Imagine having a living digital copy of a city, a factory, or even yourself. This is the promise of digital twin technology, a rapidly growing field projected to reach a global market of $73.5 billion by 2027 mckinsey.com. In essence, a digital twin is a virtual replica of a physical object or system, continuously updated with real-world data to mirror its behavior and state mckinsey.com. By linking real-world sensors and data streams to immersive 3D models, digital twins enable organizations to simulate scenarios, predict outcomes, and optimize decisions in ways never before possible. From manufacturing plants and hospitals to entire smart cities and even the human body, digital twins are revolutionizing industries and blurring the line between physical and digital realms. This report provides a comprehensive overview of digital twin technology – what it is, how it evolved, its core components, applications across sectors, key benefits, challenges, and the latest trends and breakthroughs as of 2024–2025.

What is a Digital Twin?

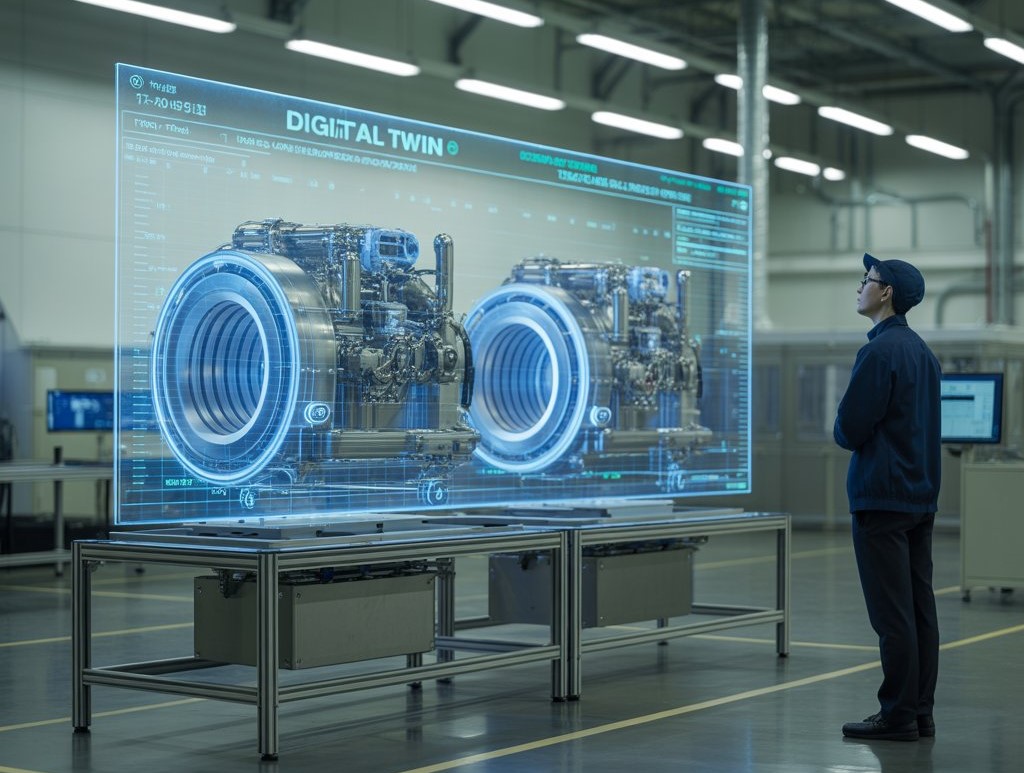

A digital twin is essentially a digital replica of a real-world entity – be it a machine, person, process, or even an entire ecosystem – that is kept in sync with the original through real-time data info.expeditors.com, mckinsey.com. Put simply, it’s a virtual model that mirrors a physical “twin”. Unlike a static simulation or CAD model, a digital twin stays continuously updated via sensors and IoT feeds, reflecting changes in the physical object’s condition or environment in real time mckinsey.com. This live linkage means the digital twin can be used to test “what-if” scenarios, perform simulations, monitor performance, and even control the physical asset with a high degree of accuracy.

Illustration of a digital twin: an aircraft’s physical model (left) and its real-time digital replica (right) with data connectivity mckinsey.com.

Core Components: By definition, every digital twin setup involves three fundamental parts simio.com:

- Physical Object or Process: The real-world thing (e.g., a jet engine, a building, a patient) along with its operating environment.

- Digital Representation: A detailed virtual model of that physical entity, capturing its structure, context, and behavior.

- Data Connection (Digital Thread): The communication channel that streams data between the physical and digital counterparts (often via sensors, IoT devices, networks) to keep them synchronized simio.com, en.wikipedia.org.

Through this continuous data flow, the digital twin updates as the physical object changes, and in advanced cases, control signals can also feed back from the twin to the original. In practice, creating a digital twin involves instrumenting the physical asset with sensors, building a high-fidelity virtual model (using CAD, 3D scanning, etc.), and integrating analytics or AI to interpret the data research.aimultiple.com. For example, engineers might attach IoT sensors to a factory machine to collect temperature, vibration, and performance metrics, stream these to a cloud-based simulation model, and apply AI algorithms to predict failures or optimize operations research.aimultiple.com. The result is a “living” model that behaves like the real thing.

How Digital Twins Work: In operation, a digital twin continuously ingests real-time data (e.g. sensor readings, operational logs, environmental conditions) from its physical twin bradley.com. This data drives the virtual model, enabling it to emulate the current state of the physical system at any moment. Analysts or AI systems can then interact with the twin – run simulations, test adjustments, or monitor performance – with the confidence that the twin accurately reflects reality. Insights gained (say, a predicted part failure in 10 days) can be applied back to the physical asset (e.g. schedule maintenance now). In short, the twin provides a safe, virtual testing ground for changes that would be risky or costly to try on the real asset bradley.com. For instance, doctors could experiment on a heart’s digital twin to see how it responds to a new drug without any risk to the patient bradley.com. This feedback loop between physical and digital – often called the “digital thread” – is what makes digital twins so powerful.

The Evolution of the Digital Twin Concept

Though it feels like an ultra-modern idea, the roots of digital twin technology stretch back decades. NASA’s Apollo program in the 1960s foreshadowed the concept when engineers on Earth built full-scale physical replicas of spacecraft to troubleshoot issues remotely – a lifesaving strategy famously used during the Apollo 13 crisis info.expeditors.com. In essence, those were early “twins,” albeit physical and analog. The broader vision of a software-based twin was articulated in computer scientist David Gelernter’s 1991 book Mirror Worlds, which imagined detailed digital models mirroring real-world systems via continuous data streams simio.com.

The term “digital twin” itself came into being around the turn of the millennium. Often credited is Dr. Michael Grieves, who in 2002 formally presented the idea of a digital representation linked to a physical product throughout its lifecycle simio.com. Around the same time at NASA, technologist John Vickers and colleagues began using “digital twin” to describe next-generation spacecraft simulations (NASA provided the first practical definition in 2010 aimed at improving spacecraft modeling) en.wikipedia.org, info.expeditors.com. In those early 2000s, only a few forward-thinking organizations experimented with the concept, as the necessary data couldn’t be easily gathered or processed with the tech available then gray.com.

Enabling Technologies: The 2010s saw a convergence of innovations that propelled digital twins from theory to mainstream. The explosion of the Internet of Things (IoT) made it feasible to instrument virtually anything with cheap sensors and connect them via the cloud, providing the live data fuel that twins require simio.com. At the same time, advances in big data storage and cloud computing meant that the deluge of data from physical assets could be stored and analyzed at scale simio.com. By the late 2010s, industry leaders like General Electric, Siemens, and IBM had begun building digital twin platforms, and analyst firm Gartner named digital twins among the Top 10 Strategic Technology Trends of 2019 info.expeditors.com. The World Economic Forum noted by 2015 that digital twins were transitioning from a niche concept to a “mainstream industrial technology” across sectors simio.comsimio.com.

During the 2020s, the evolution continued rapidly. Early implementations were essentially static or one-way models (sometimes called “digital shadows”, which only reflected the physical state) simio.com. Now, we have fully interactive twins with two-way data flow – the digital twin not only receives data but can send optimized instructions back to the physical asset, creating a closed-loop system for real-time control simio.com. Industry experts outline a maturity curve in five stages: from simple Mirroring of objects, to Monitoring their status, to advanced Modeling/Simulation, then Federation of multiple twins, and ultimately Autonomous twins that can self-optimize without human input simio.com. As of 2025, many sectors are entering the latter stages, with digital twins becoming dynamic, AI-driven systems. One tech research firm predicted that “by 2025, digital twins will transform into dynamic, adaptive, and predictive models, driven by advancements in AI, IoT, and real-time data” simio.com.

In summary, what began as rudimentary simulators and CAD models has evolved into sophisticated, intelligent virtual replicas. From NASA’s physical duplicates to today’s cloud-powered industrial metaverse, digital twin technology has come a long way. Dr. Grieves’ early formulation laid out the same three core elements we still use simio.com, and those remain the foundation even as we layer on AI, AR/VR visualization, and other bells and whistles. The stage is set for digital twins to be ubiquitous in design, operations, and decision-making processes across the economy.

Applications Across Industries

One reason digital twins are generating so much buzz is their versatility – they can model virtually anything. Here’s how this technology is being applied (as of 2024–2025) in various industries:

Manufacturing & Industrial Engineering

In manufacturing, digital twins lie at the heart of the Industry 4.0 revolution. Factories create digital twins of everything from individual machine components to entire production lines. This allows them to simulate and optimize processes in a virtual space before implementing changes on the shop floor. For example, assembly line configurations can be tested in the twin to maximize throughput, and robotic workflows can be fine-tuned virtually. The benefits have been tangible: Gartner predicts a 10% improvement in overall industrial efficiency via digital twin adoption, thanks to reductions in unplanned downtime and better performance tuning research.aimultiple.com. A Deloitte case study noted that a manufacturer using a production line twin managed to cut changeover time by 21% by simulating different scheduling and layout scenarios gray.com.

Product Design and Prototyping: Engineers use product twins as “living prototypes.” Rather than building and testing numerous physical prototypes, companies can run design iterations on the digital twin to see how a product behaves under various conditions. McKinsey found that some R&D teams have cut development cycles by up to 50% by relying on digital twins – dramatically accelerating time to market and lowering costs for testing mckinsey.com. For instance, Boeing’s development of the T-7A Red Hawk jet trainer leveraged digital twin models so extensively that the aircraft went from concept to first flight in only 36 months. Boeing reported astonishing gains: an 80% reduction in assembly hours and 50% less software development time, with first-time quality improving 75%, by using digital twins throughout design and production digitaltwininsider.com. These kinds of results showcase why manufacturers are racing to implement twin technology.

Operations & Maintenance: Once products or equipment are in use, digital twins enable predictive maintenance and operational optimization. Sensors feed the twin data on machine health (vibrations, heat, output levels, etc.), and AI algorithms analyze it to predict failures before they happen. Oil and gas company Chevron, for example, expects to save millions of dollars in maintenance by 2024 by deploying digital twins to anticipate equipment issues in refineries gray.com. Similarly, General Electric has used digital twins for its turbine engines and reported cutting reactive maintenance by 40% while achieving 99.49% reliability in operations digitaltwininsider.com. These improvements translate to huge cost savings and uptime for industrial assets. Additionally, production twins can continually adjust processes – for example, tweaking machine settings to reduce energy consumption or improve quality yield based on the twin’s simulations.

Healthcare & Medicine

The healthcare sector is embracing digital twins in innovative ways, from hospitals to personalized medicine. A hospital might create a digital twin of an entire facility – mapping every ward, bed, staff schedule, and medical device in a virtual model. This “hospital twin” can simulate patient flow, resource usage, and even responses to surges (like a pandemic scenario) to optimize care delivery. It’s estimated that 66% of healthcare executives plan to increase investment in digital twins in the next three years research.aimultiple.com, seeing them as a key tool to improve patient outcomes and efficiency.

Doctors using an interactive digital twin of the human body for surgical planning and training (conceptual example) research.aimultiple.com.

One of the most exciting frontiers is the digital twin of the human body. Researchers are now creating virtual models of organs, or even entire physiologies, for personalized diagnosis and treatment. These patient-specific twins integrate data from medical imaging, vital signs, genetics, and lifestyle factors to mirror an individual’s health state. In concept, a doctor could test how a particular patient’s twin heart responds to a new medication or rehearse a complex surgery on the twin before operating on the real patient bradley.combradley.com. This could greatly reduce risk and trial-and-error in treatment. While fully realized patient twins are still in early stages, progress is underway – for instance, a Swedish university built a digital twin of a mouse’s heart at the cellular RNA level to study drug effects research.aimultiple.com. Medical device companies also use digital twins for designing and testing new devices (like stents or prosthetics) under virtual physiological conditions, speeding up R&D while ensuring safety.

Beyond individuals, digital twins assist in public health and biomedical research. Epidemiologists can model the spread of diseases in a “population twin” to test interventions. And pharmaceutical researchers employ digital twins of biochemical processes to simulate how a drug interacts in the body, potentially reducing the need for as many physical clinical trials. All told, healthcare digital twins promise more predictive, preventive, and personalized medicine, though they also raise new questions about data privacy and medical ethics (addressed later in this report).

Smart Cities & Infrastructure

Entire cities are getting their own digital doppelgängers. Urban planners and local governments use city-scale digital twins to model infrastructure, transportation, utilities, and even demographics in a holistic virtual platform. For example, Orlando, Florida has built a digital twin encompassing 800 square miles of the region, complete with 3D rendered buildings and real-time data overlays xrtoday.com. City officials and citizens can interact with this model on a large screen at the Orlando Economic Partnership’s headquarters to visualize development plans or analyze “what-if” scenarios for traffic, public transit, zoning changes, and more xrtoday.com. The twin updates with live city data (e.g. traffic sensors, climate data, construction projects), allowing planners to foresee the impact of changes in near real time.

Urban Planning: Digital twins of cities are invaluable for testing policies in a risk-free environment. Want to see how adding a new highway or changing a bus route will affect congestion? Feed the data into the city twin and simulate it. Singapore’s government, for instance, has a well-known 3D digital twin of the entire city (Virtual Singapore) used to simulate everything from crowd flows to power consumption in different urban plans. These tools help create smarter, more resilient cities by optimizing layouts and responses to events. A study of academic publications found that “urban spaces and smart cities” accounted for the largest share (47%) of digital twin research use cases, reflecting how prominent this application has become research.aimultiple.com.

Infrastructure Management: Beyond city planning, twins are used for operational management of critical infrastructure. Utility companies maintain digital twins of power grids, water networks, or telecom networks to monitor conditions and quickly isolate problems. If a water main breaks, the twin can simulate rerouting flow to minimize impact. In civil engineering, infrastructure twins of bridges, roads, and tunnels allow continuous structural health monitoring – sensors feed data on strain or vibration into the twin so engineers can spot wear and tear early. For example, Bentley Systems (a leader in infrastructure software) partnered with Google in 2024 to integrate Google’s high-quality 3D geospatial content into Bentley’s digital twin platform, enhancing the realism and context for infrastructure twins technologymagazine.com. This helps planners virtually inspect assets in situ and glean insights like where to prioritize maintenance. The long-term vision is that every “smart city” will have a living digital replica, where administrators can simulate anything from disaster evacuations to new building developments in VR before making real-world moves.

Aerospace & Defense

The aerospace industry was an early adopter of digital twin thinking (dating back to NASA), and today it’s pushing the technology to new heights. Modern aircraft are incredibly complex systems, and manufacturers like Airbus and Boeing now employ digital twins throughout an aircraft’s lifecycle – from design and testing to flight operations and maintenance. As noted, Boeing’s use of digital twins yielded dramatic efficiencies in developing the T-7A trainer jet digitaltwininsider.com. Similarly, Airbus reported saving €201,000 and 1,250 tons of CO2 emissions annually by using digital twins to optimize certain aircraft manufacturing processes digitaltwininsider.com. These savings came from reducing waste and energy usage via simulation-driven tweaks.

Flight Simulations and Training: In operation, every modern jet engine produced by companies like Rolls-Royce or GE comes with its own digital twin. These twins ingest in-flight sensor data (temperatures, pressures, vibrations) and help airlines and militaries perform predictive maintenance on engines – scheduling service only when needed and avoiding catastrophic failures by catching issues early. Space agencies are also using digital twins: for example, NASA creates twins of spacecraft and rovers to rehearse missions virtually and troubleshoot from millions of miles away. The upcoming Artemis program intends to have a detailed digital twin of the lunar Gateway station for remote management.

Defense organizations use digital twins for scenario planning and mission rehearsal. A fighter jet’s twin can be used to test new software upgrades under countless virtual sorties before risking them in a real flight. Even battlefields and entire defense systems (ships, radar networks, etc.) can be twinned to war-game strategies with simulated adversaries. Given the expense and risk of testing in aerospace and defense, digital twins have become indispensable for de-risking innovations and ensuring systems work as intended under all conditions.

Automotive & Transportation

The automotive sector is undergoing a digital twin transformation on multiple fronts – manufacturing, vehicle design, and the driving experience itself. Automakers like Tesla, BMW, and Toyota utilize digital twins extensively in design and production. Virtual car prototypes are subjected to crash tests, aerodynamic modeling, and performance tuning in simulation, reducing the need for numerous physical prototypes. For instance, Toyota used digital twins to refine their assembly line processes and achieved notable savings in energy and cost digitaltwininsider.com. Nissan’s UK plant tripled throughput and saved tens of thousands of dollars by using predictive simulation twins to optimize their powertrain production line digitaltwininsider.com.

Once cars are on the road, manufacturers increasingly keep a digital twin for each vehicle – especially electric and connected vehicles. Tesla famously equips its cars with an array of sensors and IoT connectivity, essentially allowing the company to maintain a digital replica of each car’s state. This enables Tesla to push over-the-air updates, diagnose issues remotely, and even anticipate failures or battery degradation on individual vehicles based on twin data toobler.com. Fleet operators do similarly: for example, some trucking companies use digital twins of their trucks to schedule maintenance at optimal times and simulate route optimizations for fuel efficiency.

Customer Experience: An intriguing automotive application is using digital twins to enhance customer engagement. Mercedes-Benz, for example, has created “customer twins” – virtual models of their vehicles that customers can interact with in immersive showrooms mckinsey.com. Prospective buyers can test-drive a car’s digital twin in VR, customizing features and experiencing the vehicle without a physical test drive. This not only improves the buying experience but also provides Mercedes data on customer preferences and usage patterns via the twin. Going forward, vehicles in the era of autonomous driving will likely have digital twins constantly learning and improving algorithms based on driving data aggregated from many cars. City traffic systems too will integrate with digital twin models – for instance, simulating traffic flow in a digital twin of a road network allows logistics companies to plan optimal delivery routes and adapt to real-time conditions gray.com.

Energy & Utilities

In the energy sector, digital twins are fueling smarter and more sustainable operations. Power generation companies deploy twins of power plants, wind farms, and grid networks to optimize output and maintenance. A wind turbine’s twin can simulate airflow and wear on blades to schedule pre-emptive repairs before a turbine fails (avoiding costly downtime). General Electric’s power division credits digital twin analytics for significant improvements in reliability and cost savings, as mentioned earlier (e.g., $11 million saved by reducing unplanned outages) digitaltwininsider.com.

Electric utilities use grid twins to balance load distribution and quickly isolate faults. For example, a digital twin of an electric grid can run contingency simulations – “If this substation goes down, what rerouting keeps the lights on?” – and thus help engineers respond in seconds to real incidents. Oil & gas companies create twins of their refineries and offshore platforms to monitor conditions and test adjustments that could improve throughput or safety. During the pandemic, some refineries operated semi-remotely via digital twins, with control room operators managing processes from off-site by interacting with the plant’s twin in real time.

Energy companies are also leveraging twins for sustainability goals. Siemens has implemented “digital energy twins” in industrial breweries that reduced energy usage by 15-20% per site and halved CO2 emissions, by continuously tuning operations for efficiency digitaltwininsider.com. On a grander scale, efforts are underway to model environmental systems: NVIDIA’s Earth-2 initiative aims to create a digital twin of the Earth’s climate system, so scientists can simulate climate change scenarios with supercomputers to better predict weather extremes and inform policy gamesbeat.com. Such an Earth-scale twin would integrate massive datasets (satellite imagery, climate physics models) and could be a game-changer for climate research, essentially becoming a planetary “flight simulator” for testing interventions.

From these examples, it’s clear that digital twins have permeated nearly every industry – manufacturing, health, cities, aerospace, automotive, energy, and more. Other notable mentions include retail (stores use twins to model shopper traffic and layout changes), telecommunications (network twins to manage 5G rollout), and even agriculture (farmers using soil and crop twins to optimize yields). Wherever there is valuable physical data to collect and complex systems to optimize, digital twins can likely add value.

Benefits and Value Proposition

Why are so many organizations turning to digital twins? The technology offers a host of compelling benefits and business value drivers:

- Predictive Maintenance & Reduced Downtime: Perhaps the most cited benefit, digital twins enable condition-based maintenance rather than schedule-based. By analyzing real-time performance data, twins help predict equipment failures before they happen, so maintenance can be done just-in-time. This lowers maintenance costs and prevents costly unplanned outages research.aimultiple.com. For example, an aerospace twin might detect subtle vibration anomalies in an engine and prompt a fix that avoids a mid-flight failure. Studies show companies can significantly cut downtime – one global survey found industrial firms improved effectiveness by ~10% via twin-driven predictive maintenance research.aimultiple.com.

- Improved Efficiency and Productivity: Digital twins provide unprecedented visibility into operations, allowing optimizations that boost output and efficiency. By simulating processes under many scenarios, twins help identify bottlenecks and optimal settings. Many organizations report productivity gains of 30–60% after implementing digital twins in production environments simio.com. For instance, tuning a manufacturing line via its twin can reduce cycle times and increase throughput with minimal trial-and-error on the real line. A Schneider Electric client saw 20% cost savings and 50% faster time-to-market by using a machine twin to streamline commissioning and production, while another manufacturer doubled output efficiency and cut energy use by 40% with twin optimizations digitaltwininsider.com.

- Faster Innovation & Time-to-Market: With digital twins, product development and process changes happen much faster. Engineers can iterate designs rapidly in the virtual world. McKinsey notes that some companies have cut R&D cycles in half thanks to digital twins mckinsey.com. Eliminating physical prototyping steps speeds up innovation. Additionally, problems get discovered virtually (and early), reducing costly rework later designnews.com. As Siemens CEO Roland Busch highlighted, digital simulation lets you “set up new production lines or simulate the functions of a human heart” and tweak designs on the fly, avoiding extensive rework and redesigns later on designnews.com. The result is not only speed but improved first-time quality – Boeing’s 75% improvement in first-time engineering quality on the T-7A is a powerful example digitaltwininsider.com.

- Better Decision Making through Simulation: Digital twins serve as high-fidelity testbeds for decision makers. They allow leaders to play out hypothetical scenarios (from minor process changes to major disaster responses) and see likely outcomes, supported by data. This greatly de-risks strategic decisions. A Harvard Business Review piece described how strategic twins let executives run simulations of market or supply chain disruptions and find robust responses deloitte.com. In supply chain management, a twin can mimic the entire logistics network – letting a company experiment with, say, shifting a supplier or rerouting shipments digitally to predict impacts on cost and delivery times before committing in real life mckinsey.com. Some companies have boosted their decision-making speed by 90% using twin-derived insights, since they can evaluate options in days instead of months mckinsey.com.

- Cost Savings and Resource Optimization: Nearly all the above translate to cost savings – through less downtime, less wastage, and more efficient use of resources. Specific examples: Unilever’s factory twin cut false alarms by 90%, reducing interruptions and saving labor digitaltwininsider.com. Mercedes-Benz’s use of virtual factory twins cut construction time for new assembly facilities by 50%, yielding huge savings in capital expenditures digitaltwininsider.com. Twins also help optimize energy and resource usage, contributing to sustainability goals (as seen with Siemens’ energy twin reducing brewery CO2 by 50% digitaltwininsider.com). Even in maintenance, fixing things right on the first try using twin diagnostics saves on spare parts and technician hours.

- Enhanced Customer Experiences: Digital twins can also drive top-line benefits by improving customer engagement and personalization. For example, virtual twins of products allow customers to experience and customize products in immersive ways (like the Mercedes virtual test drive scenario) which can differentiate a brand and boost sales mckinsey.com. In services, having a digital twin of a customer (in terms of their usage patterns or preferences) can help tailor services uniquely to them, increasing satisfaction. McKinsey found organizations using customer twins saw revenue increases up to 10% by delivering more immersive and customized experiences mckinsey.com.

- Resilience and Risk Mitigation: By understanding systems via their twins, companies become more resilient to shocks. A digital twin can expose vulnerabilities in a system (like single points of failure in a supply chain or manufacturing line) so that contingencies can be developed. In operations, twins help maintain stability under a variety of conditions by enabling rapid adjustments. McKinsey notes that digital twins heighten resilience to supply-and-demand shocks, as companies can simulate and prepare for various scenarios (e.g., sudden supplier loss, demand spikes) and thus respond without chaos mckinsey.com.

In summary, the value proposition of digital twins is multi-fold: lower costs, higher uptime, faster development, better quality, and smarter decisions, all contributing to competitive advantage. It essentially gives organizations a crystal ball (through predictive analytics) and a sandbox (for safe experimentation) for their physical operations. As one Siemens expert put it, “Digital twins can keep on collecting data during a product’s operational lifetime… such information supports optimization during operations and aids engineers in preparing the next generation of a product.” gray.com By continuously learning from the real world, the twin helps make both present operations and future designs better.

However, reaping these benefits is not automatic – it comes with challenges and requirements, which we address next.

Challenges, Limitations, and Ethical Considerations

Like any transformative technology, digital twins come with their share of challenges, limitations, and ethical questions. Implementing and using twins is not a trivial endeavor, and organizations must navigate these hurdles:

- Data Management and Quality: A digital twin is only as good as the data it receives. Ensuring high-quality, real-time data from physical assets can be challenging. It requires deploying robust sensor networks and IoT devices, and maintaining them over the asset’s life simio.com. Many older machines weren’t designed to be connected, so retrofitting sensors or integrating disparate data sources is a technical hurdle. Additionally, twins generate massive data streams that must be stored, processed, and analyzed (often in the cloud). Data integration from multiple sources (equipment telemetry, environmental sensors, enterprise systems) can be complex. Poor data (noisy, delayed, or incomplete) can lead to an inaccurate twin and flawed insights. Therefore, companies need strong data governance and perhaps AI techniques to filter and validate twin data.

- Complexity and Cost: Building a high-fidelity digital twin can be resource-intensive. It may require advanced simulation software, 3D modeling, and AI expertise to develop. The upfront cost and effort to create a detailed twin (and the ongoing cost to maintain it and process its data) can be significant, which may deter smaller firms. There’s also the complexity of modeling – not every system is easily modeled in software, especially highly complex, emergent processes. Some critics point out that for extremely complex systems, a fully accurate twin might be practically unattainable or would consume too much computational power to be real-time. Organizations must decide the level of detail needed in a twin (a simplistic model is easier but less insightful, whereas a comprehensive physics-based model can be heavy). Striking the balance is a challenge.

- Privacy Concerns: When digital twins involve human-related data (like patient health data in a medical twin or personal behavior data in a smart city twin), privacy becomes a paramount concern bradley.com. Twins operate by aggregating lots of data, some of it highly sensitive. Modern privacy laws (GDPR in Europe, HIPAA in healthcare, etc.) impose strict rules on data minimization, consent, and the right to delete data. But a digital twin’s value comes from historical data accumulation and detail – there’s a tension here. For example, if a person revokes consent to use their data, does the part of the twin representing them have to be deleted? How do you anonymize a twin that is meant to mirror a specific individual? bradley.com These are thorny issues. City digital twins that use camera data or cellphone data to model crowds must be careful to anonymize and aggregate information to avoid surveillance concerns. Developers must bake privacy protections into twin design (privacy-by-design), ensure proper data consent and transparency, and potentially implement data aggregation that respects individual rights bradley.com. Failure to do so could not only breach laws but also undermine public trust in twin technologies.

- Security Risks: By their nature, digital twins are deeply connected – they bring together operational tech with IT networks and often connect to the internet (cloud platforms). This can expand the attack surface for cyber threats bradley.com. If a hacker were to breach a digital twin system, they might manipulate the data or the model – in worst cases, if the twin has control links back to physical equipment, this could lead to real-world damage. Securing the data flows and twin platforms is thus critical. Twins rely on continuous data transmission from IoT sensors; these devices are notoriously vulnerable if not properly secured (default passwords, etc.). A twin could also inadvertently provide a blueprint of a facility to adversaries if accessed (since it’s a detailed model of how a plant or grid operates). To mitigate this, companies need to implement encryption, stringent access controls, network segmentation for twin systems, and constant monitoring for anomalies (some are even creating “digital twin honeypots” or ghosts to detect intrusions) gray.com. The U.S. Department of Energy and GE have worked on a “digital ghost” cybersecurity system that learns the normal patterns of a network of twins and flags any deviance as a potential cyber intrusion gray.com. This kind of approach will be increasingly important as twins become integral to operations.

- Ethical Dilemmas: Ethics in digital twin use can be quite complex, especially in medical and human contexts. For example, if a healthcare digital twin of your heart discovers a previously unknown serious risk, what is the caregiver’s obligation? Should they inform you even if that wasn’t the original purpose of the twin? bradley.com And if the twin’s data had been anonymized for privacy, could they even trace it back to you to warn you? There are scenarios where a twin might predict something sensitive (like a genetic propensity for a disease) – handling such information responsibly is an open question. There’s also the risk of misuse: because regulations are still catching up, someone might use digital twin data in unethical ways (e.g., an insurer obtaining a health twin to adjust premiums, or an employer monitoring worker twins for productivity in invasive ways). Bias is another concern – if the algorithms driving a twin (say, for a smart city) have bias, it could lead to unjust outcomes (like misallocating resources). Since twins make it easy to individualize treatment or service (“the decontextualization of digital twins” to a single person or thing bradley.com), some ethicists worry this might reduce broader fairness or lead to discrimination if not governed well. Transparency will be crucial – people should know if decisions (medical, financial, etc.) are being informed by a digital twin of them and have some recourse or understanding of that process.

- Interoperability and Standards: With many vendors and platforms creating digital twin solutions (Siemens, Microsoft Azure Digital Twins, IBM, etc.), interoperability is a concern. If each uses proprietary formats, integrating twins from different systems (or transferring a twin model from one platform to another) can be difficult. Efforts like the Digital Twin Consortium are trying to develop standards and best practices to ensure different twin systems can work together or at least speak common data languages. Until standards mature, companies might face vendor lock-in or integration headaches when scaling up digital twin deployments across their enterprise.

- Skill Gaps: Building and leveraging digital twins requires a multidisciplinary skillset – IoT specialists, data scientists, simulation engineers, and domain experts. There is currently a shortage of professionals with experience in this exact convergence. Companies often need to invest in training or rely on consulting experts to get started. As digital twin adoption grows, we will likely see more focus on educating the workforce (universities adding relevant programs, etc.). But in the short term, talent and expertise can be a limiting factor.

Despite these challenges, none are insurmountable. They do, however, require proactive strategies. For instance, robust governance frameworks should be established for any large-scale digital twin initiative – covering data consent, cybersecurity (with continuous threat modeling), and clear guidelines on ethical use of twin insights. Many organizations set up cross-functional teams (IT, legal, operations, etc.) to oversee their digital twin programs to ensure compliance and address risks. As the technology matures, we can also expect regulators to issue clearer guidance on privacy and safety standards for digital twins (much as automotive and medical devices have regulations).

Erin Illman, a tech law expert, noted that digital twin tech “falls squarely into many of the privacy, security, and ethical issues that plague new technologies generally” and urges developers to consider how data rights (like deletion or consent revocation) would work when that data is part of a twin’s knowledge base bradley.com. It’s a call for vigilance: even as we get excited about twins, we must design them responsibly. The bottom line is that digital twins hold immense promise, but building trust in them – for users, consumers, and society – will be key. Addressing privacy, security, and ethics is not just a regulatory box-check; it’s essential to widespread acceptance of these digital doppelgängers in our daily lives.

Current Trends and Emerging Developments (2025 and Beyond)

As of 2025, digital twin technology continues to evolve rapidly, influenced by parallel advances in AI, computing, and connectivity. Here are some of the key trends shaping the digital twin landscape:

- AI-Enhanced Twins (Cognitive Twins): The integration of artificial intelligence and machine learning with digital twins is a dominant trend. AI not only helps analyze the vast data from twins but increasingly allows twins to become predictive and prescriptive. Advanced twins employ machine learning models to predict future states or detect anomalies that humans might miss. We’re also seeing the rise of Generative AI in twins – for example, using generative models to simulate realistic variations of scenarios. McKinsey notes that generative AI can streamline digital twin deployment by auto-generating some of the models or filling in data gaps mckinsey.com. With AI, twins are evolving from reactive monitors to adaptive, self-optimizing systems. An industrial twin might automatically adjust a process in real time to optimize yield, using reinforcement learning. This foreshadows a future of more autonomous twins that require minimal human intervention.

- Convergence with the Metaverse (XR and Immersive Visualization): The buzzwords “industrial metaverse” or “enterprise metaverse” often center on digital twins. Essentially, as AR/VR and 3D visualization tech improve, interacting with digital twins becomes more immersive. Executives can “walk through” a factory’s digital twin in VR or overlay a twin on a physical asset via AR glasses during maintenance. Siemens’s CEO Roland Busch is a strong proponent of this, stating that the industrial metaverse – enabled by digital twins, simulation, and AI – will allow people to perform complex tasks faster and more accurately via immersive environments designnews.com. We see partnerships like Siemens and NVIDIA working together to bring Siemens’ industrial twins into NVIDIA’s Omniverse 3D platform, merging physics-based models with high-fidelity visualization and even connecting to Sony’s AR/VR hardware designnews.com. The trend suggests that in the near future, designing or troubleshooting via a digital twin will feel like a video game – intuitive and visual – which could democratize its use beyond engineers. For instance, at CES 2024, Siemens showcased a prototype metaverse helmet that uses VR to let engineers design a car cockpit in a virtual twin, making the experience interactive and even fun designnews.com. This merging of twins with XR (extended reality) is set to transform training, collaboration, and design processes.

- Scale and Federation of Twins: As adoption grows, organizations are moving from single digital twins to networks of twins. Instead of just a twin of one machine, they build integrated twins of entire production systems or supply chains. This requires standards and interoperable frameworks. The concept of a Digital Twin of an Organization (DTO) is emerging – where a company creates a virtual mirror of not just equipment, but also processes, people, and KPIs, to simulate business outcomes end-to-end research.aimultiple.com. This broadens the twin’s scope from operational tool to strategic tool. We’re also seeing federated twins in sectors like aerospace, where different companies’ twins (engine maker, airframe maker, airline’s operations) might interconnect for a holistic view. Efforts like the Digital Twin Consortium’s partnerships (e.g., with the Smart Cities Council digitaltwinconsortium.org) indicate a push toward shared twin ecosystems across organizations and regions. By 2025, it’s expected that more standardized “twin platforms” will allow companies to plug in various models and data sources, creating rich composite twins at larger scales.

- Edge and Real-Time Computing: To reduce latency and reliance on cloud connectivity, more twin deployments are happening at the edge (on or near the physical asset). This is crucial for time-sensitive applications – e.g., a wind turbine twin that can’t wait on cloud round-trips to adjust blade pitch in real time for gusts. Advancements in edge computing hardware (GPUs, IoT gateways) mean even complex simulations can run locally. We also see “hybrid twins” where heavy computations are done in the cloud but a lightweight model runs on the edge for immediate needs. The rollout of 5G networks further aids this trend by enabling high-bandwidth, low-latency data transfer from assets to edge/cloud, which is important for real-time twin updates (like in connected vehicles or remote robotics control).

- Personal Digital Twins and Consumer Use: While initially a B2B/industrial tech, the idea of personal digital twins is coming up. Tech visionaries suggest that individuals could have AI-driven digital versions of themselves to handle tasks or model their behavior. For example, Zoom’s CEO mused about AI “digital twin” avatars that could attend meetings on your behalf foxbusiness.com, businessinsider.com. Nvidia’s CEO Jensen Huang recently said that with advances in AI and biology, “our ability to have a digital twin of the human is plausible” in the foreseeable future laptopmag.com. This could revolutionize healthcare (as discussed) but also raises philosophical questions. In education, some foresee student twins to personalize learning. While still largely experimental, it’s a space to watch as AI capabilities progress – 2024 saw a flurry of discussions about AI “clones” for people in both work and personal life contexts.

- Sustainability and Climate Focus: There’s a strong trend of using digital twins to drive sustainability initiatives. From optimizing energy use in buildings and cities to designing greener products, twins are seen as key enablers for meeting climate targets. As noted, companies are using energy twins to cut carbon footprints digitaltwininsider.com. Another example is the concept of a digital twin of the Earth’s environment: in late 2024, Nvidia announced progress on its Earth-2 climate simulation platform aimed at ultra-high-resolution climate forecasting gamesbeat.com. Similarly, the European Union’s Destination Earth project is working on a planetary digital twin for climate policy testing. We can expect more public-private partnerships focusing on environmental twins – essentially using the tech to tackle global challenges like climate change, disaster resilience, and resource management.

- Government and Public Sector Investment: Governments are recognizing the strategic importance of digital twins. In the U.S., the 2022 CHIPS and Science Act included funding for advancing digital twin tech in manufacturing. In November 2024, the U.S. Department of Commerce announced a $285 million award (part of a $1 billion initiative) to establish a new institute focused on digital twins for semiconductor manufacturing nist.gov. This “SMART USA” institute aims to drive R&D in using twins to innovate chip design and production, indicating how critical the government views twins for the future of high-tech manufacturing nist.gov. Other countries like Singapore, China, and UAE are heavily investing in smart city twins and digital twin research hubs. Such support will likely accelerate breakthroughs and standardization in the field.

- Regulatory and Standards Evolution: With growing adoption, 2024–2025 is also seeing movement in developing standards and regulatory frameworks for digital twins. Organizations like ISO and IEEE have workgroups for digital twin terminology and reference architectures. Industries are formulating guidelines (for example, aviation regulators studying certification aspects of using digital twins in aircraft design). The presence of Digital Twin Consortium ambassadors in various regions digitaltwinconsortium.org suggests global collaboration to unify best practices. We anticipate clearer guidelines around data ownership for twins, model validation requirements (especially for safety-critical uses), and possibly certifications for twin solutions. As these frameworks solidify, it will build confidence for wider adoption, especially in risk-averse sectors.

In essence, digital twins are moving towards being more intelligent, more immersive, and more integrated. They’re not static digital models; they’re becoming living, learning systems that will work hand-in-hand with humans and AI agents. The term “twin” might even evolve as these systems gain their own agency (some say “cognitive digital twins” for AI-imbued ones). Another expert quipped that digital twins are crucial for the coming era because “everything that moves will be robotic” and those robots will need virtual counterparts for design and management laptopmag.com. That speaks to the intertwined future of robotics, AI, and twins.

Overall, the trajectory points to digital twin technology being a foundational element of the digital transformation of industries, akin to how the internet or cloud became foundational in prior decades. As we instrument more of the physical world and model it, the boundary between reality and simulation will further blur – offering tremendous opportunities to optimize and innovate, provided we handle the journey responsibly.

Noteworthy News and Breakthroughs (2024–2025)

The past two years have seen many high-profile digital twin projects and announcements. Here are a few noteworthy developments highlighting the momentum in this space:

- Orlando’s Regional Digital Twin: As mentioned earlier, the Orlando Economic Partnership unveiled one of the largest 3D city digital twins to date, covering 800 sq. miles of the Orlando region xrtoday.com. Completed in 2023 in collaboration with Unity Technologies, this twin integrates real-time data for transportation, utilities, and more. In 2024, Fast Company recognized Orlando’s twin as a “Next Big Thing in Tech”, underscoring how it’s pushing boundaries in economic development and urban planning xrtoday.com. The project is used to attract businesses by giving them an immersive tour of the region’s data, and to address urban challenges (traffic, climate adaptation) via simulation xrtoday.com. Orlando’s success may serve as a model for other cities; indeed, the global race to build smart city twins is on.

- $1B U.S. Investment in Semiconductor Twins (SMART USA): In late 2024, the U.S. government (under the CHIPS Act) announced a major initiative to establish a Manufacturing USA institute dedicated to digital twin technology for semiconductors nist.gov. The institute, to be based in North Carolina and dubbed SMART USA, will focus on developing and using twins to improve chip design and manufacturing processes nist.gov. The goal is to boost domestic semiconductor innovation by leveraging twins to simulate and optimize fabrication steps, potentially shortening development cycles for new chips and improving yields. Commerce Secretary Gina Raimondo highlighted that these “new Digital Twin capabilities” will enable collaboration with experts globally and spur the next frontier of semiconductor tech nist.gov. This move not only injects funding into twin R&D but also signals a strategic prioritization of digital twins at a national policy level.

- Siemens & NVIDIA Partnership for Industrial Metaverse: In 2022–2023, engineering giant Siemens AG and graphics leader NVIDIA announced a partnership to connect Siemens Xcelerator (its digital twin platform) with NVIDIA’s Omniverse. Throughout 2023–2024, updates from this collaboration showed Siemens using NVIDIA’s AI and visualization tech to enhance its industrial twins. One outcome described in 2024 was Siemens integrating Omniverse’s real-time ray-tracing to create a “Digital Reality Viewer” within its Teamcenter PLM software, allowing photorealistic visualization of product twins via the cloud nvidia.com. They also reported that connecting simulation tools to NVIDIA’s generative AI enabled engineers to use AI within their workflows nvidia.com. In a related vein, Siemens teamed up with Sony to develop an AR/VR headset (revealed at CES 2024) aimed at immersive engineering with digital twins designnews.com. These efforts garnered attention as steps toward an industrial metaverse where multiple company tools interoperate in a shared virtual space. It underscores how major tech companies are coalescing around digital twin ecosystems.

- Bentley Systems & Google Geospatial Partnership: In October 2024, infrastructure software company Bentley Systems announced a strategic partnership with Google to integrate Google Maps Platform’s high-quality 2D and 3D geospatial data (like photorealistic 3D Tiles of cities) into Bentley’s infrastructure digital twins manufacturingdigital.com. By bringing Google’s rich mapping data into engineering models, this move enhances the context and realism of twins for roads, railways, utilities, and buildings. Engineers can now situate their project’s twin within an accurate digital replica of the surrounding environment, improving design decisions and stakeholder presentations. This partnership highlights the trend of convergence between traditional GIS data and IoT-driven twins, and how tech giants (Google in this case) are entering the twin arena via their data assets.

- Unity’s Push into Digital Twins: Unity, known for its game engine, has been expanding into enterprise solutions. In 2023, Unity appointed a VP of Digital Twins and started showcasing how its real-time 3D engine can power twins (like the Orlando project). In April 2024, Unity’s Digital Twins head Dave Rhodes demonstrated how Unity will incorporate AI, machine learning, and analytics to broaden twin use cases at the Orlando project xrtoday.com. Unity’s involvement is notable because it brings high-end visualization and a huge developer community to the table, potentially accelerating the creation of interactive twins for factories, buildings, and cities by making it easier for developers to build on a familiar platform.

- Healthcare Twin Collaborations: In healthcare, an interesting partnership formed between Siemens Healthineers and Medical University of South Carolina (MUSC) aiming to develop digital twin solutions for hospitals and patient care pathways. By 2024, this collaboration reported progress in using twins to optimize hospital operations and even to model certain patient treatment processes research.aimultiple.com. While still early, it’s a sign of academia and industry teaming up to validate twin technology in clinical settings. Another healthcare update: startups and big tech alike are exploring “virtual patient” initiatives – for example, in 2024, a well-funded startup was working on a digital twin of the human immune system to test drug responses virtually, reflecting growing interest in the biotech sector.

- Auto Manufacturing and Omniverse: In the automotive world, BMW Group made headlines for its digital twin efforts. BMW has built a replica of an entire car factory in NVIDIA Omniverse to simulate production (an initiative that started in 2021 and expanded). In mid-2024, BMW announced that using this virtual factory twin has led to an estimated 30% efficiency gain in planning and a reduction in on-site change orders during construction digitaltwininsider.com. Essentially, by perfecting assembly line setups in the digital twin first, they saved real-world time and cost. BMW’s success story has spurred others – e.g., Toyota and Jaguar Land Rover have since partnered with chip companies to do similar, and we saw Ford Motor collaborate on a predictive twin to cut costs by a few percent in their operations digitaltwininsider.com. These are relatively small percentages, but in automotive margins, they’re substantial. It’s noteworthy how quickly these techniques are being adopted across the industry.

- Public Sector Digital Twin Hubs: 2024 saw a few national-level digital twin hubs being launched. For instance, the UK established a National Digital Twin programme under its Centre for Digital Built Britain, aiming to create an information management framework to connect twins of infrastructure nationally (continuing work from previous years but gaining traction in ’24). Similarly, Australia began developing a digital twin of its electricity market to better plan the transition to renewables. These efforts might not be splashy in headlines, but they indicate a serious institutionalization of twin tech in public planning.

- Digital Twin in Space and Defense: A quick notable from defense: In late 2023, the U.S. Air Force opened a tender for a “Operational Twin” concept to model entire mission theaters digitally for training AI in simulated warfare. Meanwhile, in space, companies like Lockheed Martin are now delivering satellites with digital twin models that live on Earth for continuous monitoring of the satellite’s status. NASA, too, in 2025 announced plans for a comprehensive Mars habitat digital twin to assist astronauts in future manned missions. These illustrate how even in highly sensitive fields, twins are becoming essential infrastructure.

Each week seems to bring new digital twin news – whether it’s a startup raising funds for a novel twin platform or a city announcing a digital twin project. The examples above give a flavor of the scale (cities, nations, global companies) and scope (from chips to climate to healthcare) involved. It’s an exciting time where pioneering projects are validating the technology and inspiring others. As one executive quipped, “Digital twins are quickly becoming a staple solution” in enterprise XR and IoT deployments across the board xrtoday.com.

With so much momentum, the coming years will likely see digital twins move from special projects to standard operating tools in many organizations.

Conclusion

Digital twins have emerged from the realm of high-tech buzzwords to become a practical, game-changing tool across industries. In 2025, they stand at the intersection of our physical and digital worlds – providing a bridge that allows us to understand, predict, and improve real-world outcomes through virtual models. A digital twin can be as simple as a data-fed 3D model of a single machine, or as complex as a fully simulated city or human organ. In all cases, the core idea is the same: by mirroring reality in a digital medium, we gain superpowers in how we design, operate, and interact with that reality.

The journey of digital twins – from NASA’s lifesaving simulations during Apollo 13 to today’s AI-driven, immersive models – highlights a broader narrative of technological progress. It exemplifies how better data and computing can unlock value that was previously hidden in the complexity of the physical world. As this report outlined, the benefits are impressive: cost savings, efficiency gains, predictive insights, and the ability to test decisions without real risk. It’s little wonder that surveys show an overwhelming majority of large enterprises are either exploring or already investing in digital twins mckinsey.com. In the words of McKinsey analysts, 70% of C-suite tech executives at big companies are on board with twin initiatives mckinsey.com – a strong endorsement from the top.

Yet, harnessing the full potential of digital twins will require careful navigation of challenges. Data, security, and ethics cannot be afterthoughts. Trust is the currency of the digital future, and whether it’s a city trusting the twin with its citizens’ data or a patient trusting a twin with their health, maintaining that trust through transparency and safeguards is paramount. Industry leaders acknowledge this responsibility: for example, leaders in the field emphasize building privacy and security “by design” into twin systems to preempt issues bradley.com.

Looking ahead, the trend is clear – our world is becoming richly instrumented and modelled. We are likely heading toward an era where every significant physical entity has a dynamic digital counterpart. That might mean entire smart cities constantly self-optimizing via their twins, manufacturing plants that largely run themselves through autonomous twin feedback loops, or even personal wellness twins that help individuals manage their health. Technologies like 5G/6G, edge computing, and next-gen AI will only accelerate this integration. As Jensen Huang’s quote earlier hinted, the line between science fiction and reality is thinning: the once “outlandish” idea of simulating a whole human is now on the industry’s plausible roadmap laptopmag.com.

In conclusion, digital twin technology represents a powerful paradigm shift in how we approach problem-solving and innovation. By fusing the virtual and physical, it allows us to fail fast, learn fast, and optimize continually in the digital realm – to ultimately succeed in the real world. Companies and governments that leverage this tool wisely will be better equipped to navigate the complexities of modern industry and society. As this technology matures, we can expect it to play a central role in addressing some of our biggest challenges, from climate adaptation to healthcare personalization. The digital twin revolution is well underway, and its impact is already being felt in tangible improvements around us. The coming years will show just how far this synergy of bits and atoms can take us – ushering in a future where innovation has a twin.

Sources:

- Expeditors – “Rise of the Digital Twin: How Lessons Learned from NASA…” info.expeditors.cominfo.expeditors.com

- McKinsey Explainer (2024) – “What is digital-twin technology?” mckinsey.commckinsey.com

- Wikipedia – “Digital twin” (history and definition) en.wikipedia.org

- Simio (2025) – “How Will Digital Twins Software Transform Your Business in 2025?” simio.comsimio.com

- Bradley (Reuters Legal, 2024) – “Avoiding growing pains in the development and use of digital twins” bradley.combradley.com

- AIMultiple Research (2025) – “15 Digital Twin Applications by Industry” research.aimultiple.comresearch.aimultiple.com

- Gray Insights (2023) – “Digital Twins: An Emerging Force in the Digital Economy” gray.comgray.com

- Design News (2024) – “CES 2024 Keynote: AI, Digital Twins Set to Transform Lives” designnews.comdesignnews.com

- Digital Twin Insider (2024) – “The Performance of Digital Twins Across Industry” digitaltwininsider.comdigitaltwininsider.com

- XR Today (2023) – “Orlando’s Breakthrough Digital Twin Project Named 2024 Top Tech” xrtoday.comxrtoday.com

- NIST News (2024) – “$285M Award for CHIPS Institute for Digital Twins” nist.govnist.gov

- Jensen Huang Interview – Laptop Mag (2025) laptopmag.com (Nvidia CEO on human digital twins)