: one where age-old ceramic materials meet 21st-century digital fabrication, resulting in a powerful synergy that will drive progress in aerospace, energy, healthcare, electronics, and beyond. The excitement from industry leaders and researchers is a clear sign – the best in ceramic 3D printing is yet to come. 3dprintingindustry.com, azom.com